a kind of mosi 2 -sic-cu conductance composite ceramic material and preparation method thereof

A composite ceramic, mosi2-sic-cu technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of poor comprehensive performance of SiC-Cu composite materials, and improve low-temperature and high-temperature mechanical properties, good thermal conductivity and mechanical properties. , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

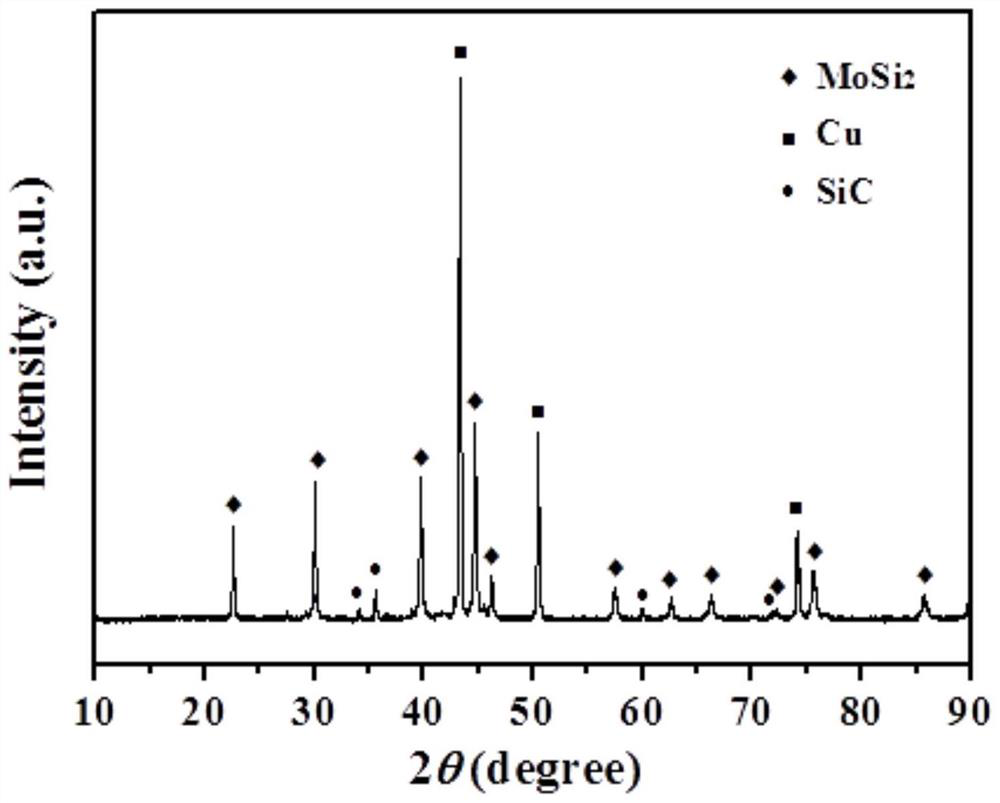

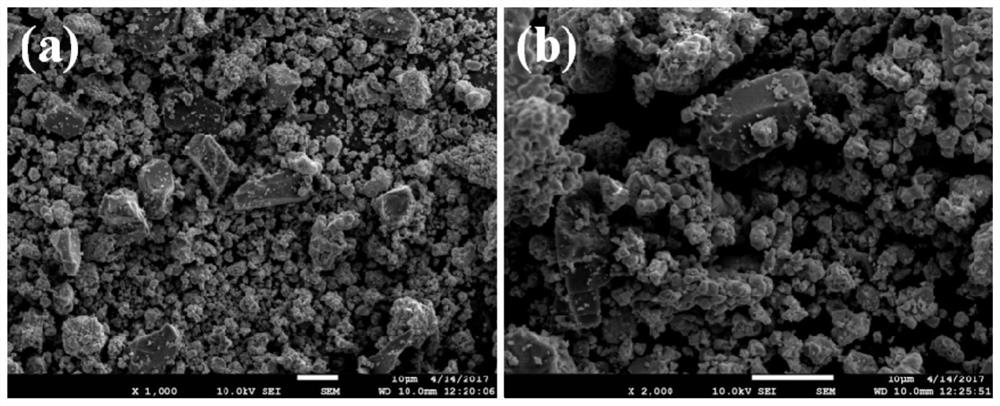

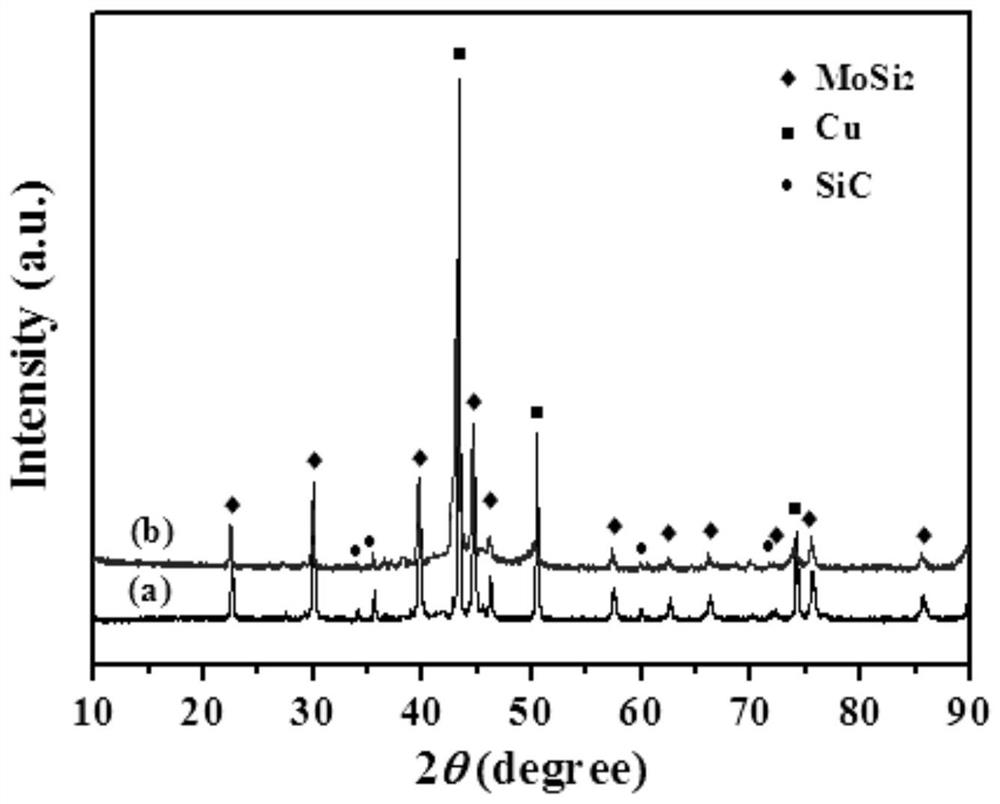

[0034] MoSi in this example 2-SiC-Cu conductive composite ceramic material, composed of the following components in volume percentage: SiC10%, the balance is MoSi 2 and Cu; MoSi 2 The volume ratio of Cu and Cu is 1:2.

[0035] MoSi in this example 2 -The preparation method of SiC-Cu conductance composite ceramic material, comprises the following steps:

[0036] 1) Take the amount of MoSi in the formula 2 Powder, SiC powder and Cu powder are mixed and passed through a 200-mesh sieve for 5 times, and then ground evenly to obtain MoSi 2 -SiC-Cu composite powder; MoSi 2 The particle size of the powder is 3 μm; the particle size of the SiC powder is 10 μm; the particle size of the Cu powder is 48 μm;

[0037] 2) the MoSi obtained in step 1) 2 - SiC-Cu composite powder is poured into a graphite mold, the graphite mold is put into a vacuum hot-pressing sintering furnace, vacuumized, pre-pressed at room temperature and 30MPa for 5 minutes, and the pressure is released to obtain...

Embodiment 2

[0041] MoSi in this example 2 -SiC-Cu conductive composite ceramic material, composed of the following components in volume percentage: SiC10%, the balance is MoSi 2 and Cu; MoSi 2 The volume ratio to Cu is 1:1.5.

[0042] MoSi in this example 2 -The preparation method of SiC-Cu conductance composite ceramic material, comprises the following steps:

[0043] 1) Take the amount of MoSi in the formula 2 Powder, SiC powder and Cu powder are mixed and passed through a 200-mesh sieve for 5 times, and then ground evenly to obtain MoSi 2 -SiC-Cu composite powder; MoSi 2 The particle size of the powder is 3 μm; the particle size of the SiC powder is 10 μm; the particle size of the Cu powder is 48 μm;

[0044] 2) the MoSi obtained in step 1) 2 - SiC-Cu composite powder is poured into a graphite mold, the graphite mold is put into a vacuum hot-pressing sintering furnace, vacuumized, pre-pressed at room temperature and 30MPa for 5 minutes, and the pressure is released to obtain a g...

Embodiment 3

[0047] MoSi in this example 2 - SiC-Cu conductive composite ceramic material, composed of the following components in volume percentage: SiC30%, the balance is MoSi 2 and Cu; MoSi 2 The volume ratio of Cu and Cu is 1:1.

[0048] MoSi in this example 2 -The preparation method of SiC-Cu conductance composite ceramic material, comprises the following steps:

[0049] 1) Take the amount of MoSi in the formula 2 SiC powder, SiC powder and Cu powder are mixed and passed through a 200-mesh sieve for 3 times, and then ground evenly to obtain MoSi 2 -SiC-Cu composite powder; MoSi 2 The particle size of SiC powder is 1 μm; the particle size of SiC powder is 8 μm; the particle size of Cu powder is 40 μm;

[0050] 2) the MoSi obtained in step 1) 2 - SiC-Cu composite powder is poured into a graphite mold, the graphite mold is put into a vacuum hot-pressing sintering furnace, vacuumized, pre-pressed at room temperature and 40MPa for 8 minutes, and the pressure is released to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com