Catalyst for preparing ethylene glycol through dimethyl oxalate gas phase hydrogenation, and preparation method and application thereof

A dimethyl oxalate and catalyst technology, which is applied in the field of preparation of ethylene glycol catalysts by hydrogenation of dimethyl oxalate, can solve the problems of easy loss of active components, inability to exert activity, and easy coking, etc., and achieve the suppression of impurity products The formation, stable bed temperature, and high space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

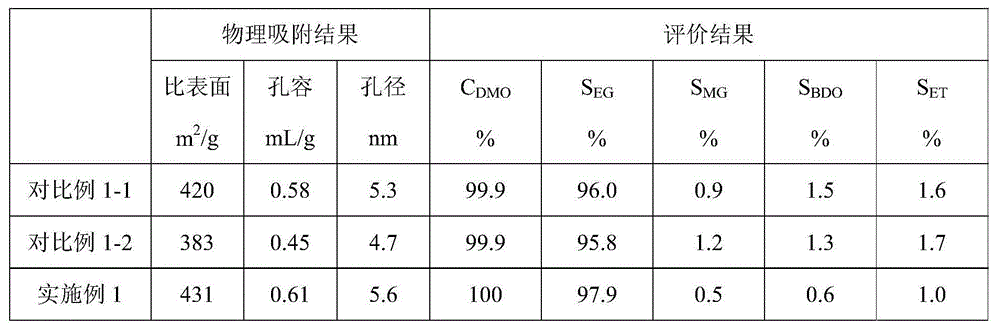

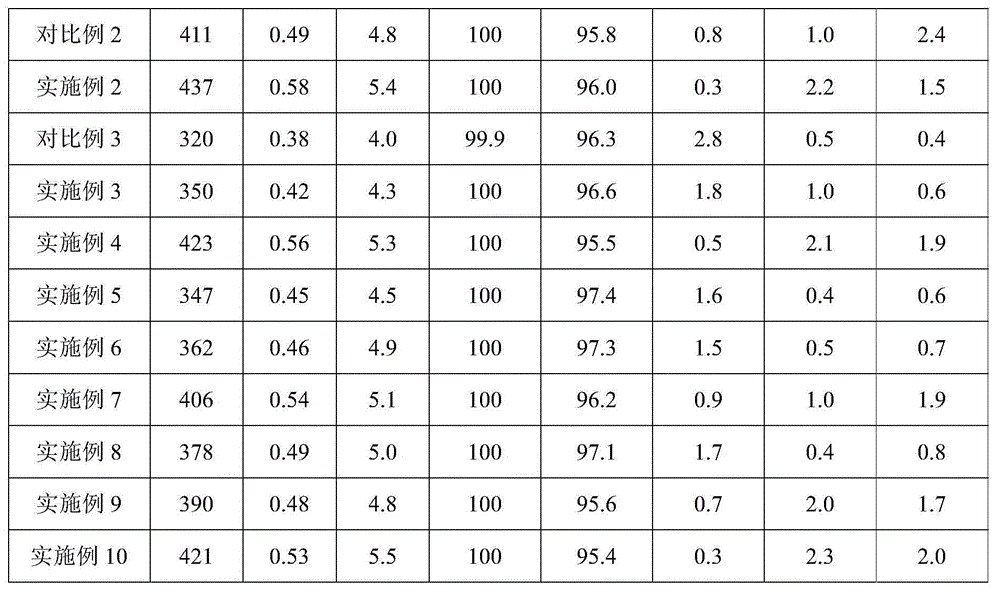

Examples

Embodiment 1

[0047] Preparation of dimethyl oxalate gas-phase hydrogenation to produce ethylene glycol catalyst, the composition is CuO48wt%, SiO 2 50wt% and NiO2.0wt%; the preparation process is as follows:

[0048] Weigh SiO first 2 Add 5.0Kg of silica sol with a content of 25%, add 4.8Kg of deionized water, mix well, weigh 2.7Kg of urea to dissolve in it, mix well, and adjust the pH to 6.0 with concentrated nitric acid. 9.6Kg of copper nitrate solution of 10.0wt% Cu was weighed again, and 194g of solid nickel nitrate was weighed and dissolved in the copper nitrate solution. Then the two solutions were mixed evenly and poured into the reactor together. The reaction kettle was heated with a water bath, the reaction temperature was raised to 95° C., the stirring speed was adjusted to 300 rpm, and the reflux condensation was performed for 10 hours. The suspension after the reaction was taken out, filtered with a filter press, and the filtered cake was washed with deionized water until th...

Embodiment 2

[0051] Preparation of dimethyl oxalate gas-phase hydrogenation to produce ethylene glycol catalyst, the composition is CuO20wt%, SiO 2 79wt% and Na 2 O1.0wt%; The preparation process is as follows:

[0052] Weigh SiO first 2 Add 6.6Kg of silica sol with a content of 30%, add 9.3Kg of deionized water, mix well, weigh 1.2Kg of urea to dissolve in it, mix well, and adjust the pH to 1.0 with concentrated nitric acid. 5.0Kg of 8.0wt% Cu copper nitrate solution was weighed again, and 34.3g of solid sodium nitrate was weighed and dissolved in the copper nitrate solution. Then the two solutions were mixed evenly and poured into the reactor together. The reaction kettle was heated with a water bath, the reaction temperature was raised to 85° C., the stirring speed was adjusted to 300 rpm, and reflux condensed for 26 hours. The suspension after the reaction was taken out, filtered with a filter press, and the filtered cake was washed with deionized water until the washing liquid was...

Embodiment 3

[0055] Preparation of dimethyl oxalate gas-phase hydrogenation to produce ethylene glycol catalyst, the composition is CuO70wt%, SiO 2 25wt% and ZnO5.0wt%; the preparation process is as follows:

[0056] Weigh SiO first 2 Add 2.5Kg of silica sol with a content of 25%, add 4.5Kg of deionized water, mix well, weigh 3.9Kg of urea, dissolve in it, mix well, and adjust the pH to 3.0 with concentrated nitric acid. 11.1Kg of copper nitrate solution of 12.6wt% Cu was weighed again, and 458g of solid zinc nitrate was weighed and dissolved in the copper nitrate solution. Then the two solutions were mixed evenly and poured into the reactor together. The reaction kettle was heated with a water bath, the reaction temperature was raised to 75° C., the stirring speed was adjusted to 300 rpm, and the reflux condensation was performed for 35 hours. The suspension after the reaction was taken out, filtered with a filter press, and the filtered cake was washed with deionized water until the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com