Wear-resistant low floating fiber glass fiber enhanced polyphenylene sulfide free-spraying composite material and preparation method thereof

A technology of polyphenylene sulfide and floating fiber glass fiber, which is applied in the field of polymer material modification, can solve the problems of difficulty in meeting the requirements for appearance and precision parts, large amount of wear-resistant agent, and application expansion limitations, and achieves the appearance effect. Shiny effects, great design freedom, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

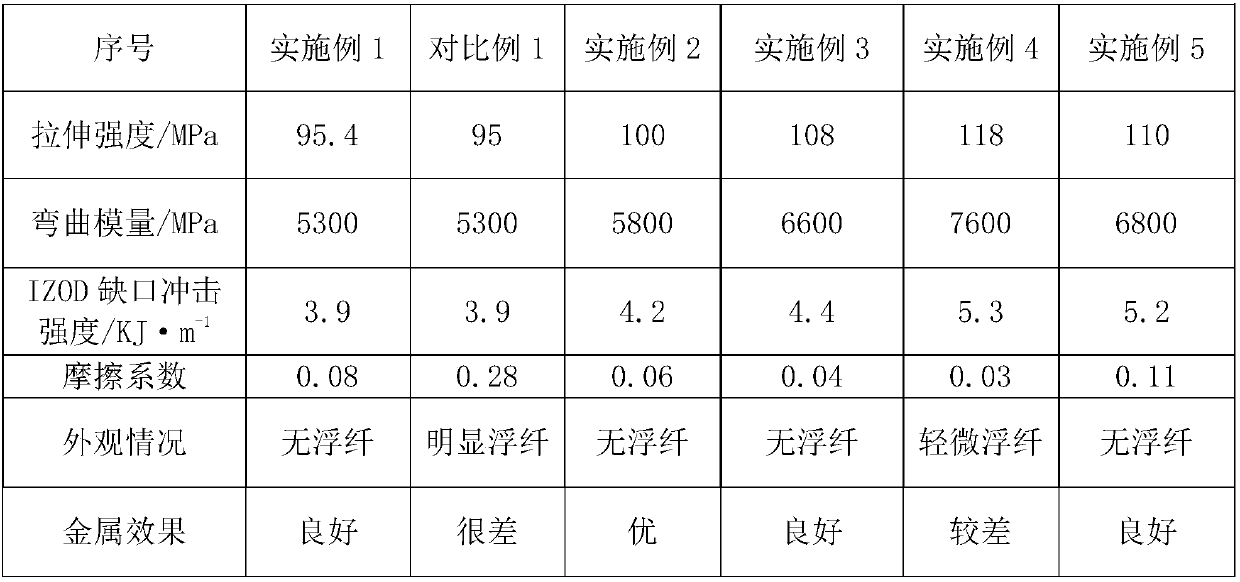

Examples

Embodiment 1

[0046] Example 1 Preparation of wear-resistant and low-floating fiber glass fiber reinforced polyphenylene sulfide spray-free composite material

[0047] (1) Preparation of wear-resistant and anti-floating fiber masterbatch

[0048] Take 73 parts by weight of polyphenylene sulfide 1150C, 15 parts of molybdenum disulfide, 10 parts of graphite, 1 part of aluminum powder, 0.2 parts of antioxidant 168, 0.2 parts of light stabilizer V703, compatibilizer EMA-g-MAH 0.3 parts, 0.3 parts of lubricant EBS, the aluminum powder adopts silver dollar-shaped aluminum powder with a diameter of 20-30 μm; mix the above materials evenly in a high-speed mixer, and then melt and extrude the mixture through a twin-screw extruder, Finally, cool and dry to obtain wear-resistant and anti-floating fiber masterbatch. The processing temperature from the first zone to the ninth zone is 200°C, 260°C, 270°C, 280°C, 280°C, 285°C, 285°C, 290°C, 290°C, the speed is 280r / min, and the feeding speed is 20r / min. ...

Embodiment 2

[0053] Example 2 Preparation of wear-resistant and low-floating fiber glass fiber reinforced polyphenylene sulfide spray-free composite material

[0054] (1) Preparation of wear-resistant and anti-floating fiber masterbatch

[0055] Take 64 parts by weight of polyphenylene sulfide 1170C, 16.5 parts of molybdenum disulfide, 17 parts of graphite, 1 part of aluminum powder, 0.4 part of antioxidant 412s, 0.3 part of antioxidant 168, compatibilizer EMA-g-MAH 0.5 parts, lubricant EBS 0.3 parts, the aluminum powder adopts silver dollar-shaped aluminum powder with a diameter of 20-30 μm; mix the above materials evenly in a high-speed mixer, and then melt and extrude the mixture through a twin-screw extruder, Finally, cool and dry to obtain wear-resistant and anti-floating fiber masterbatch. The processing temperature from the first zone to the ninth zone is 200°C, 260°C, 270°C, 280°C, 280°C, 285°C, 285°C, 290°C, 290°C, the speed is 280r / min, and the feeding speed is 20r / min. min.

...

Embodiment 3

[0058] Example 3 Preparation of wear-resistant and low-floating fiber glass fiber reinforced polyphenylene sulfide spray-free composite material

[0059] (1) Preparation of wear-resistant and anti-floating fiber masterbatch

[0060] Take 59 parts by weight of PPS1190C, 20 parts of molybdenum disulfide, 18 parts of graphite, 1 part of aluminum powder, 1680.5 parts of antioxidant, 0.4 part of antioxidant 1010, 0.6 part of compatibilizer EMA-g-MAH, lubricant 0.5 part of EBS, the aluminum powder adopts silver dollar-shaped aluminum powder with a diameter of 20-30 μm; the above materials are mixed uniformly in a high-speed mixer, and then the mixture is melted and extruded by a twin-screw extruder, and finally cooled and dried. Obtain wear-resistant and anti-floating fiber masterbatch. The processing temperature from the first zone to the ninth zone is 200°C, 260°C, 270°C, 280°C, 280°C, 285°C, 285°C, 290°C, 290°C, the speed is 280r / min, and the feeding speed is 20r / min. min.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com