Flue gas denitration reaction system

A reaction system and flue gas technology, applied in the field of flue gas denitrification reaction system, can solve the problems of complex and changeable flow field, concentration deviation, large denitration flue gas volume, etc., so as to improve denitration efficiency, improve utilization efficiency, and improve economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Baseline conditions: using honeycomb catalyst, NO in the flue gas to be treated x Concentration 550mg / m 3 , O 2 The content is 3.5%, the reaction temperature is 370°C, and the ammonia nitrogen ratio is 0.85.

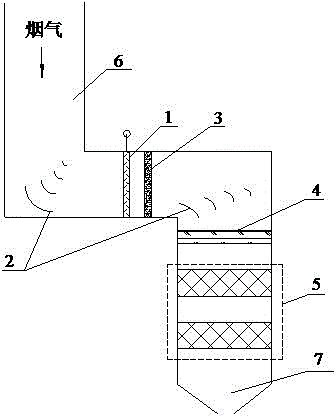

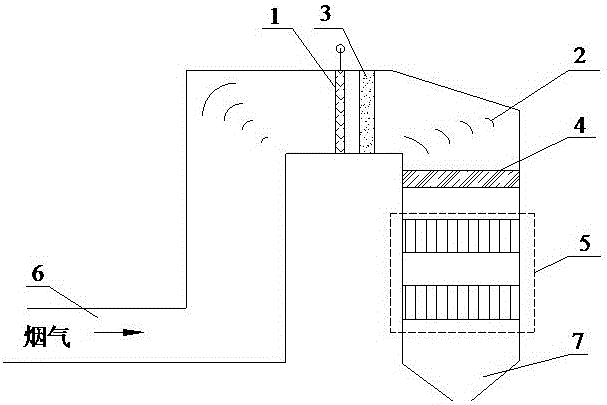

[0028] refer to figure 1 , a traditional flue gas denitrification reaction system, including an ammonia injection grid 1, a deflector 2, a static mixer 3, a rectification grid 4, and a catalyst layer 5, and the ammonia injection grid and the catalyst layer are sequentially arranged along the flow direction of the flue gas In the flue, the ammonia injection grid is connected to the inlet flue 6, the catalyst layer is connected to the outlet flue 7, the deflector is arranged at the corner of the flue, and the rectifying grill is arranged on the In the inlet section of the catalyst layer, the static mixer is arranged between the ammonia injection grid and the rectifying grid.

[0029] Both the inlet flue and the outlet flue are vertical flues; the ammonia injecti...

Embodiment 2

[0039] The reference conditions are the same as in Example 1.

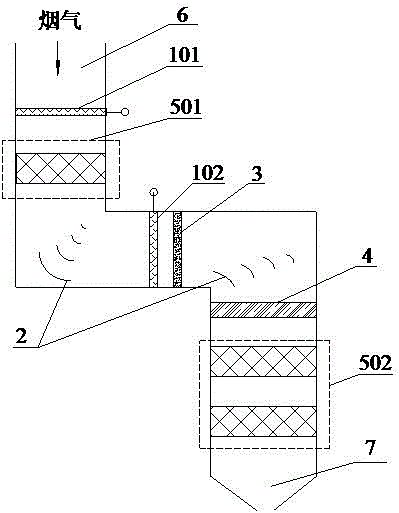

[0040] refer to figure 2 , the difference between the flue gas denitrification reaction system described in this embodiment and embodiment 2 is:

[0041] The ammonia injection amount of the first ammonia injection grid accounts for 30-50wt% of the total amount of ammonia injection under the reference conditions, and the remaining ammonia gas is injected into the flue through the second ammonia injection grid.

[0042] Test the denitrification efficiency of the system of the present invention reaches 90.8%, and the amount of ammonia escape is 1.8mg / m 3 .

Embodiment 3

[0044] The reference conditions are the same as in Example 1.

[0045] refer to figure 2 , the difference between the flue gas denitrification reaction system described in this embodiment and embodiment 2 is:

[0046] The catalyst loading in the catalyst pre-reaction zone accounts for 10-30 wt% of the total catalyst loading under the reference conditions, and the remaining catalyst is loaded in the catalyst main reaction zone.

[0047] It is measured that the denitrification efficiency of the system reaches 91.6%, and the ammonia escape amount is 1.7mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com