Redispersible powder composition for dry mortar formulations

A composition and formulation technology, applied in the field of preparing dry mortar formulations, prolonging the drying time of dry mortar formulations, and redispersible powder compositions, can solve problems such as loss of binding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method of preparing the modified dry mortar formulation. The preparation method comprises the following steps: a) providing a standard dry mortar formulation, b) mixing the modifier composition detailed above with the standard dry mortar formulation, wherein the compound of the modifier composition Can be mixed with said standard dry mortar formulations independently or in combination. Preferably, based on the weight of the modified dry mortar formulation, the content of the modifier composition is 0.3-40%, preferably 0.4-30%, more preferably 0.5-15%.

[0050]When preparing the modified dry mortar formulations of the present invention, the relative amounts of essential and optional compounds in the modifier composition should be adapted to the total amount required for the final modified dry mortar formulation. As known to those skilled in the art, the modifier compositions can be prepared with appropriate amounts of required and o...

Embodiment

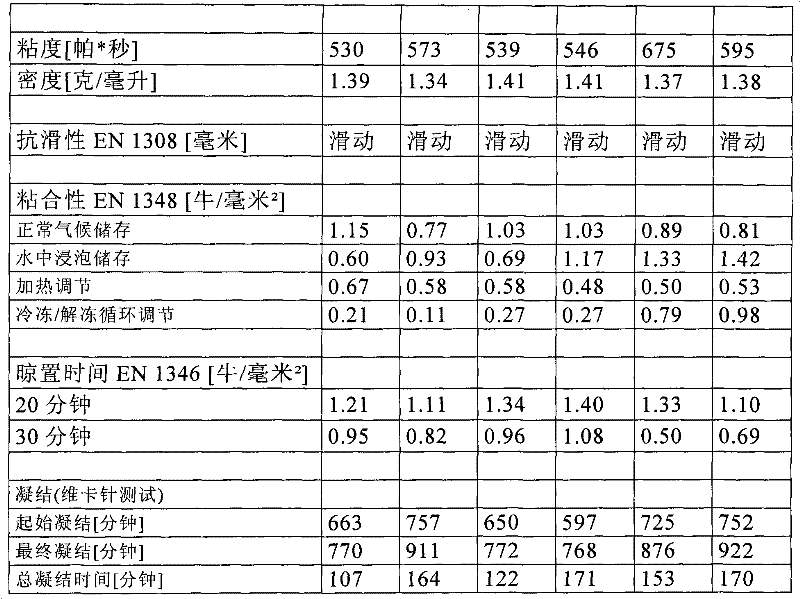

[0063] The performance of the cementitious tile adhesives of the present invention was investigated by comparing various formulations in dry mortar with and without superplasticizer without changing the water-solids ratio.

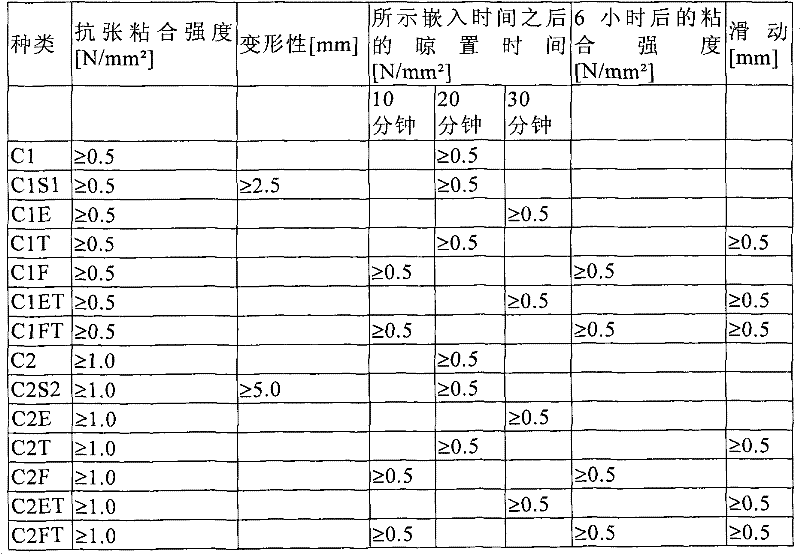

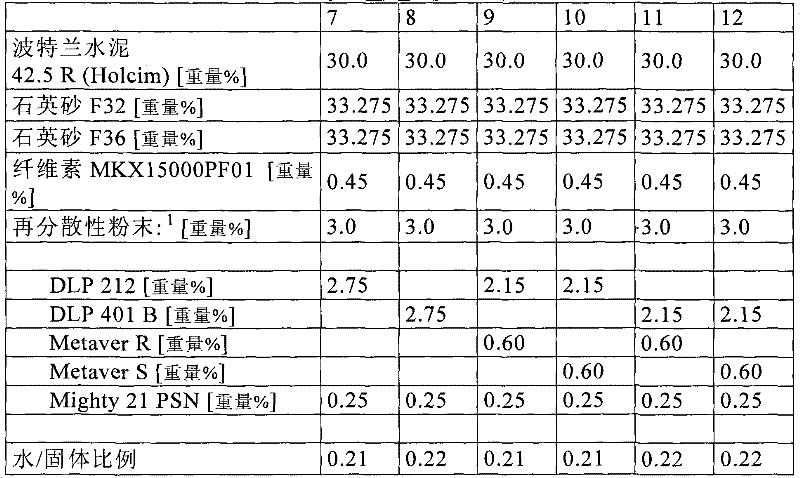

[0064] In Tables 2 and 3, the tested formulations as reference as well as the formulations of the invention are listed. No. 1-6 formulations (Table 2) are used as reference, and No. 7-12 formulations (Table 3) are formulations of the present invention.

[0065] All formulations contain the following components as a base: 30% by weight of Ordinary Portland cement CEM 1 42.5R (Holcim, Germany), 33.275% by weight of siliceous sand F32 (Kurz, Germany) Microgram Furuike (Quarzwerke Frechen, Germany)), 33.275% by weight of siliceous sand F 36 (Germany's Kozwerke Frechen (Quarzwerke Frechen, Germany)) and 0.45% by weight of Walocel MKX 15000PF01 (hydroxyethyl methyl Cellulose based, Dow Wolff Cellulosics, Germany). Additionally, all formulations contained 3% by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com