Strontium-doped calcium phosphate ceramic particles for repairing defective alveolar bone, and preparation method of strontium-doped calcium phosphate ceramic particles

A technology of strontium calcium phosphate and ceramic particles, which is applied in the field of strontium-doped calcium phosphate ceramic particles for alveolar bone defect repair and its preparation, can solve the problems of irregular shape, poor bone repair ability, and poor uniformity of calcium phosphate ceramics. Achieve the effect of facilitating migration and growth, convenient implantation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

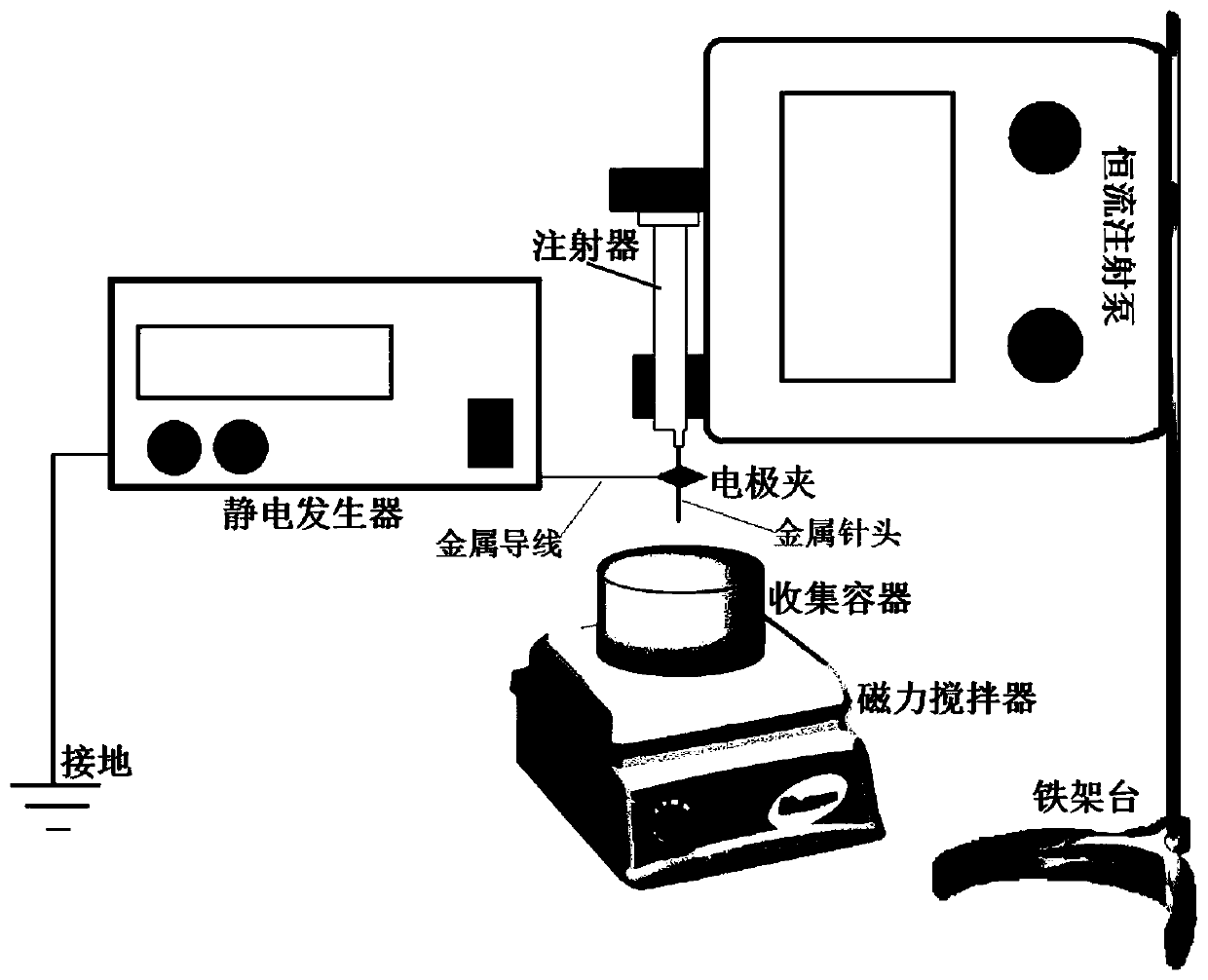

[0043] as attached figure 1 As shown, this embodiment discloses the dropping device adopted by the present invention. The dripping device includes a constant flow injection pump provided with a syringe, an electrostatic generator provided with a metal wire, and a collection container. The needle of the syringe is a metal needle. The ends of the metal wires are connected with electrode clips. The electrode clamp clamps the metal needle and is used for conducting the static electricity generated by the static generator to the metal needle through the metal wire.

[0044] When in use, the syringe containing the foaming slurry is pushed out from the syringe under the action of a constant-flow injection pump, and the foaming slurry enters the metal needle and drips under the action of static electricity on the metal needle. into the strontium salt solution in the collection container to form composite hydrogel microspheres. By controlling the magnitude of the electrostatic volt...

Embodiment 2

[0048] The preparation process of strontium-doped calcium phosphate ceramic particles in the present embodiment is as follows:

[0049] (1) 10g of biphasic calcium phosphate powder, 25mL of 6% sodium alginate aqueous solution, 2mL of 6% methylcellulose solution and 30mL of deionized water were uniformly mixed to obtain calcium phosphate mixed slurry . The biphasic calcium phosphate powder is composed of hydroxyapatite and calcium phosphate, and its Ca / P molar ratio is 1.53.

[0050] (2) Add the obtained calcium phosphate mixed slurry to 5 ml of hydrogen peroxide with a mass concentration of 27%, heat and stir until the slurry forms uniformly sized and abundant bubbles, and obtains a foamed slurry.

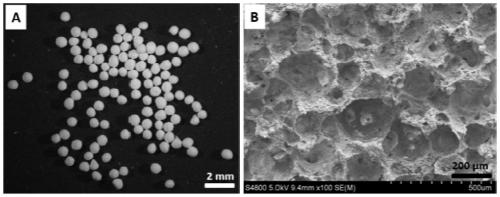

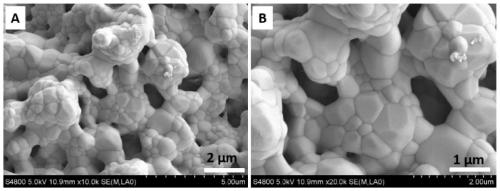

[0051] (3) The resulting foaming slurry is added dropwise to the strontium chloride solution with a mass concentration of 5% by the dripping device of Example 1, and the electrostatic voltage is adjusted to be 5kV to form 1000 μm composite hydrogel microspheres. It is soaked in a...

Embodiment 3

[0056] The preparation process of strontium-doped calcium phosphate ceramic particles in the present embodiment is as follows:

[0057] (1) 10g of hydroxyapatite powder, 25mL of 6% sodium alginate aqueous solution, 2mL of 6% methylcellulose solution and 30mL of deionized water were uniformly mixed to obtain calcium phosphate mixed slurry . The Ca / P molar ratio of this hydroxyapatite powder was 1.67.

[0058] (2) Add the obtained calcium phosphate mixed slurry to 5 ml of hydrogen peroxide with a mass concentration of 30%, heat and stir until the slurry forms uniformly sized and abundant bubbles to obtain a foamed slurry.

[0059] (3) The resulting foaming slurry is added dropwise to the strontium chloride solution with a mass concentration of 5% by the dripping device of Example 1, and the electrostatic voltage is adjusted to be 15kV to form a 500 μm composite hydrogel microsphere. It is soaked in a strontium salt solution until it is completely solidified, and then washed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com