Flotation column

A flotation column and column technology, applied in flotation, solid separation, etc., can solve the problems that the gas cannot be uniformly dispersed, difficult to check and maintain, and affect the strength of the flotation column, so as to achieve easy inspection and maintenance, long service life, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

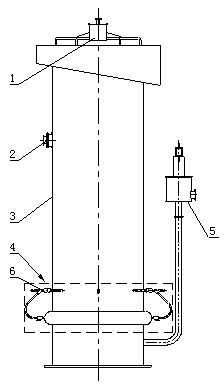

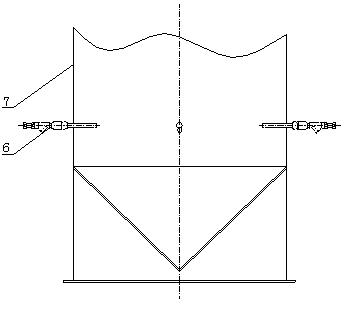

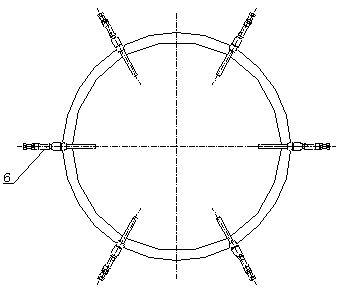

[0017] The flotation column of the present invention includes a spray water assembly, a ore supply system, a column assembly and a tailing system, and the flotation column also includes a flotation column cone bottom and a plurality of flotation column aerators (see Figure 4 ), the cone bottom 8 of the flotation column is located in the lower part of the flotation column, the cone bottom of the cone bottom 8 of the flotation column is downward in a funnel shape, and the upper edge is welded to the inner wall of the column assembly. The conical column bottom 8 of the flotation column provides ample space for the configuration of the flotation column aerator, ensuring that the aerator can be distributed in multiple circles at different heights in the space; and can promote the smooth discharge of the slurry in the flotation column to prevent Mineral particles pile up and sink.

[0018] Multiple flotation column aerators 7 are installed on the bottom of the conical column, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com