Ultralow-emission denitration equipment for cement production

An ultra-low, denitrification technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of incomplete flue gas denitration, decreased denitration efficiency, and easily blocked SCR denitration catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

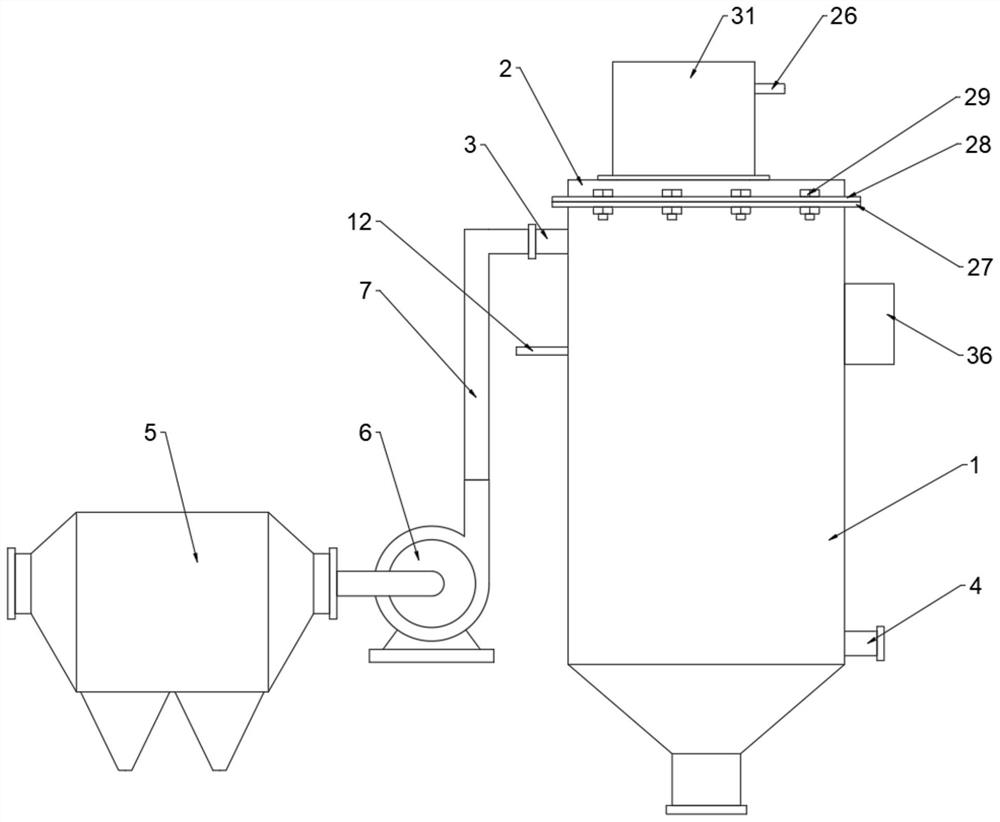

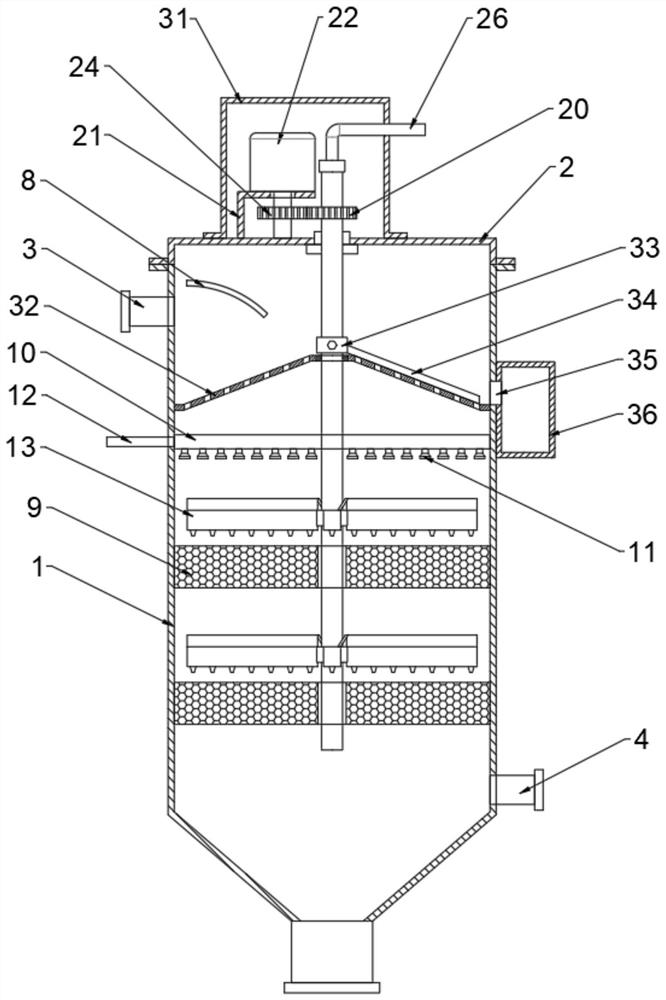

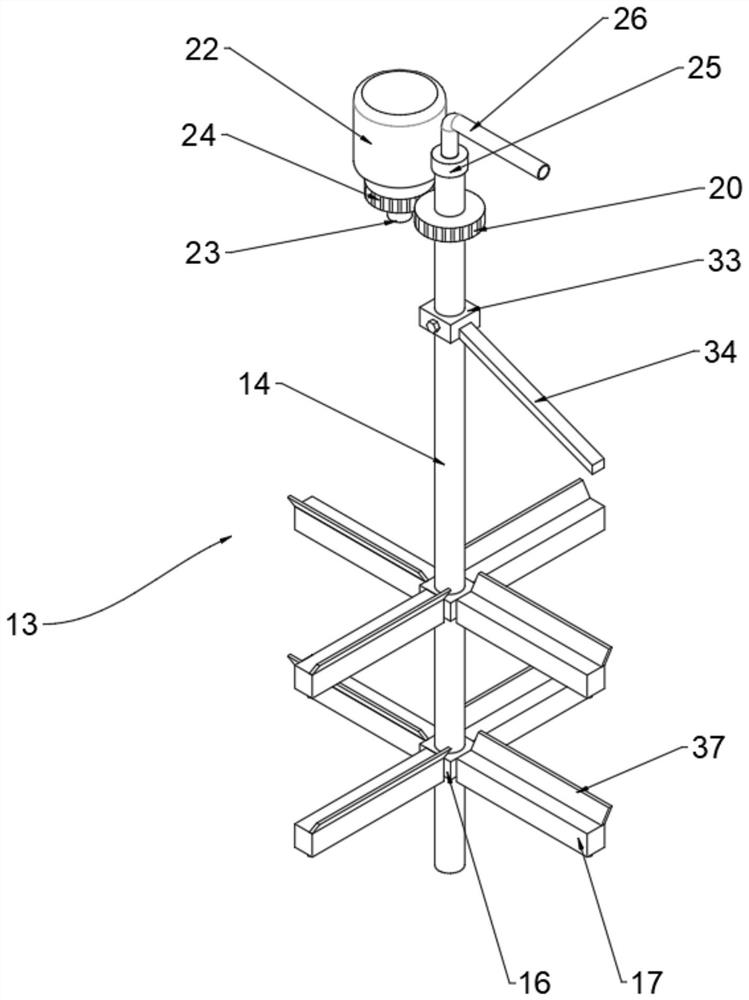

[0029] Embodiment one, by Figure 1-Figure 6 Given, the present invention includes a reaction cylinder 1, the upper end of the reaction cylinder 1 is connected with a cylinder cover 2, the upper side of the reaction cylinder 1 is connected with an air inlet pipe 3, the lower part of one end of the reaction cylinder 1 is connected with an outlet pipe 4, and one side of the reaction cylinder 1 is installed There is an electric precipitator 5, the output end of the electric precipitator 5 is connected with a fan 6, and the output end of the fan 6 is connected with the air inlet pipe 3 through the smoke pipe 7, and the side of the air inlet pipe 3 is connected with a slow flow pipe relative to the inside of the reaction cylinder 1. A catalyst layer 9 is uniformly connected to the inside of the plate 8 and the reaction cylinder 1, and an ammonia injection pipeline 10 is connected above the catalyst layer 9, and an atomizing nozzle 11 is evenly installed at the lower end of the ammon...

Embodiment 2

[0031] Embodiment 2, on the basis of Embodiment 1, the upper end of the reaction cylinder 1 is welded with a first flange ring 27, the lower end of the cylinder cover 2 is connected with a second flange ring 28, the first flange ring 27 and the second flange ring 28 is connected by bolts 29, and the first flange ring 27 and the second flange ring 28 are fixed under the connection of bolts 29, so that the cylinder cover 2 and the reaction cylinder 1 can be opened and closed conveniently, and then it is convenient to check the inside of the reaction cylinder 1. Component repair and maintenance.

Embodiment 3

[0032] Embodiment 3, on the basis of Embodiment 1, the inner upper wall of the bronchial cavity 18 is evenly connected with a deflector 30, and the deflector 30 gradually grows obliquely along the airflow blowing direction, and the main air cavity can be divided by the deflector 30. The airflow flowing in the channel 15 is directed downwards so that the airflow blows downwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com