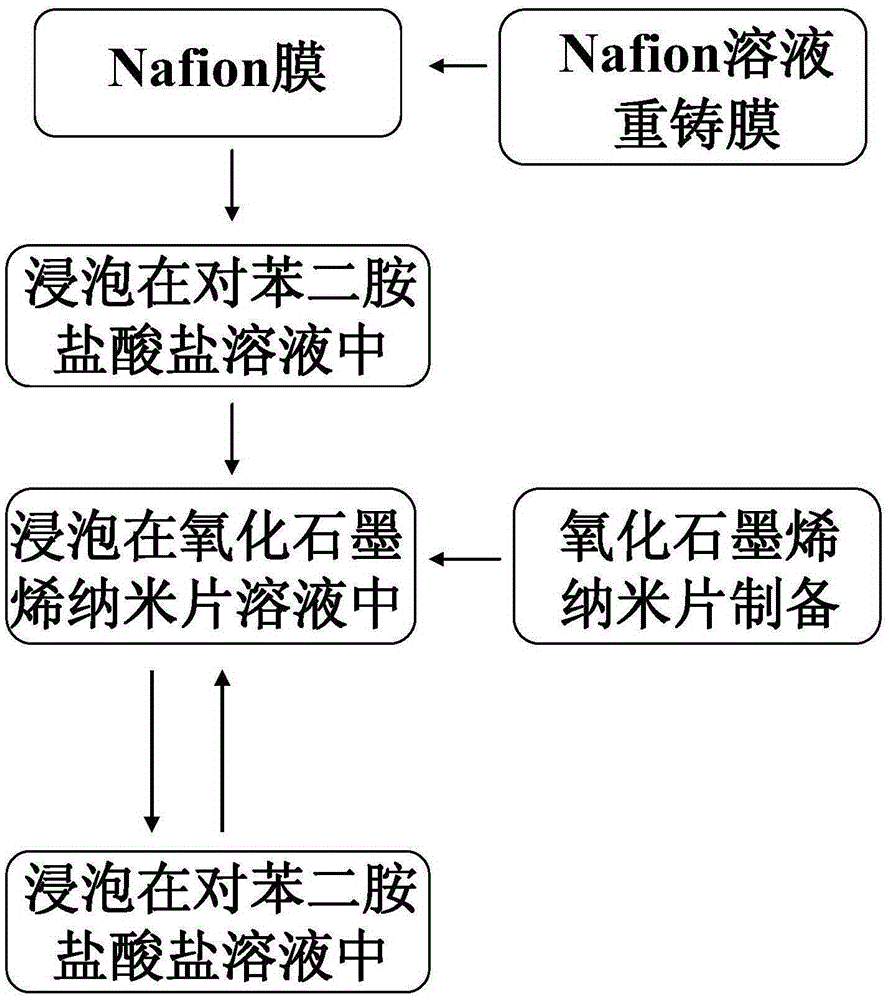

A kind of preparation method of composite proton exchange membrane

A proton exchange membrane and solution technology, which is applied in the field of composite proton exchange membrane preparation, can solve the problems affecting the proton conductivity of composite membranes, graphene oxide is easy to agglomerate, and the water content of the membrane is reduced, so as to achieve low methanol methanol permeability and easy Obtaining the effect of reducing the permeability of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

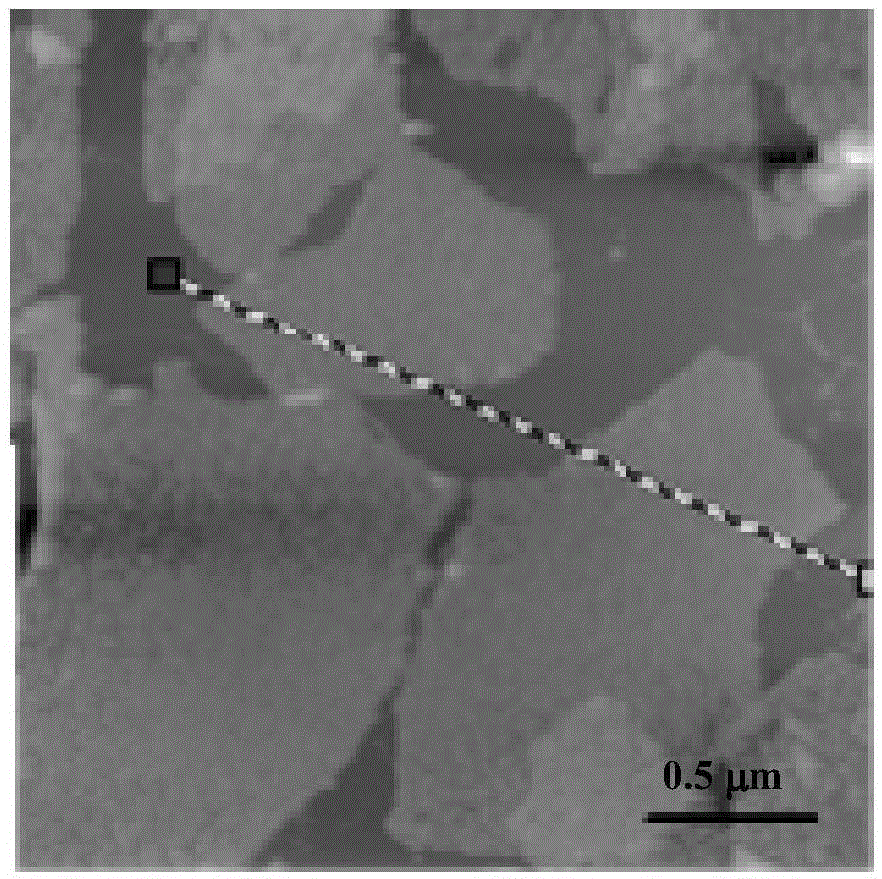

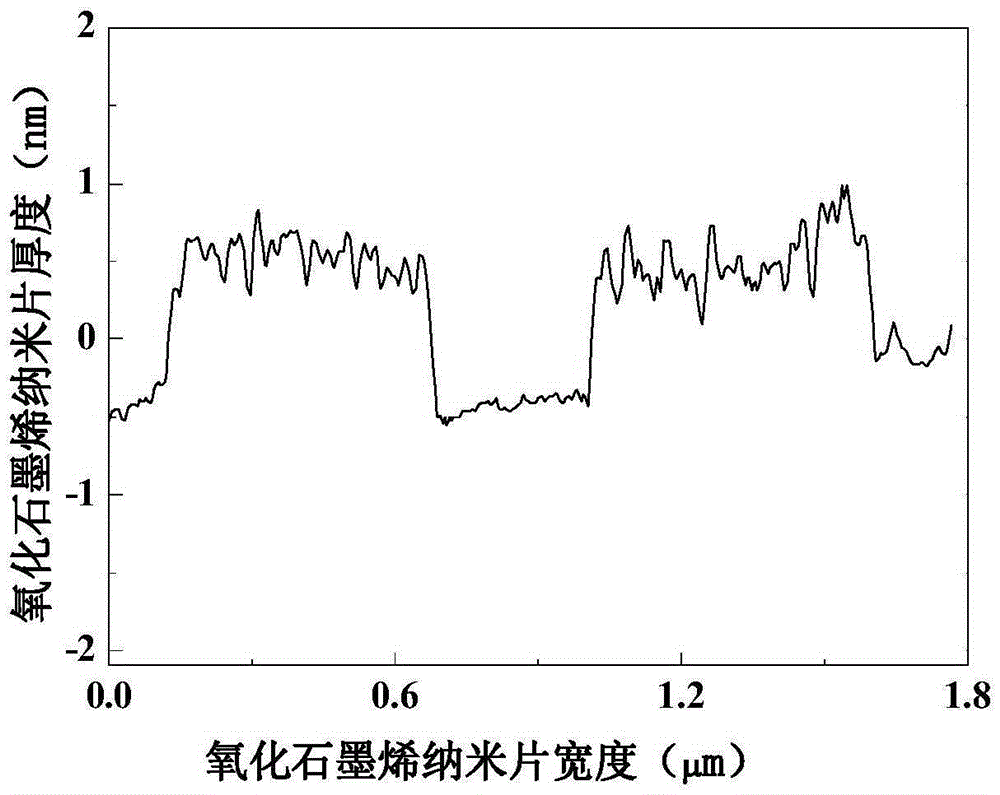

[0033] Firstly, graphene oxide is prepared. Add 2g of graphite powder, 1g of sodium nitrate, and 46mL of concentrated sulfuric acid into a 500mL round-bottomed flask, place it in an ice bath to 0°C and keep stirring for 1 hour, remove the ice bath, then slowly add 6g of potassium permanganate while vigorously stirring, and control the temperature to a low temperature Keep at 20°C and 35°C for 1h, then add 92mL of deionized water dropwise, keep stirring at 95°C for 2h, then add 280mL of deionized water, and 40mL of 30% hydrogen peroxide solution to neutralize potassium permanganate, Centrifuge and wash the obtained product at a speed of 6000rpm, wash once with 5% dilute hydrochloric acid, wash three times with water, and finally dry the product under vacuum at 70°C for 24 hours, weigh the quality of the product obtained, and disperse the product in deionized water to obtain 2.8wt % graphene oxide aqueous solution, and ultrasonic 4h, obtain graphene oxide nanosheet solution.

...

Embodiment 2

[0037] The preparation of graphene oxide and The recasting of the 117 film was the same as in Example 1. When preparing the composite film, first prepare the assembly solution, take 525 μL of 2.8wt% graphene oxide nanosheet solution and 70 mL deionized water, and prepare a 1 mg / 5mL graphene oxide nanosheet solution, which is dispersed evenly by ultrasonic; 0.3516 g of p-diphenylamine The hydrochloride was added to 70 mL of deionized water to prepare a 0.5 wt % p-diphenylamine solution. will be preprocessed The 117 membrane is alternately placed in p-diphenylamine solution and 1mg / 5mL graphene oxide nanosheet solution for self-assembly process, each soaking in diphenylamine solution and 1mg / 5mL graphene oxide nanosheet solution is one assembly, continuous Complete 30 assemblies. The assembly time of the 117 membrane in each assembly solution should be more than 1.5h to ensure that the graphene oxide nanosheets and p-diphenylamine can be stably assembled on the membrane surf...

Embodiment 3

[0039] The preparation of graphene oxide and The recasting of the 117 film was the same as in Example 1. When preparing the composite film, first prepare the assembly solution, take 525 μL of 2.8wt% graphene oxide nanosheet solution and 70 mL deionized water, and prepare a 1 mg / 5mL graphene oxide nanosheet solution, which is dispersed evenly by ultrasonic; 0.3516 g of p-diphenylamine The hydrochloride was added to 70 mL of deionized water to prepare a 0.5 wt % p-diphenylamine solution. will be preprocessed The 117 membrane is alternately placed in p-diphenylamine solution and 1mg / 5mL graphene oxide nanosheet solution for self-assembly process, each soaking in diphenylamine solution and 1mg / 5mL graphene oxide nanosheet solution is one assembly, continuous Complete 50 assemblies. The assembly time of the 117 membrane in each assembly solution should be more than 1.5h to ensure that the graphene oxide nanosheets and p-diphenylamine can be stably assembled on the membrane su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com