Circulating fluidized bed boiler and in-furnace SNCR denitration device and process

A circulating fluidized bed and boiler furnace technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of prolonged combustion time at low load, low denitration efficiency, and high dust concentration, reducing consumption and Operating cost, improvement of furnace reaction efficiency, and effect of improving denitration reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

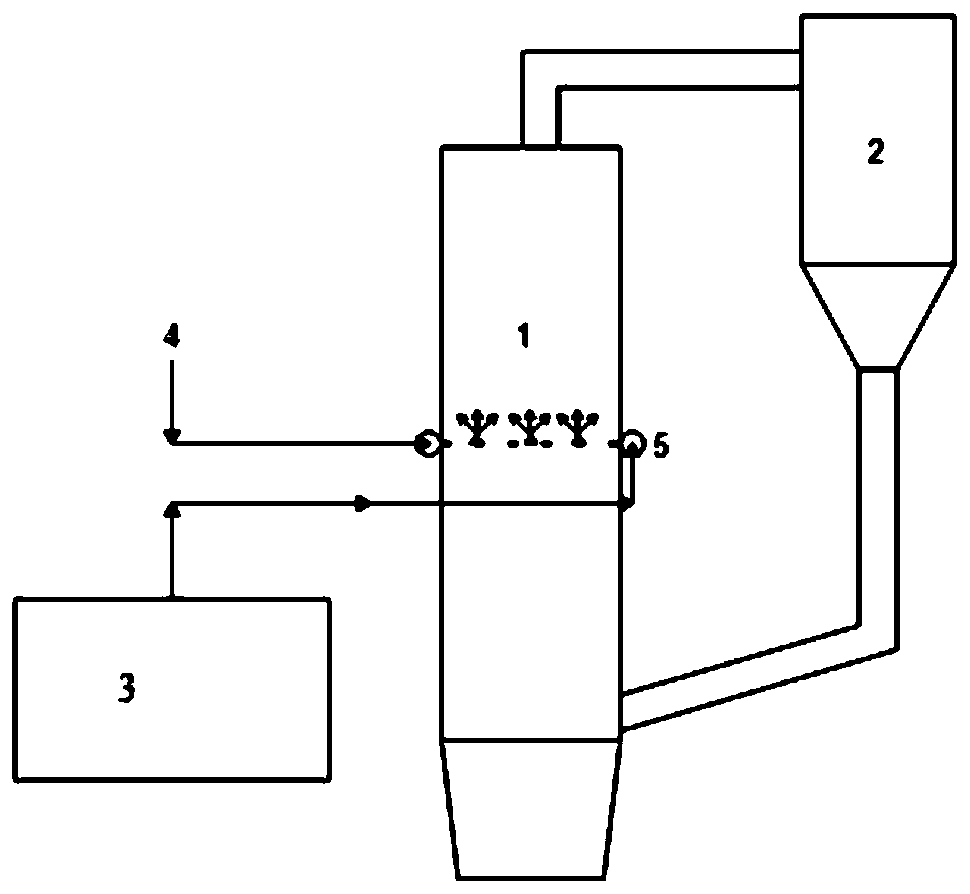

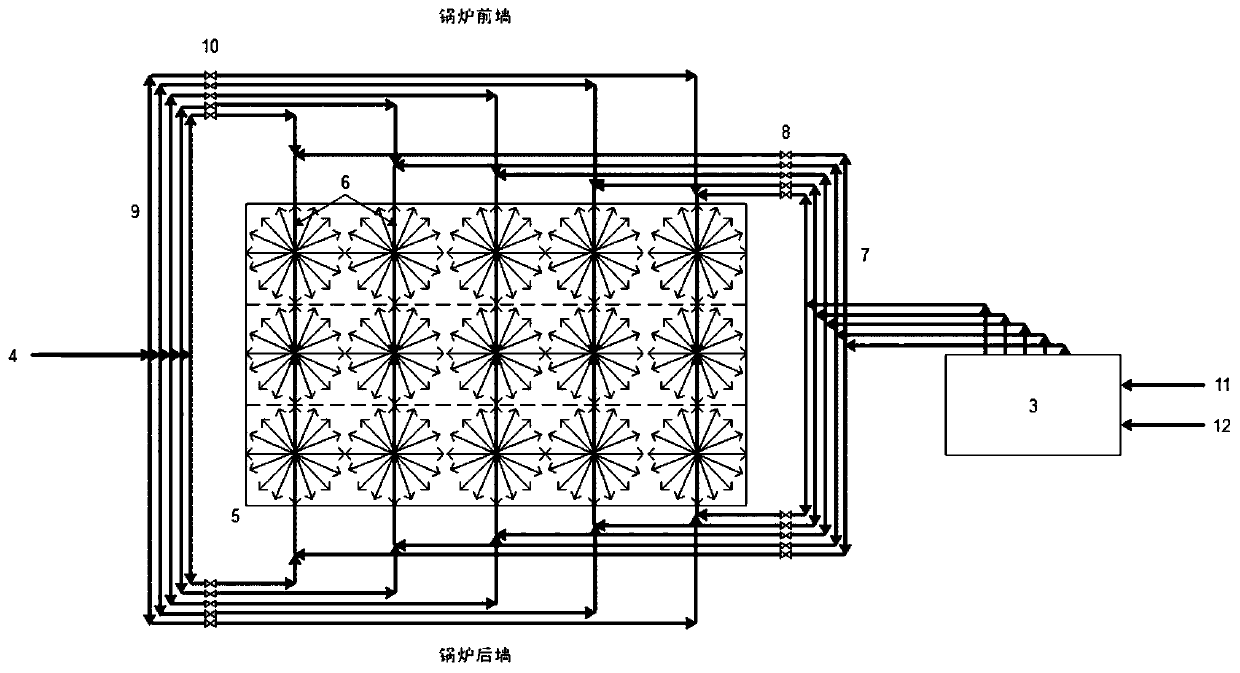

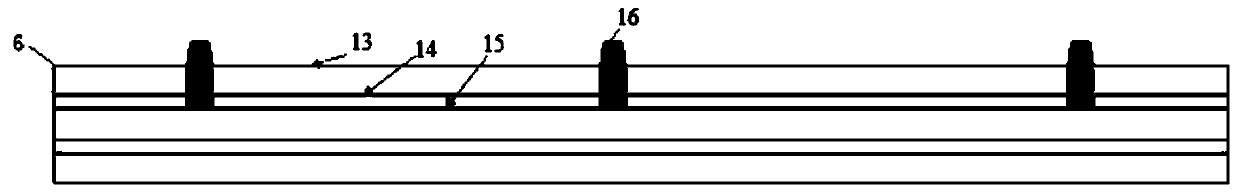

[0029] Such as figure 1 and figure 2 As shown, an SNCR denitrification device in a circulating fluidized bed boiler includes an injection system 5, the medium inlet of the injection system 5 is connected to the cooling air system 4, the urea delivery pipeline and the compressed air delivery pipeline, and the injection system 5 includes several multi-point The continuous injection device 6, the multi-point continuous injection device 6 is coaxially provided with the injection device casing 13, the compressed air pipeline 14 and the urea solution pipeline 15 from the outside to the inside, and several injection nozzles are arranged along the axial direction of the multi-point continuous injection device 6. Device atomization nozzle 16, spray device atomization nozzle 16 communicates with injection device casing 13, compressed air pipeline 14 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com