Ion doping and protein dipping double modified porous calcium phosphate ceramic and preparation method thereof

A technology of porous calcium phosphate and ion doping, which is applied in the field of ion doping and protein impregnation double-modified porous calcium phosphate ceramics and its preparation, which can solve the problems affecting clinical application, weak binding force, poor mechanical properties, etc., and achieve good Effects of promoting vascularization, promoting adhesion, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the silk fibroin solution involved in the present invention is the method disclosed in Chinese patent CN 102516777 A.

[0044] The preparation of calcium phosphate powder involved in the present invention, wherein the preparation of β-tricalcium phosphate powder refers to the literature Y. Pan, J.L. Huang, C.Y. Shao. Preparation of β-TCP with high thermal stability by solid reaction route. J. Mater. Sci. 2003;38;1049-1056. References for the preparation of hydroxyapatite powder Jiming Zhou, Zhang X., Chen J. High temperature characteristics of synthetic hydroxyapatite. Journal of Materials Science: Materials in Medicine. 1993;4;83- 85. The preparation of α-tricalcium phosphate powder refers to the literature Duncan Jo, MacDonald, James F, et al. The role of the chemical composition of monetite on the synthesis and properties of α-tricalcium phosphate. Materials science and engineering: C. 2014; 34;123-129.

[0045] The preparation methods of t...

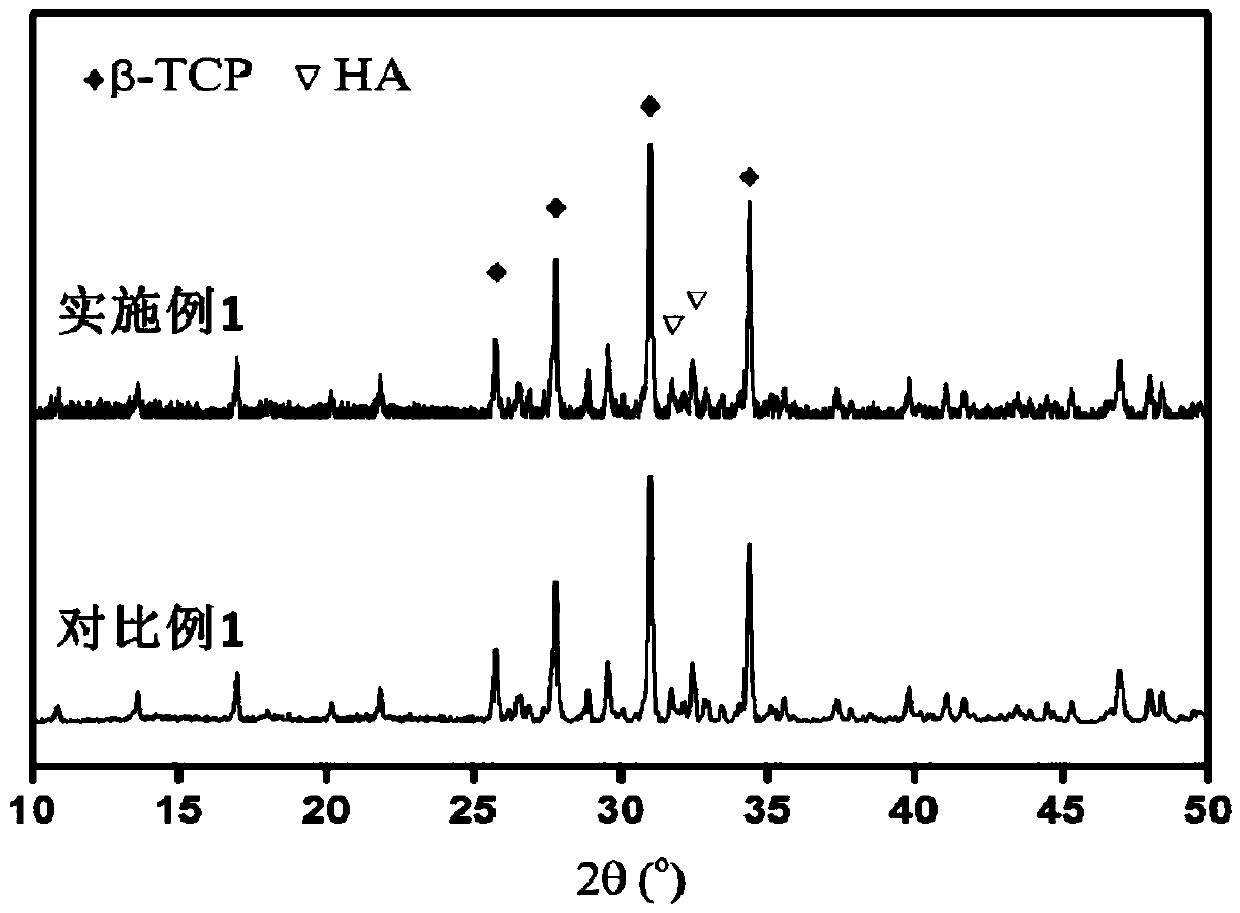

Embodiment 1

[0047] In this example, β-tricalcium phosphate powder doped with 1 mol.% zinc ions and hydroxyapatite powder doped with 1 mol.% were used as raw materials to prepare the ion-doped and protein-impregnated double modified porous Calcium phosphate ceramics, the specific process includes:

[0048] (1) Prepare a silk fibroin solution with a concentration of 6 wt.%.

[0049] (2) Synthesize β-tricalcium phosphate powder doped with 1 mol.% zinc ions and hydroxyapatite powder doped with 1 mol.% zinc ions to form a mixed powder; among them, doped with 1 mol.% The mass ratio of β-tricalcium phosphate powder with zinc ions to hydroxyapatite powder doped with 1 mol.% zinc ions is 83:17;

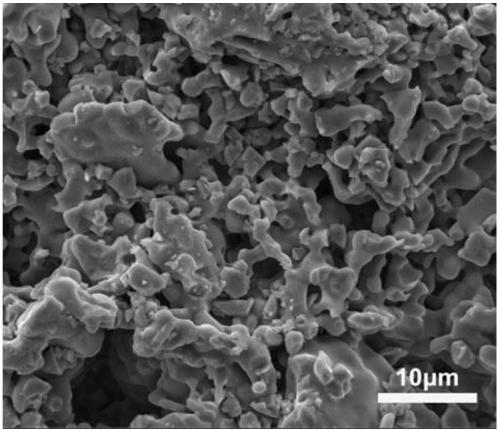

[0050] (3) The zinc ion-doped calcium phosphate powder obtained in step (2) was prepared into a porous calcium phosphate ceramic body by extrusion molding; the temperature was raised to 1200°C at a rate of 2°C / min, and kept for 2 h. Carry out high-temperature sintering to obtain ion-doped porous calcium...

Embodiment 2

[0067] In this example, β-tricalcium phosphate powder doped with 0.5 mol.% zinc ions was used as raw material to prepare the ion-doped and protein-impregnated double modified porous calcium phosphate ceramics. The specific process includes:

[0068] (1) Prepare a silk fibroin solution with a concentration of 7 wt.%;

[0069] (2) Synthesis of β-tricalcium phosphate powder doped with 0.5 mol.% zinc ions;

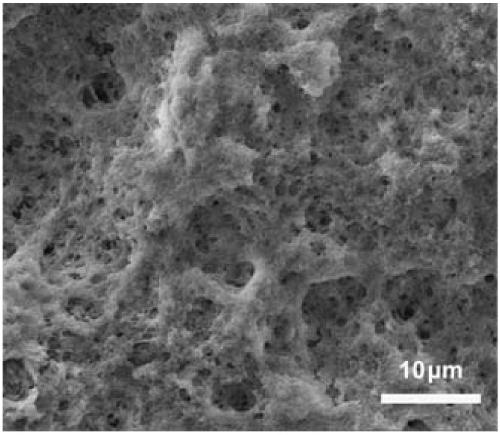

[0070] (3) The zinc ion-doped calcium phosphate powder obtained in step (2) was prepared into a porous calcium phosphate ceramic body by a pore-forming agent method, and the temperature was raised to 1100°C at a rate of 5°C / min, and kept for 3 h. Carry out high-temperature sintering to obtain ion-doped porous calcium phosphate ceramics;

[0071] (4) Immerse the zinc ion-doped porous calcium phosphate ceramic obtained in step (3) in the silk fibroin solution prepared in step (1), the immersion time is 3 min, and the osmotic negative pressure is 0.1 MPa;

[0072] (5) Step (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com