Surface-modified high-activity low-temperature denitration active coke and preparation method thereof

A surface modification, nitrate-activated coke technology, applied in catalyst activation/preparation, separation methods, chemical instruments and methods, etc., can solve problems such as low nitrogen oxide removal rate, achieve low-temperature denitrification, and improve denitrification reaction efficiency. , the effect of high denitration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

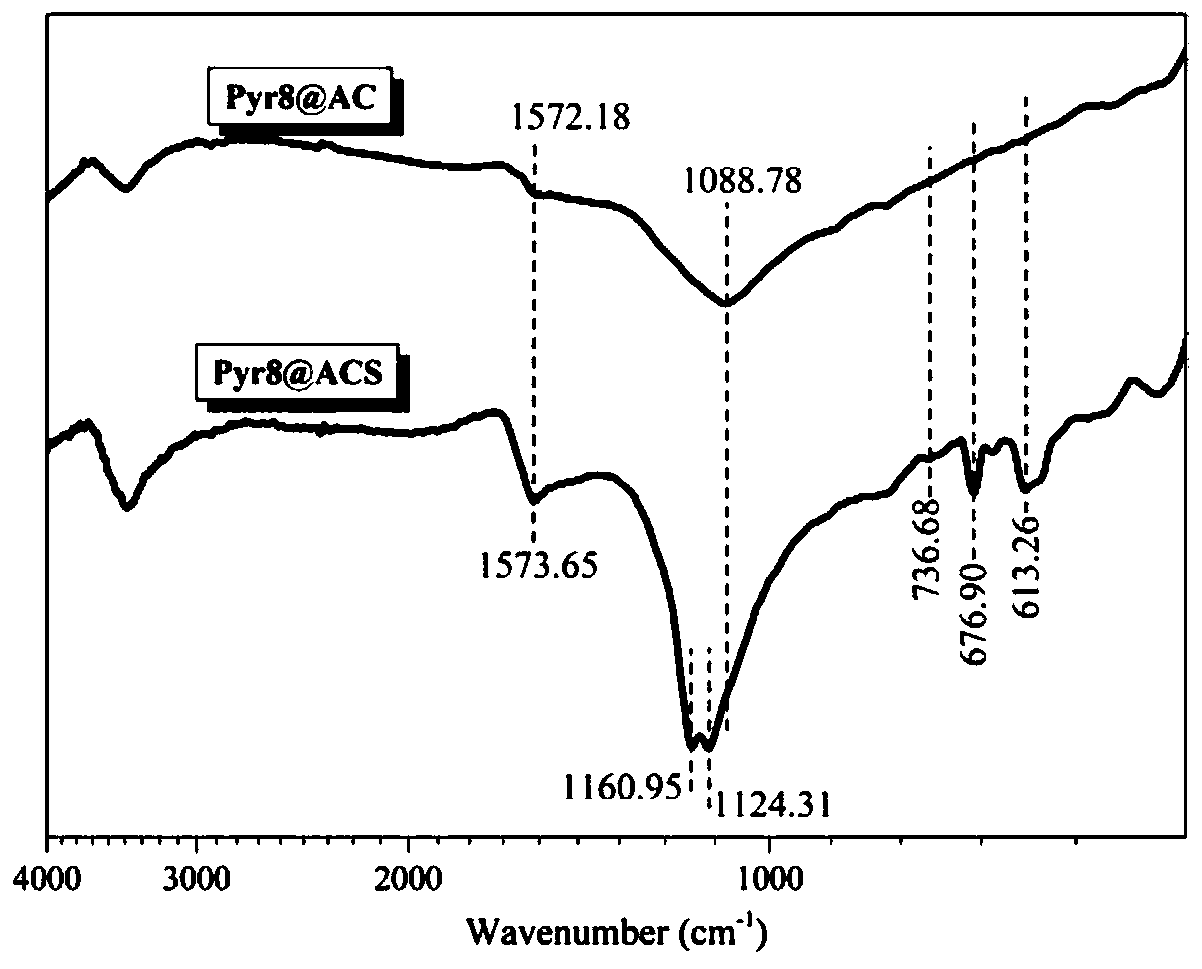

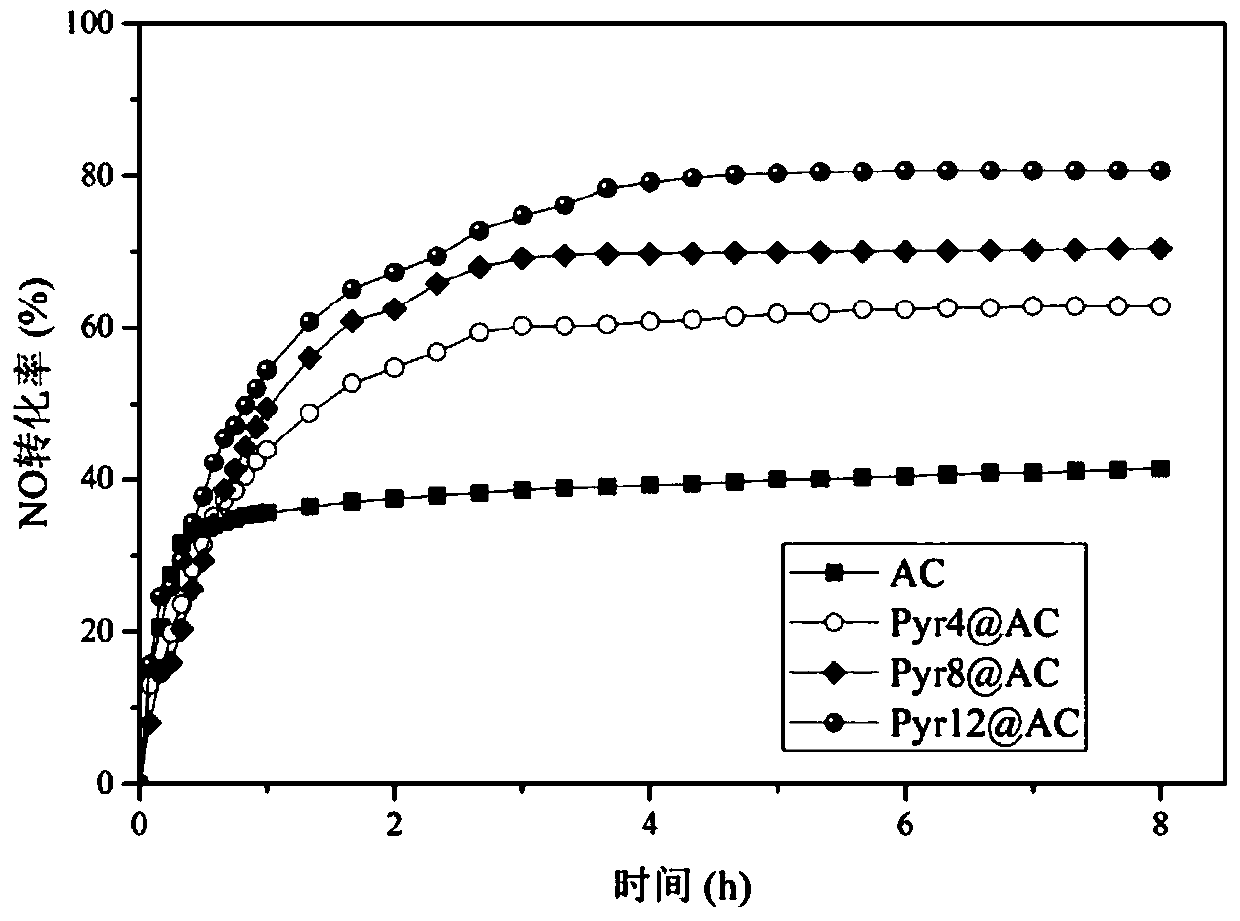

[0035] In this example, a series of surface-modified high-activity low-temperature denitrification active cokes with different additions of pyrolusite powder were prepared, and the steps were as follows:

[0036] (1) Bituminous coal and anthracite are crushed respectively, pulverized and passed through a 100-mesh sieve to obtain bituminous coal powder and anthracite powder, and pyrolusite (mainly composed of MnO 2 , the manganese content is 36.7%) crushing, grinding and passing through a 100-mesh sieve to obtain pyrolusite powder.

[0037] Fully mix the bituminous coal powder and anthracite powder to obtain mixed coal powder, the mass percentages of bituminous coal and anthracite in the mixed coal powder are 70% and 30% respectively; fully mix the mixed coal powder and pyrolusite powder, and then add Water and coal tar are fully kneaded to obtain a mixture, the addition of water and coal tar is respectively 10% and 42% of the mass of mixed coal powder, and the resulting mixtur...

Embodiment 2

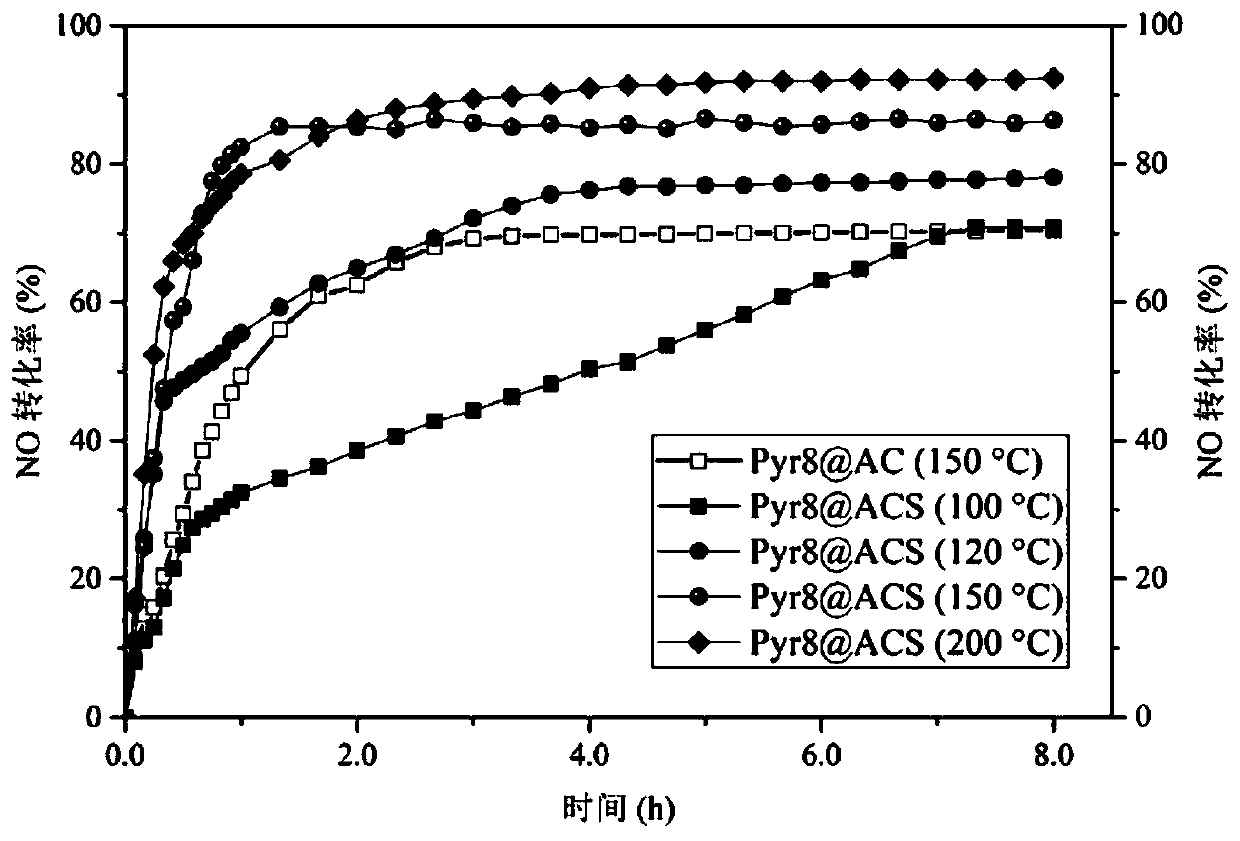

[0051] In this example, a series of surface-modified high-activity low-temperature denitrification activated cokes were prepared by impregnating equal volumes with dilute sulfuric acid of different concentrations. The steps are as follows:

[0052] (1) Bituminous coal and anthracite are crushed respectively, pulverized and passed through a 100-mesh sieve to obtain bituminous coal powder and anthracite powder, and pyrolusite (mainly composed of MnO 2 , the manganese content is 36.7%) crushing, grinding and passing through a 100-mesh sieve to obtain pyrolusite powder.

[0053] Fully mix the bituminous coal powder and anthracite powder to obtain mixed coal powder, the mass percentages of bituminous coal and anthracite in the mixed coal powder are 70% and 30% respectively; fully mix the mixed coal powder and pyrolusite powder, and then add Water and coal tar are fully kneaded to obtain a mixture, and the additions of pyrolusite powder, water and coal tar are respectively 8%, 10% a...

Embodiment 3

[0063] In this example, the preparation of surface-modified high-activity low-temperature denitrification activated coke is as follows:

[0064] (1) Bituminous coal and anthracite are crushed respectively, pulverized and passed through a 100-mesh sieve to obtain bituminous coal powder and anthracite powder, and manganese oxide ore (the main form of manganese has MnO 2 , Mn 2 o 3 and Mn 3 o 4 , with a total manganese content of 34.6%), crushed, pulverized and passed through a 100-mesh sieve to obtain manganese oxide ore powder.

[0065] Fully mix the bituminous coal powder and anthracite powder to obtain mixed coal powder, the mass percentages of bituminous coal and anthracite in the mixed coal powder are 70% and 30% respectively; fully mix the mixed coal powder and manganese oxide ore powder, and then add Water and coal tar are fully kneaded to obtain a mixture, and the additions of manganese oxide ore powder, water and coal tar are respectively 10%, 10% and 40% of the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com