Antibacterial finishing auxiliary of woolen sweater

A technology for antibacterial finishing and woolen sweaters, which can be used in fiber processing, textiles and papermaking, animal fibers, etc. It can solve the problems of complex operation, high cost, and high technical requirements, and achieve high energy, low price, and good palatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

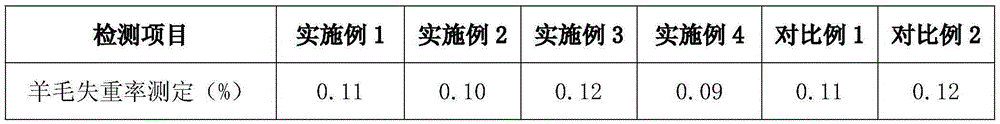

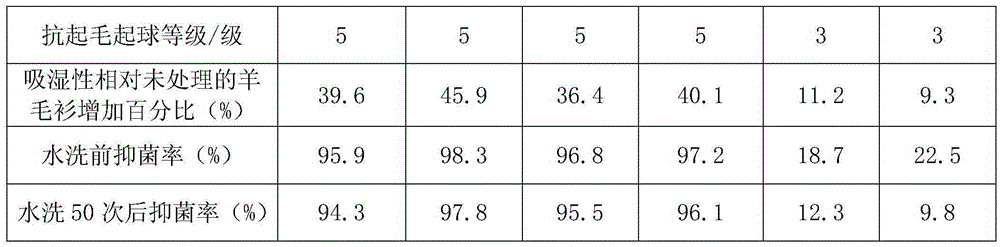

Examples

Embodiment 1

[0018] The use of antibacterial finishing additives for woolen sweaters:

[0019] (1) Select high-quality wool fibers and weave them into garments;

[0020] (2) Finishing:

[0021] a. Preprocessing:

[0022] Pretreatment protein solution: according to mass percentage, hydrolyzed feather powder 0.05%, corn gluten powder 0.05%, trehalose 0.5%;

[0023] Pretreatment: Spray the pretreated protein solution evenly on the woolen sweater, the spraying weight is 0.2 times the weight of the woolen sweater, then place it at 32°C for 26 hours, dry at 30°C, and set aside;

[0024] b. Organize:

[0025] Finishing solution: configured according to the following mass percentages, select 60g / L of phosphorus-containing polymaleic acid with a viscosity-average molecular weight of 172, 38g / L of sodium hypophosphite, and 0.8g / L of polyoxyethylene fatty acid ester;

[0026] The finishing process is as follows: put the pretreated woolen sweater in the finishing solution, according to the bath ra...

Embodiment 2

[0028] The use of antibacterial finishing additives for woolen sweaters:

[0029] (1) Select high-quality wool fibers and weave them into garments;

[0030] (2) Finishing:

[0031] a. Preprocessing:

[0032] Pretreatment protein solution: according to mass percentage, hydrolyzed feather powder 0.09%, corn gluten powder 0.02%, trehalose 1.1%;

[0033] Pretreatment: Spray the pretreated protein solution evenly on the woolen sweater, the spraying weight is 0.2 times the weight of the woolen sweater, then place it at 28°C for 31 hours, dry it at 30°C, and set aside;

[0034] b. Organize:

[0035] Finishing solution: configured according to the following mass percentages, select 81g / L of phosphorus-containing polymaleic acid with a viscosity-average molecular weight of 169, 32g / L of sodium hypophosphite, and 0.8g / L of polyoxyethylene fatty acid ester;

[0036] The finishing process is as follows: put the pretreated woolen sweater in the finishing solution, according to the bath...

Embodiment 3

[0038] The use of antibacterial finishing additives for woolen sweaters:

[0039] (1) Select high-quality wool fibers and weave them into garments;

[0040] (2) Finishing:

[0041] a. Preprocessing:

[0042] Pretreatment protein solution: according to mass percentage, hydrolyzed feather powder 0.06%, corn gluten powder 0.04%, trehalose 0.6%;

[0043] Pretreatment: Spray the pretreated protein solution evenly on the woolen sweater, the spraying weight is 0.2 times the weight of the woolen sweater, then place it at 31°C for 27 hours, dry at 30°C, and set aside;

[0044] b. Organize:

[0045] Finishing solution: configured according to the following mass percentages, select 70g / L of phosphorus-containing polymaleic acid with a viscosity-average molecular mass of 171, 37g / L of sodium hypophosphite, and 0.8g / L of polyoxyethylene fatty acid ester;

[0046] The finishing process is as follows: put the pretreated woolen sweater in the finishing solution, according to the bath rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com