Surface treatment method of silicon-doped calcium phosphate ceramics

A calcium-phosphorus ceramic and surface treatment technology, which is applied in the field of preparation of calcium-phosphorus ceramics, can solve problems such as complicated processing technology, and achieve the effects of simple process, improved adhesion, and improved osteoinductive ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

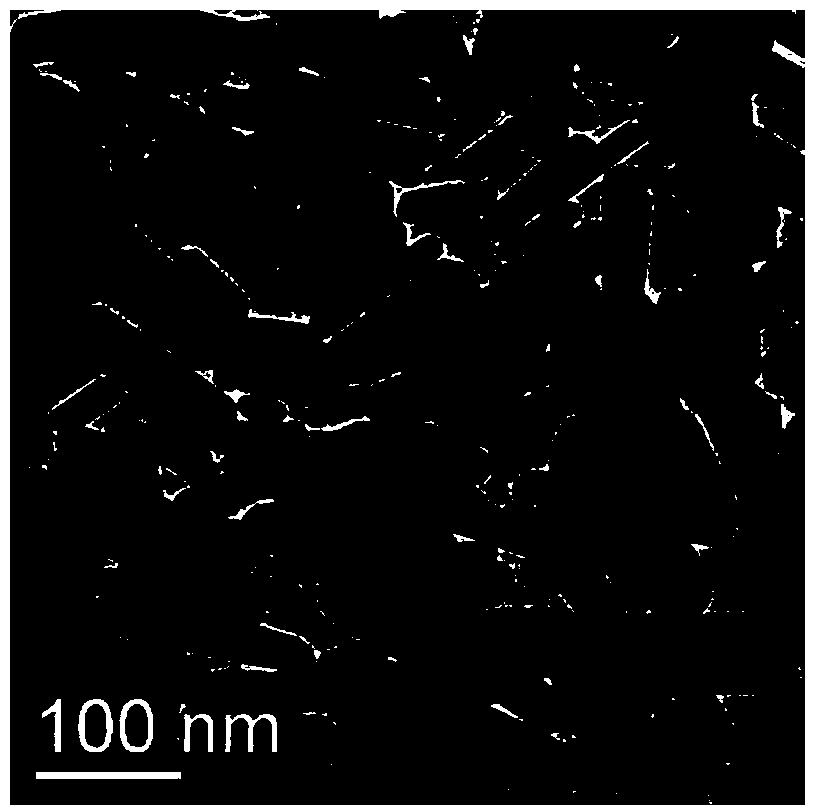

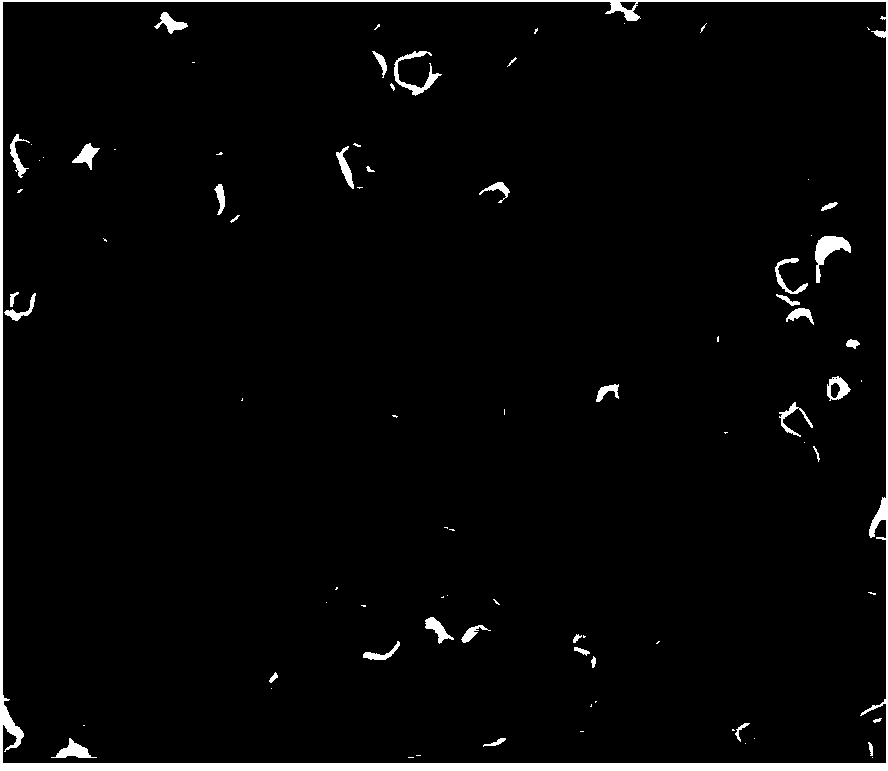

Image

Examples

Embodiment 1

[0038] The surface treatment method of the silicon-doped calcium-phosphorus ceramics (the silicon doping amount is 1.5wt%) of this embodiment includes the following steps:

[0039] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 solution and 0.25mol / L (NH 4 ) 3 PO 4 Solution, as calcium source and phosphorus source respectively, the consumption control Ca / (P+Si) mol ratio of adjusting calcium source and phosphorus source is 1.67; Regulate calcium source pH with ammonia water and be greater than 10, phosphorus source pH is greater than 9, and dispersing agent poly Ethylene glycol (6000) was added to the calcium source and stirred for 30 minutes, and tetraethyl orthosilicate was added to the phosphorus source and stirred for 30 minutes; then the phosphorus source was added dropwise to the calcium source, and after the addition was completed, continue to stir for 0.5 hours, and then transferred to the stainless steel Reaction kettle, heated at 160°C for 6 hours, centrifugally washed, dried ...

Embodiment 2

[0042] The surface treatment method of the silicon-doped calcium-phosphorus ceramics (the silicon doping amount is 2wt%) of this embodiment includes the following steps:

[0043] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 solution and 0.25mol / L (NH 4 ) 3 PO 4Solution, as calcium source and phosphorus source respectively, the consumption control Ca / (P+Si) mol ratio of adjusting calcium source and phosphorus source is 1.67; Regulate calcium source pH with ammonia water and be greater than 10, phosphorus source pH is greater than 9, and dispersing agent poly Add ethylene glycol (6000) to the calcium source and stir for 30 minutes, add tetraethyl orthosilicate to the phosphorus source and stir for 30 minutes; then add the phosphorus source to the calcium source drop by drop, continue stirring for 1 hour after the addition, and then transfer to stainless steel for reaction Kettle, heated at 200°C for 10 hours, centrifugally washed, dried overnight at 100°C, and ground to obtain nano-hydr...

Embodiment 3

[0046] The surface treatment method of the silicon-doped calcium-phosphorus ceramics (the silicon doping amount is 4wt%) of this embodiment includes the following steps:

[0047] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 solution and 0.25mol / L (NH 4 ) 3 PO 4 Solution, as calcium source and phosphorus source respectively, the consumption control Ca / (P+Si) mol ratio of adjusting calcium source and phosphorus source is 1.67; Regulate calcium source pH with ammonia water and be greater than 10, phosphorus source pH is greater than 9, and dispersing agent poly Add ethylene glycol (6000) to the calcium source and stir for 30 minutes, add tetraethyl orthosilicate to the phosphorus source and stir for 30 minutes; add the phosphorus source to the calcium source drop by drop, continue stirring for 1 hour after the dropwise addition, and then transfer to a stainless steel reaction kettle , heated at 180°C for 8 hours, centrifuged and washed, dried overnight at 70°C, and ground to obtain nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com