Wear-resistant low-floating fiber glass fiber-reinforced polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and floating fiber glass fiber, which is applied in the field of polymer material modification, can solve the problems of difficult to meet the appearance and use requirements of precision parts, large amount of wear-resistant agent added, and limited application expansion, etc., to achieve production efficiency High, reduce the amount of wear-resistant agent used, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

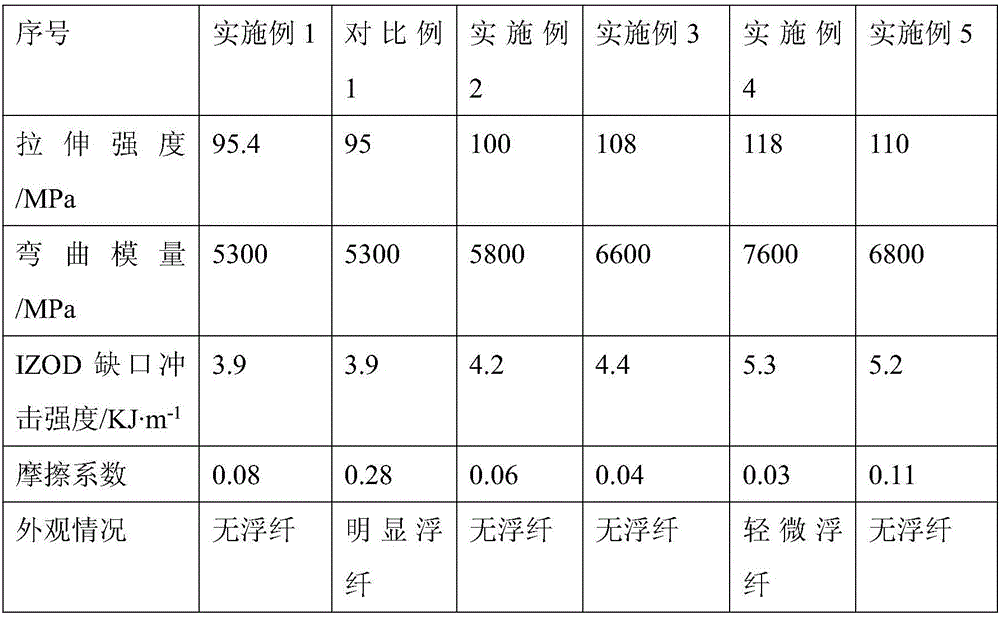

Examples

Embodiment 1

[0043] 1 Preparation of wear-resistant and anti-floating fiber masterbatch

[0044] Take 74 parts of PPS1150C, 15 parts of molybdenum disulfide, 10 parts of graphite, 1680.2 parts of antioxidant, 0.2 parts of light stabilizer V703, 0.3 parts of compatibilizer EMA-g-MAH, 0.3 parts of lubricant EBS, The above materials are uniformly mixed in a high-speed mixer, and then the mixture is melted and extruded through a twin-screw extruder, and finally cooled and dried to obtain abrasion-resistant and anti-floating fiber masterbatch. Among them, the processing temperature from zone 1 to zone 9 are 200℃, 260℃, 270℃, 280℃, 280℃, 285℃, 285℃, 290℃, 290℃, the speed is 280r / min, and the feeding speed is 20r / min.

[0045] 2 Preparation of wear-resistant low-floating fiber glass fiber reinforced polyphenylene sulfide composite material

[0046] Take 8 parts by weight of the abrasion and anti-floating fiber masterbatch prepared above, 72 parts of polyphenylene sulfide 1110C, 18 parts of continuous...

Embodiment 2

[0050] 1 Preparation of wear-resistant and anti-floating fiber masterbatch

[0051] Take 65 parts of PPS1170C, 16.5 parts of molybdenum disulfide, 17 parts of graphite, 0.4 parts of antioxidants 412s, 1680.3 parts of antioxidants, 0.5 parts of compatibilizer EMA-g-MAH, and 0.3 parts of lubricant EBS. The above materials are uniformly mixed in a high-speed mixer, and then the mixture is melted and extruded through a twin-screw extruder, and finally cooled and dried to obtain abrasion-resistant and anti-floating fiber masterbatch. Among them, the processing temperature from zone 1 to zone 9 are 200℃, 260℃, 270℃, 280℃, 280℃, 285℃, 285℃, 290℃, 290℃, the speed is 280r / min, and the feeding speed is 20r / min.

[0052] 2 Preparation of wear-resistant low-floating fiber glass fiber reinforced polyphenylene sulfide composite material

[0053] Take 12 parts by weight of the abrasion-resistant and anti-floating fiber masterbatch prepared above, 61 parts of polyphenylene sulfide 1130C, 25 parts...

Embodiment 3

[0055] 1 Preparation of wear-resistant and anti-floating fiber masterbatch

[0056] Take 60 parts of PPS1190C, 20 parts of molybdenum disulfide, 18 parts of graphite, 1680.5 parts of antioxidants, 10100.4 parts of antioxidants, 0.6 parts of compatibilizer EMA-g-MAH, and 0.5 parts of lubricant EBS by weight. The materials are uniformly mixed in a high-speed mixer, and then the mixture is melted and extruded through a twin-screw extruder, and finally cooled and dried to obtain abrasion-resistant and anti-floating fiber masterbatch. Among them, the processing temperature from zone 1 to zone 9 are 200℃, 260℃, 270℃, 280℃, 280℃, 285℃, 285℃, 290℃, 290℃, the speed is 280r / min, and the feeding speed is 20r / min.

[0057] 2 Preparation of wear-resistant low-floating fiber glass fiber reinforced polyphenylene sulfide composite material

[0058] Take 15 parts by weight of the abrasion-resistant and anti-floating fiber masterbatch prepared above, 53 parts of polyphenylene sulfide 1H30C, 30 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com