Blend optical film with thermodynamic stability and preparation method thereof

A thermodynamically stable, optical thin film technology, applied in the field of polymer materials, can solve problems such as limited compatibility, different refractive indices, and increased haze, and achieve excellent transparency, high photoelastic coefficient, and low surface hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

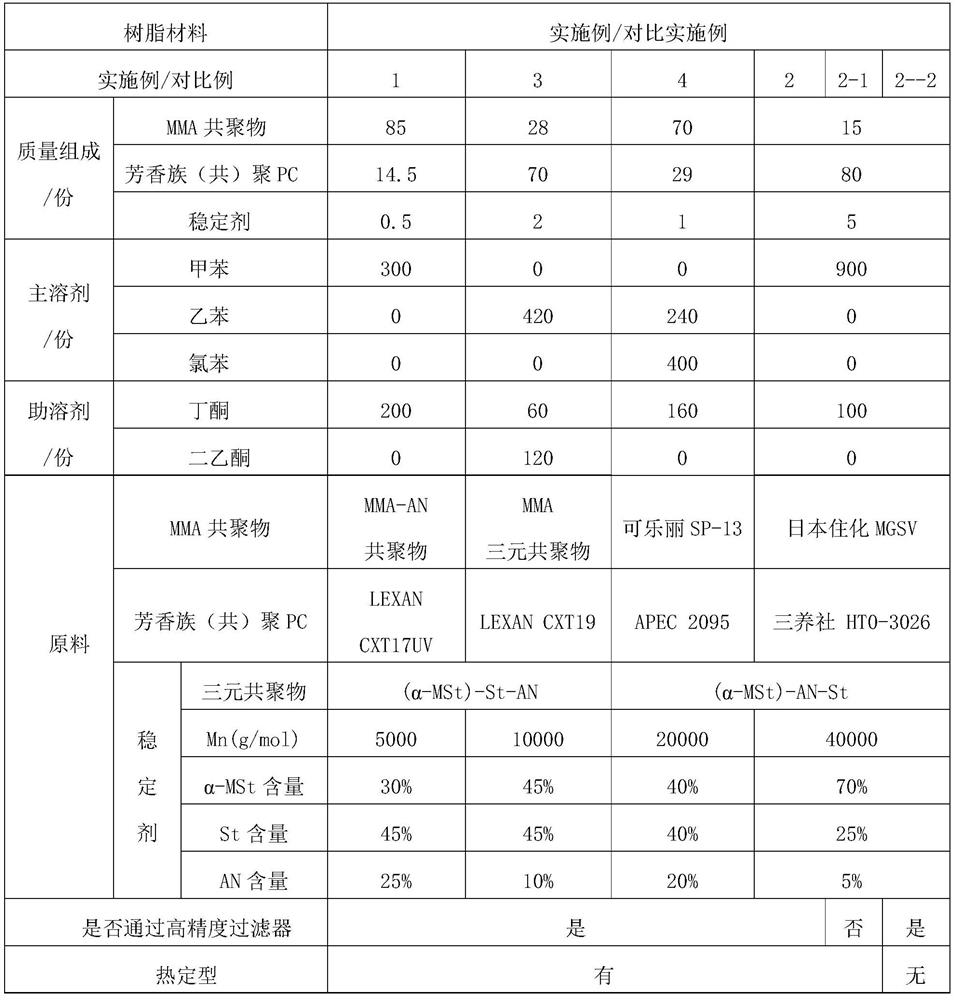

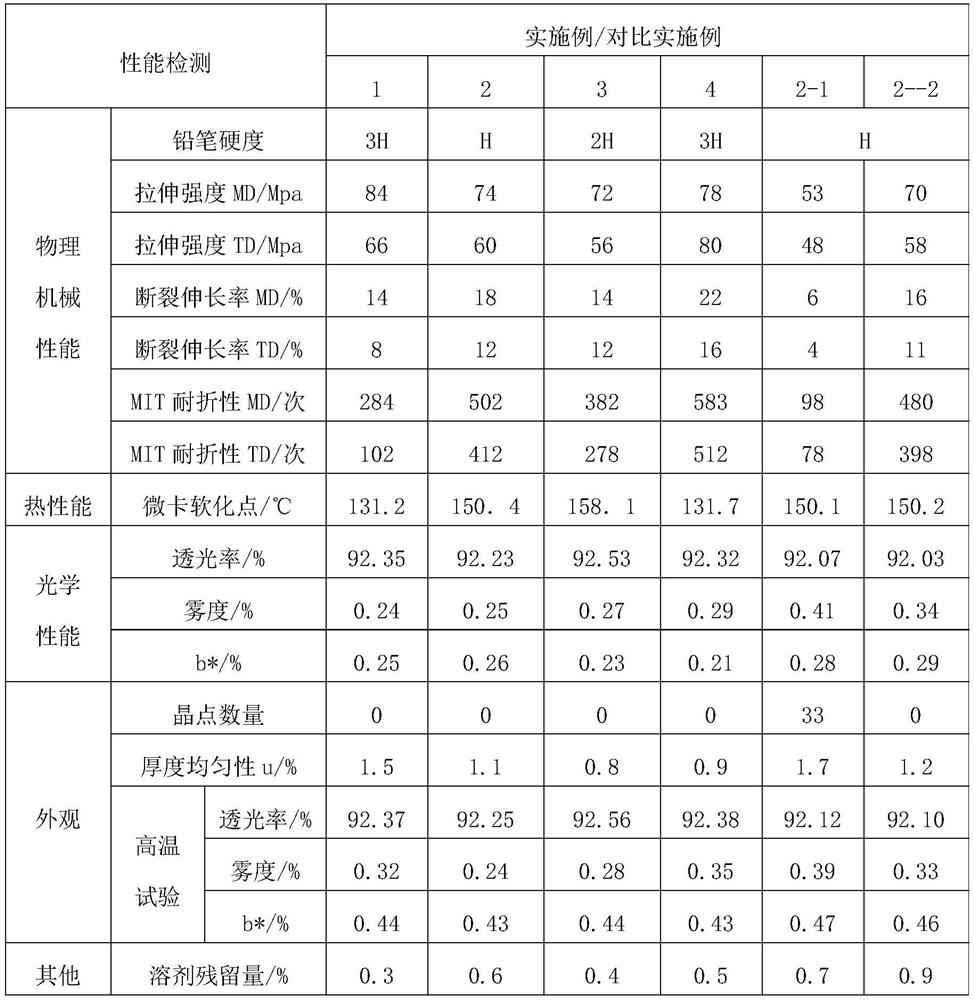

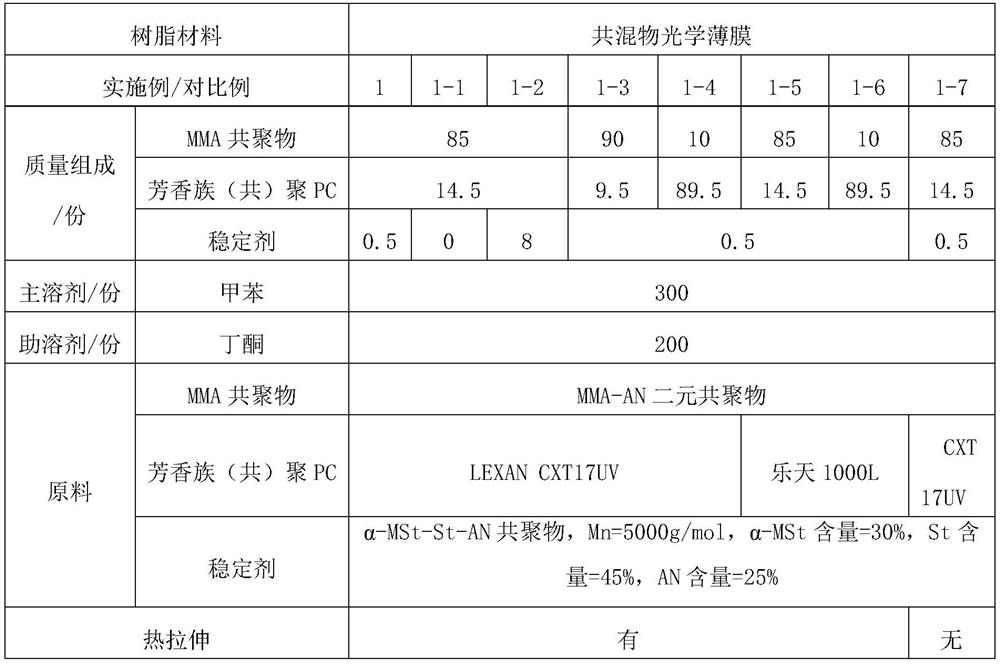

Examples

preparation example Construction

[0081] The present application also provides a method for preparing the thermodynamically stable blend optical film provided above, comprising the following steps:

[0082] (1) Pretreatment of raw materials

[0083] The methyl methacrylate polymer, the stabilizer and the aromatic polycarbonate are separately removed from the water and then used for subsequent use;

[0084] Dry the co-solvent for later use;

[0085] (2) Preparation and refining of coating solution

[0086] Weigh a certain proportion of processed methyl methacrylate polymer, aromatic polycarbonate, stabilizer and co-solvent;

[0087] Adding methyl methacrylate polymer, aromatic polycarbonate and stabilizer to the co-solvent several times, stirring and dissolving to obtain coating mother liquor;

[0088] Filter the coating mother liquor through a filter to obtain a refined coating solution;

[0089] (3) Coating film formation

[0090] Coating the refined coating solution on the substrate, peeling off from th...

Embodiment 1

[0119] Embodiment 1, the specific steps of the preparation method of the blend optical film with thermodynamic stability are:

[0120] (1) Pretreatment of raw materials

[0121] Dry the methyl methacrylate polymer and the stabilizer in a blast oven at 70°C for 4 to 8 hours to fully remove moisture and set aside.

[0122] Dry the aromatic (co)polycarbonate in a blast oven at 90°C for 4-8 hours to fully remove moisture, and set aside.

[0123] Dry glass instruments such as flasks in a blast oven at 70°C for 6 hours to fully remove moisture and set aside.

[0124] The co-solvents were dried using molecular sieves, and then distilled under reduced pressure to obtain the middle distillate. Among them, co-solvents are analytically pure reagents.

[0125] (2) Preparation and refining of coating solution

[0126] Accurately weigh 85 parts of methyl methacrylate (MMA) polymer, 14.5 parts of aromatic (co)polycarbonate, 0.5 parts of stabilizer, and 500 parts of co-solvent.

[0127] ...

Embodiment 2

[0154] Embodiment 2, the specific steps of the preparation method of the blend optical film with thermodynamic stability are:

[0155] (1) Pretreatment of raw materials

[0156] Dry the methyl methacrylate polymer and the stabilizer in a blast oven at 100°C for 4 hours to fully remove moisture, and set aside.

[0157] Dry the aromatic (co)polycarbonate in a blast oven at 120°C for 4 hours to fully remove moisture, and set aside.

[0158] Dry glass instruments such as flasks in a blast oven at 100°C for 2 hours to fully remove moisture and set aside.

[0159] The co-solvents were dried using molecular sieves, and then distilled under reduced pressure to obtain the middle distillate. Among them, co-solvents are analytically pure reagents.

[0160] (2) Preparation and refining of coating solution

[0161] Accurately weigh 15 parts of methyl methacrylate (MMA) polymer, 80 parts of aromatic (co)polycarbonate, 5 parts of stabilizer, and 1000 parts of co-solvent.

[0162]Add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com