Flue gas cyclone mixing device of SCR denitration system

A swirling mixing and swirling mixer technology, applied in fluid mixers, gas and gas/steam mixing, mixers, etc., can solve the problem of large ammonia escape, blockage of air preheater, flue gas and diluted ammonia Insufficient air mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

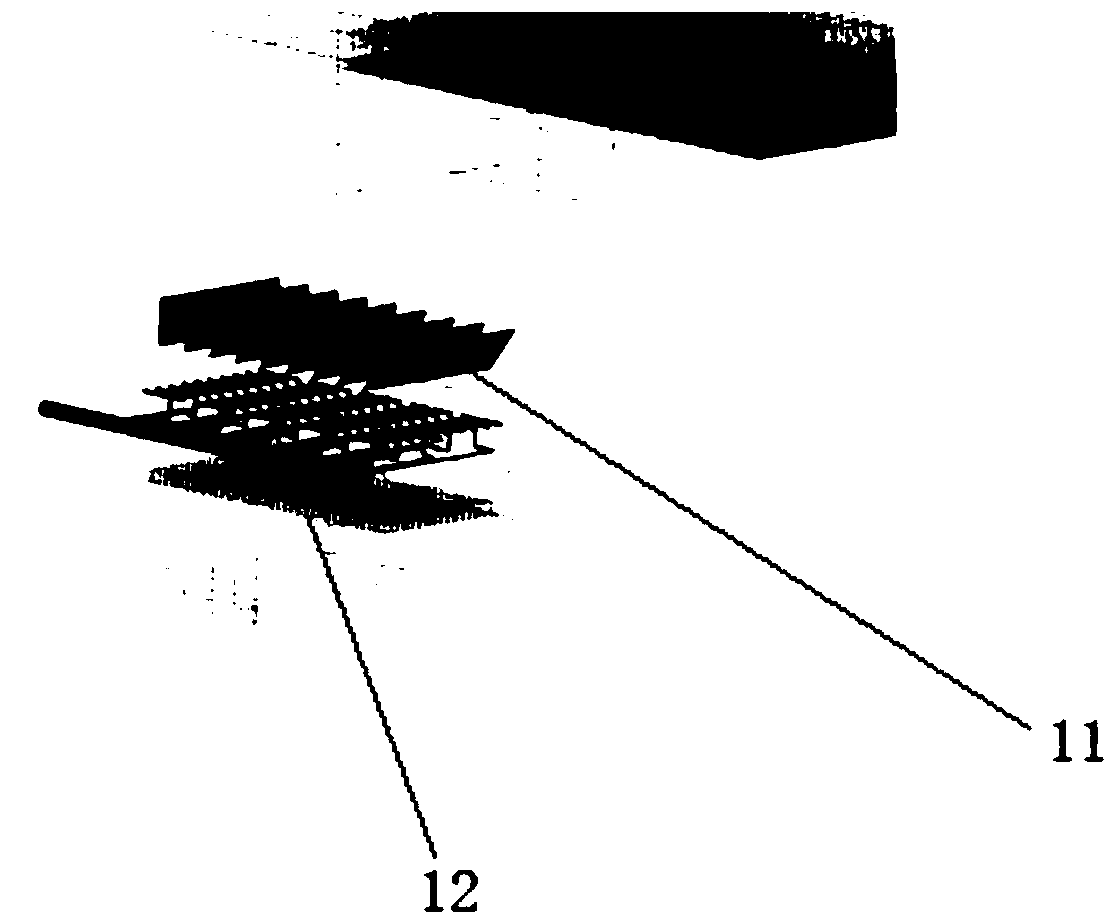

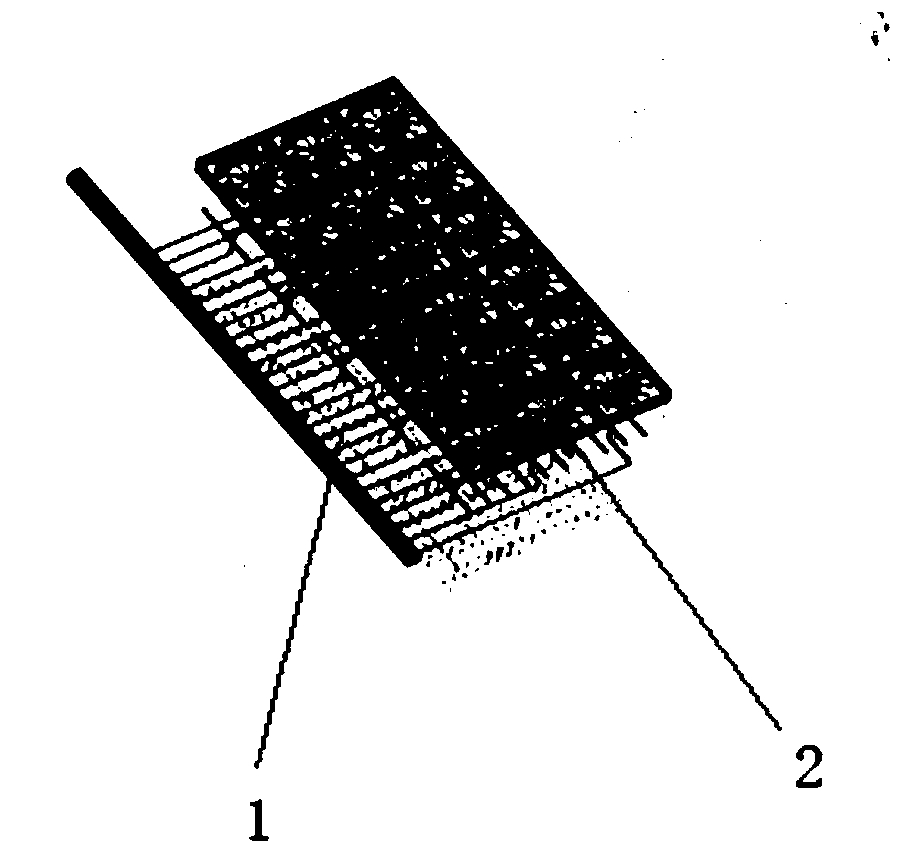

[0017] ginseng figure 2 , image 3 As shown, this embodiment provides a SCR denitration system flue gas swirl mixing device, including a swirl mixer uniform device 2 arranged behind the ammonia injection branch pipe 1 along the flue gas flow direction, and the swirl mixer uniform device 2 consists of A plurality of swirl mixers are arranged in a flat manner, and the swirl mixer is arranged opposite to the ammonia injection branch pipe 1 to cover the diluted ammonia gas sprayed from the ammonia injection branch pipe 1;

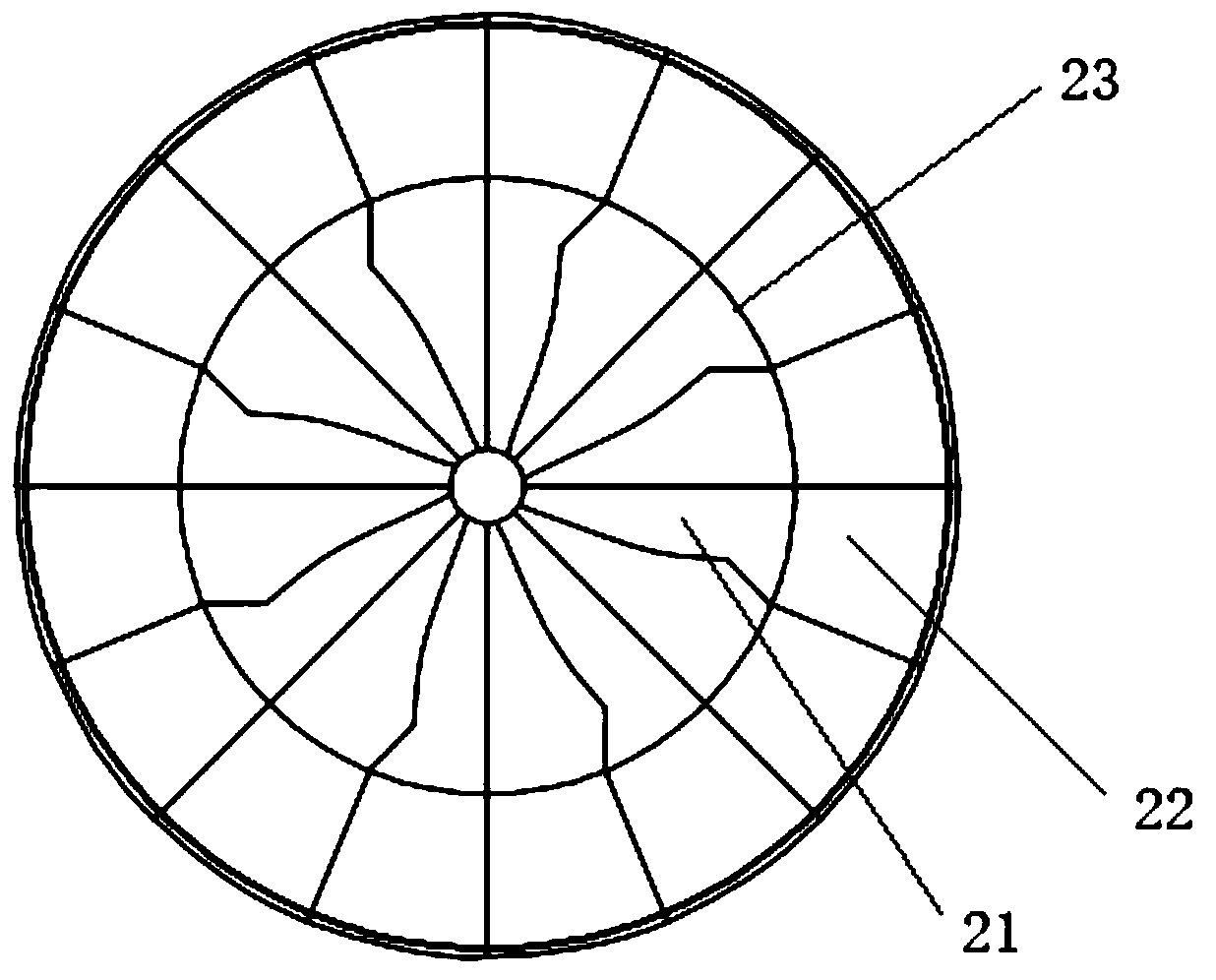

[0018] The swirl mixer is composed of inner swirl blades 21 and outer swirl blades 22. The rotation directions of the two sets of swirl blades are oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com