Three-dimensional printing porous bredigite biological ceramic bracket, and preparation method and application thereof

A technology of bioceramic and wonotlite, which is applied in the field of biomedical materials, can solve the problems of insufficient mechanical properties, limited application, poor pore connectivity of porous bone repair scaffold materials, etc., to achieve compact microstructure, promote bone tissue ingrowth, Enhanced bone regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

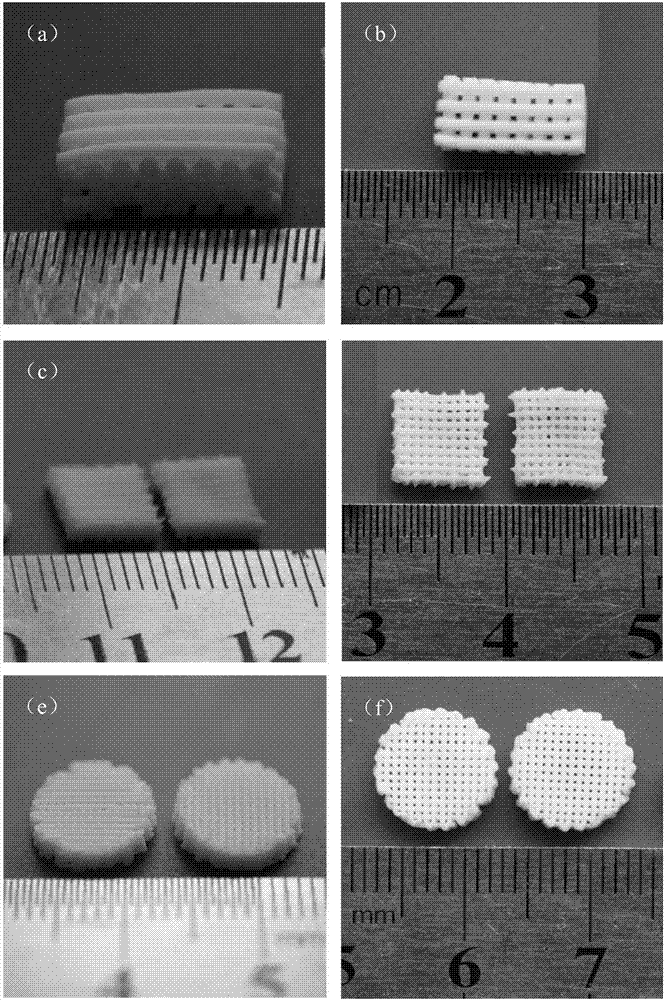

[0035] Embodiment 1, the preparation of three-dimensional printing wollastonite bioceramic support

[0036] 1. Raw material preparation:

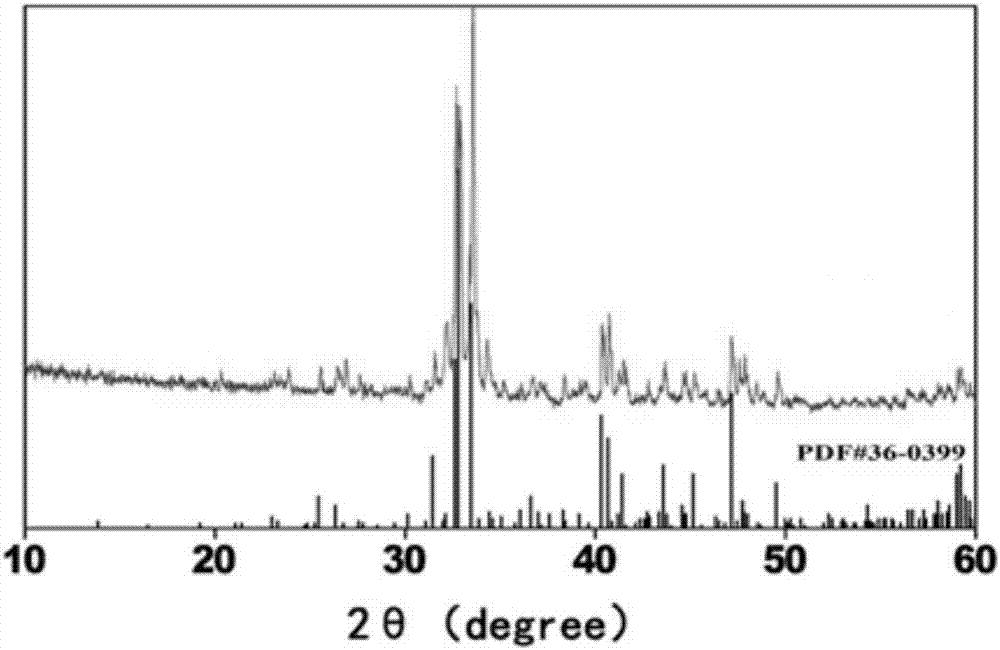

[0037] (1) Synthesis of white wollastonite powder

[0038] The white wollastonite (Ca 7 MgSi 4 o 16 ) powder.

[0039] Take 112mL tetraethyl orthosilicate and 72mL water and 40mL of 2mol L -1 Nitric acid (take 69.4mL of commercially available 65-68% concentrated nitric acid and appropriate amount of water, stir and mix, and then dilute to 500mL to obtain 2mol·L-1 nitric acid), mix, stir and hydrolyze for 0.5h. Add 206.6g calcium nitrate tetrahydrate and 64.1g magnesium nitrate successively, and stir for 5h. Sealed and aged at 60°C for 24h, then dried at 120°C for 48h to obtain a xerogel. After the xerogel is ball milled, it is calcined at 1150° C. for 3 hours, and after natural cooling, it is ball milled and passed through a 200-mesh sieve to obtain the white wollastonite powder.

[0040] (2) Preparation of binder aqueous solution ...

Embodiment 2

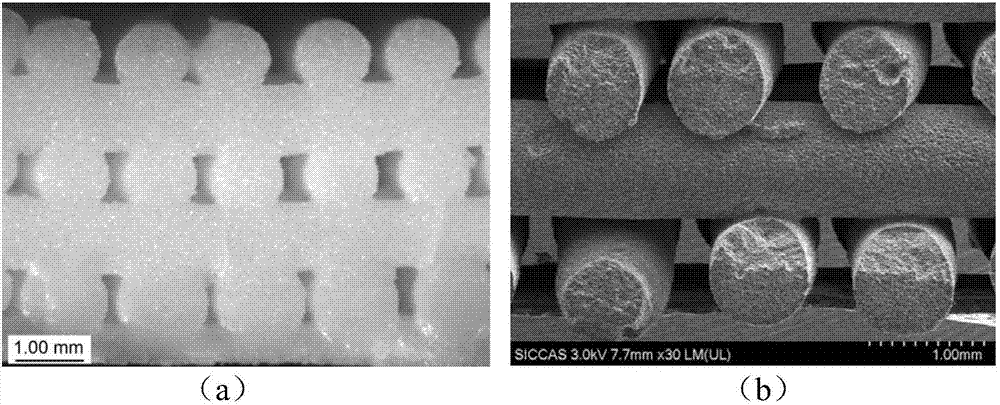

[0050] Embodiment 2, preparation of three-dimensionally printed wollastonite bioceramic scaffold with fine structure

[0051] 1. Raw material preparation:

[0052] (1) Synthesis of wonotlite powder, the raw materials and method are the same as in Example 1.

[0053] (2) The preparation of aqueous binder solution, raw material and method are identical with embodiment 1.

[0054] (3) Preparation of sintering aids

[0055] The sintering aid chooses the purchased 45S5 bioactive glass powder.

[0056] (4) Preparation of 3D printing equipment

[0057] The 3D printer uses Nano-Plotter produced by German GeSiM company TM 2.1, the feeding air pressure is 2.0-3.0 atmospheres, the printing speed is 6.5mm / s, and the inner diameter of the printing needle is 0.41mm.

[0058] 2. Three-dimensional printing preparation of wonotlite bioceramic scaffolds:

[0059] (1) Weigh 4.3g of wonotlite powder, 0.7g of bioglass powder, and 2.8g of binder aqueous solution to fully reconcile and mix to...

Embodiment 3

[0063] Example 3, Preparation of Disc-shaped Three-dimensionally Printed White Notlite Bioceramic Scaffold

[0064] 1. Raw material preparation:

[0065] (1) Synthesis of wonotlite powder, the raw materials and method are the same as in Example 1.

[0066] (2) Preparation of binder aqueous solution

[0067] The binder is polyvinyl alcohol (polymerization degree: 1750±50). Weigh 6g of purchased polyvinyl alcohol into 100ml of boiling water, stir until dissolved, and obtain an aqueous binder solution.

[0068] (3) Preparation of sintering aids

[0069] The sintering aid chooses the purchased 45S5 bioactive glass powder.

[0070] (4) Preparation of 3D printing equipment

[0071] The 3D printer uses the Nano-Plotter TM 2.1 produced by GeSiM Company in Germany, the feeding air pressure is 2.5-3.5 atmospheres, the printing speed is 6.0mm / s, and the inner diameter of the printing needle is 0.41mm.

[0072] 2. Three-dimensional printing preparation of wonotlite bioceramic scaffo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com