Flue gas denitration flow field simulation checking method and system

A flow field and flue gas technology, applied in the field of flue gas denitrification, can solve problems not involved in the calibration calculation process, and achieve the effect of improving the efficiency of denitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

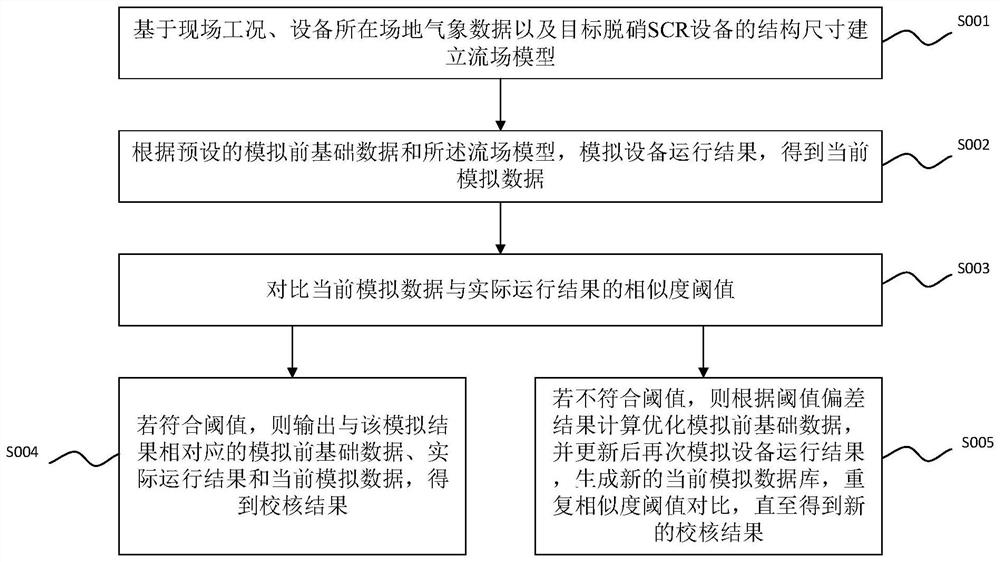

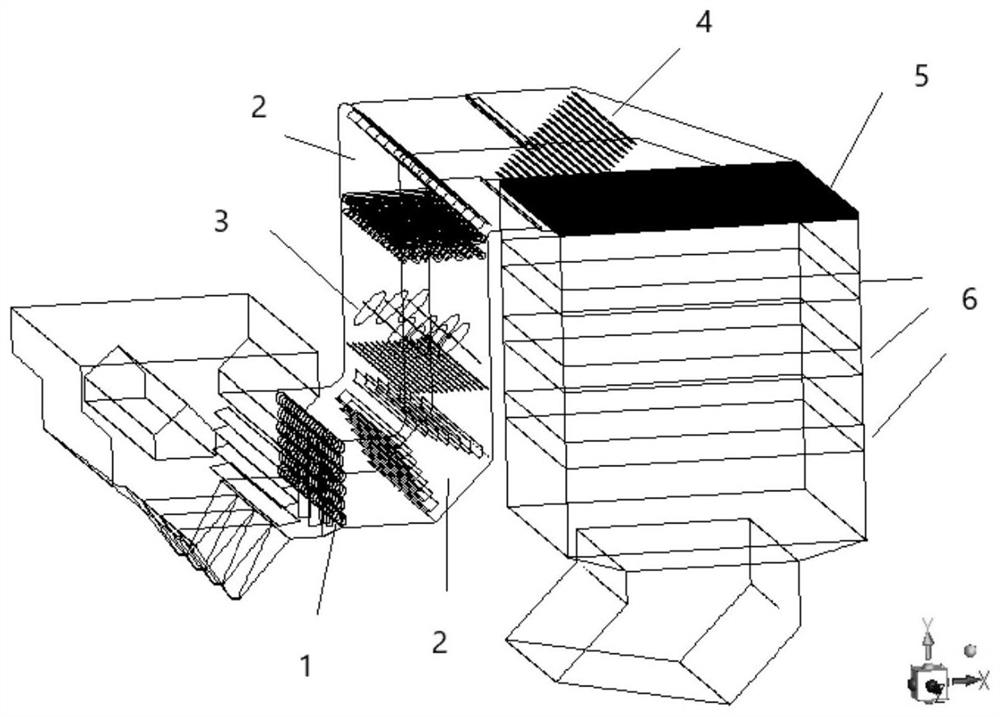

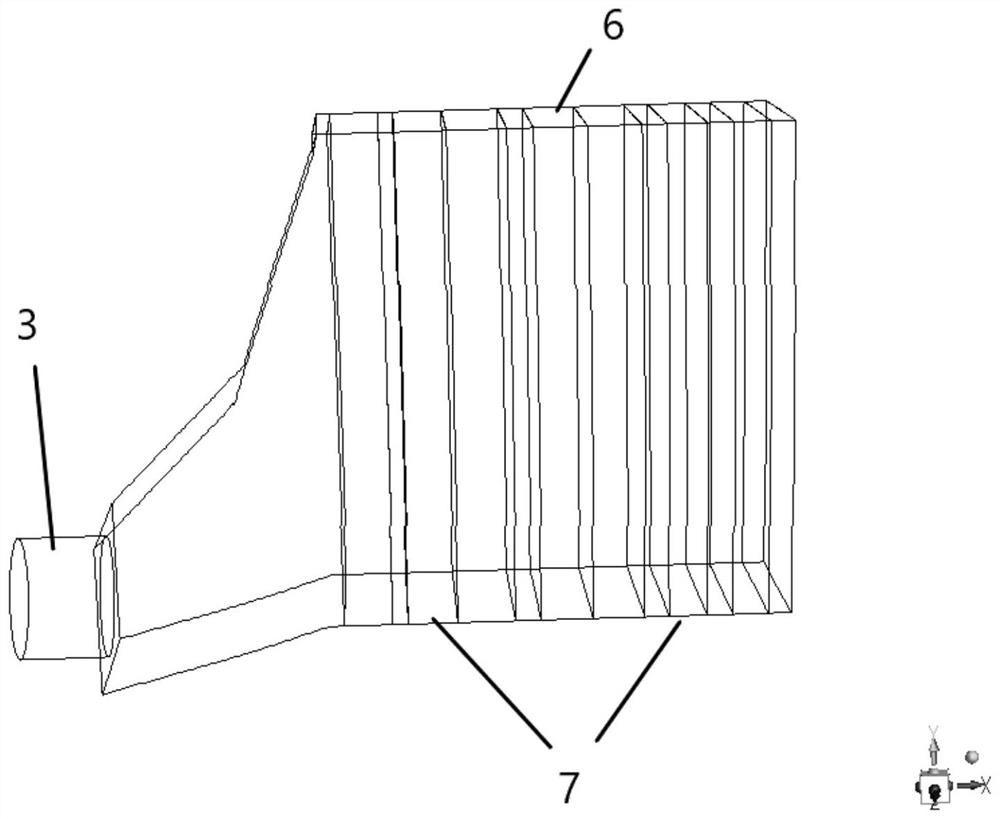

[0040] see figure 1 , the embodiment of the present invention discloses a denitrification flow field simulation verification method, wherein devices with the same reaction principle as denitrification devices such as the tail flue of the coal-fired unit and the waste heat boiler of the gas unit can use the flow field simulation verification method herein.

[0041] Include the following steps:

[0042] S001, preset a pre-simulation basic database for storing pre-simulation basic data and an actual operation result database for storing actual operation results.

[0043] When simulating and verifying the SCR flow field of the tail flue of a coal-fired unit, the basic database before the simulation includes: flue gas conditions at the inlet of the denitrification device, such as flue gas volume,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com