Automatic spaceflight high-pressure inflation and deflation system and method

An aerospace automation, inflation and deflation technology, which is applied to the container filling method, the container discharge method, the equipment discharged from the pressure vessel, etc., can solve the problems of insufficient intelligence, low error tolerance rate of personnel operation, and many types of valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

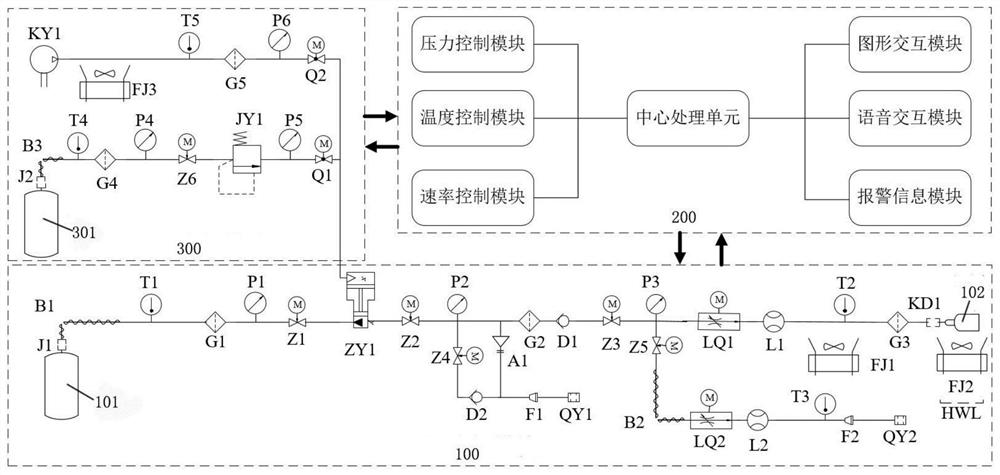

[0054] Such as figure 1 As shown, a kind of aerospace automatic high-pressure inflation and deflation system of the present embodiment includes a gas addition module 100, a driving gas module 300 and a control module 200; the gas addition module 100 includes a first standard gas cylinder 101, a target gas bottle 102 and an additional gas pipeline, a booster pump ZY1 is provided on the additional gas pipeline; the two ends of the additional gas pipeline are respectively connected to the first standard gas cylinder 101 and the target gas cylinder 102, and are used to convert the first The gas in the standard gas cylinder 101 is added to the target gas cylinder 102; the driving gas module is connected with the booster pump ZY1 through the driving gas pipeline;

[0055] A pressure detection component, a pressure regulation component, a temperature detection component and a temperature regulation mechanism are arranged on the added gas pipeline, and the pressure detection component...

Embodiment 2

[0068] Such as figure 1 As shown, on the basis of Embodiment 1, a first flow sensor L1 and a first flow regulating valve LQ1 are also provided on the added gas pipeline of this embodiment, and the first flow sensor L1 is used to collect the added gas The first gas flow signal in the gas pipeline is sent to the control module 200; the control module 200 controls the opening of the first flow regulating valve LQ1 according to the inflation pressure change rate and the first gas flow signal, While the rate of change of the inflation pressure of the additional gas pipeline is within a preset safe range, the gas flow rate of the additional gas pipeline is within a safe range of inflation flow. By setting the first flow sensor and the first flow regulating valve, the flow on the additional gas pipeline can be monitored, and the rate of change of the inflation pressure calculated according to the first gas pressure signal and the size of the gas flow signal collected by the flow sens...

Embodiment 3

[0070] Such as figure 1 As shown, on the basis of Embodiment 1 or Embodiment 2, the additional gas pipeline of this embodiment is also connected with a safety pressure relief pipeline, a first bleed pipeline, a first one-way valve D1 and a second bleed valve. The air pipeline, the safety relief pipeline and the first air release pipeline are located upstream of the first one-way valve D1 and downstream of the second pressure sensor P2; the third pressure regulating valve Z3 and the The second air release pipeline is located downstream of the first one-way valve D1, and the second air release pipeline is located upstream of the third pressure sensor P3; a safety valve A1 is connected to the safety pressure relief pipeline, The safety valve A1 is connected to the control module 200, and the control module 200 is used to control the safety valve A1 to open and release pressure when the first gas pressure signal exceeds a safety threshold; the first gas release pipeline It is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com