Temperature-sensitive organic-inorganic composite hydrogel material and preparation method thereof

An inorganic composite and hydrogel technology, applied in the direction of inorganic raw material artificial filament, pharmaceutical formulations, prostheses, etc., can solve the problems of dangerous repair materials, limited osteogenic efficiency, high price, etc., and improve osteogenic biological activity. , Improve clinical operability, controllable effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

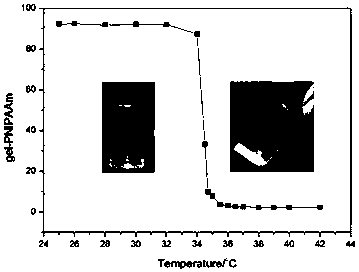

Embodiment 1

[0025] (1) Dissolve 5g of gelatin in 40ml of deionized water, add 1.67g of α-bromoisobutyric acid, add 2.3g of 1-ethyl-3-[3-dimethylaminopropyl]carbodiimide and N -Hydroxysuccinimide 0.55g at 40 o C reacted for 24 hours, and purified by ethanol precipitation to obtain brominated gelatin; dissolve 2 g of brominated gelatin in 20 ml of dimethyl sulfoxide, add 10 g of N-isopropylacrylamide, add 1, 1, 4, 7, 7 methyl di Ethylenetriamine 200μl, add 0.1g cuprous bromide after purging nitrogen to deoxygenate, at 30 o C was reacted for 1 hour; the reaction mixture was poured into deionized water to terminate the reaction, and after purification with aluminum oxide chromatographic column to remove cuprous bromide, deionized water was dialyzed to remove unreacted N-isopropylacrylamide and 1, 1,4,7,7-methyldiethylenetriamine, poly(N-isopropylacrylamide)-grafted gelatin (Gel-g-PNIPAAm-1) was obtained after lyophilization. The critical solution temperature (LCST) of its aqueous solution i...

Embodiment 2

[0029] (1) The preparation of Gel-g-PNIPAAm-1 is the same as step (1) of Example 1.

[0030] (2) After mixing triethyl phosphate, ethanol and water at a molar ratio of 1:3:3, add 0.5% ammonia water as a catalyst to adjust the pH of the system to 9, at 80 o Hydrolyze at C for 24 hours to obtain fully hydrolyzed organic phosphoric acid mixture A; dissolve calcium nitrate tetrahydrate and magnesium nitrate hexahydrate in absolute ethanol at a molar ratio of 95:5 to prepare 3mol / L nitrate Alcoholic solution B; according to the calcium-phosphorus molar ratio of 1.6, the nitrate alcohol solution B is added dropwise in the triethyl phosphate hydrolysis solution A, at 4 o C was stirred and mixed for 2 hours to obtain primary sol solution C; the primary sol was placed at -20 o After C aging for 7 days, the spinning solution was prepared according to the mass ratio of sol:water = 5:1, and polyvinylpyrrolidone (Mn=1,300,000) was added as a spinning aid at a concentration of 4wt.%. After...

Embodiment example 3

[0034] (1) Dissolve 5g of gelatin in 40ml of deionized water, add 3.34g of α-bromoisobutyric acid, add 4.6g of 1-ethyl-3-[3-dimethylaminopropyl]carbodiimide and N -Hydroxysuccinimide 1.1g at 40 o C reacted for 24 hours, and purified by ethanol precipitation to obtain brominated gelatin; dissolve 2 g of brominated gelatin in 20 ml of dimethyl sulfoxide, add 20 g of N-isopropylacrylamide, add 1, 1, 4, 7, 7 methyl di Ethylenetriamine 400μl, add 0.2g cuprous bromide after purging nitrogen to remove oxygen, at 30 o C was reacted for 1 hour; the reaction mixture was poured into deionized water to terminate the reaction, and after purification with aluminum oxide chromatographic column to remove cuprous bromide, deionized water was dialyzed to remove unreacted N-isopropylacrylamide and 1, 1,4,7,7-methyldiethylenetriamine, poly(N-isopropylacrylamide)-grafted gelatin (Gel-g-PNIPAAm-2) was obtained after lyophilization. The critical solution temperature (LCST) of its aqueous solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com