Magnetic nanoparticle/calcium phosphate ceramic composite porous material and preparation method thereof

A technology of magnetic nanoparticles and calcium phosphate ceramics, which is applied in the field of biomedical materials, can solve the problems of difficult to accurately control the content of magnetic nanoparticles, uneven distribution, poor controllability, etc., and achieve good bone repair and bone induction ability, Beneficial for industrial production and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

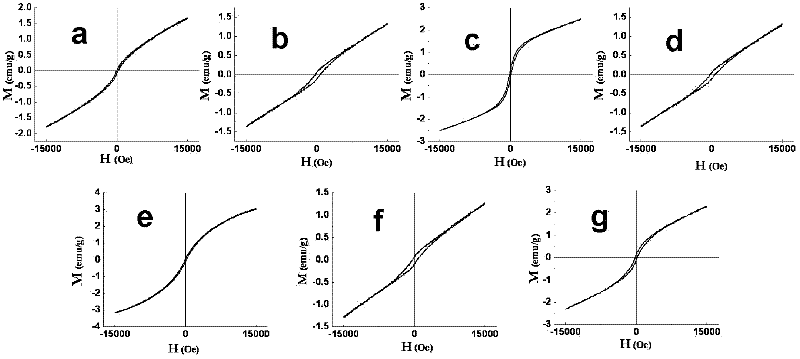

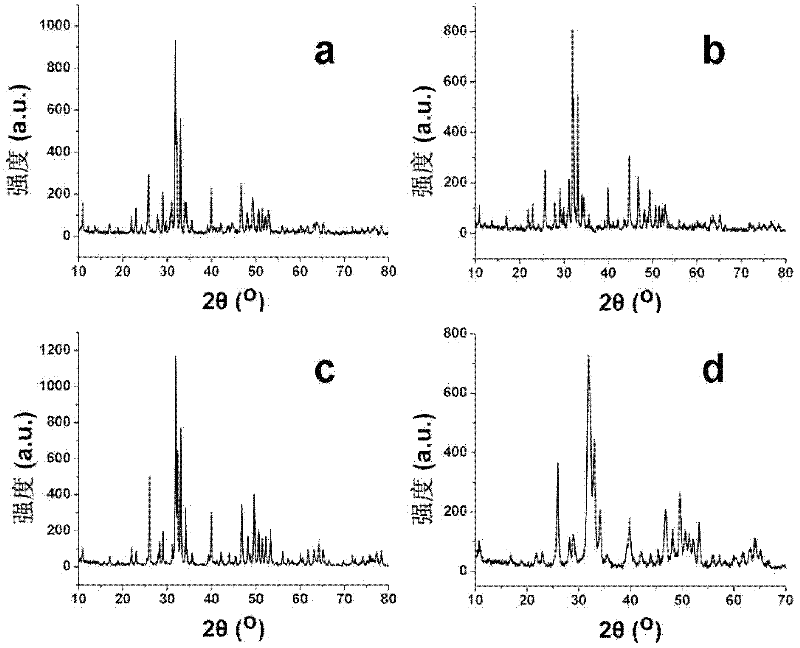

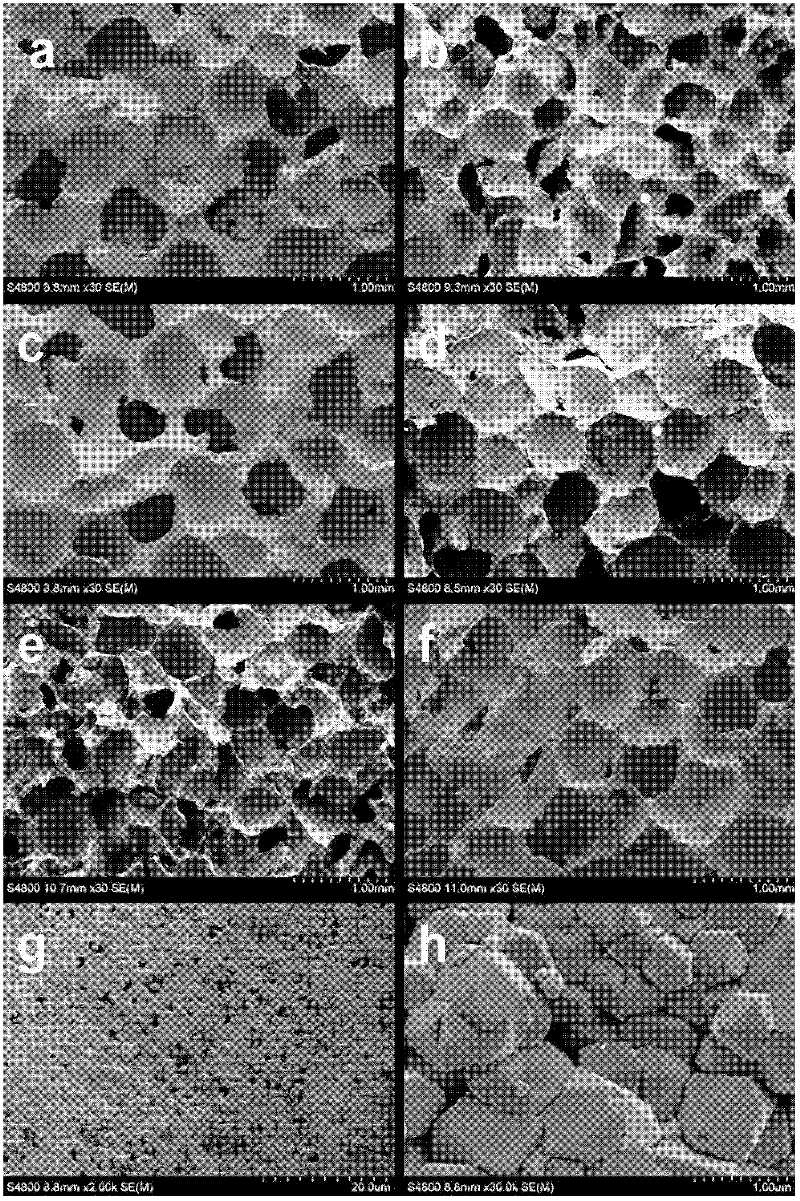

Embodiment 1

[0036] (1) Fe 3 o 4 Preparation of ferrofluid

[0037] Hydrophobic superparamagnetic Fe with an average particle size of 10 nm coated with oleic acid prepared by pyrolysis 3 o 4 Nanoparticles dispersed in n-hexane to make Fe 3 o 4 Fe at a concentration of 10 mg / ml in nanoparticles 3 o 4 Ferrofluid;

[0038] (2) Preparation of composite powder

[0039] Take 10g of hydroxyapatite airflow powder, pre-sinter under normal pressure and 800°C for 8 hours, cool to room temperature, mix with 7ml of polyvinyl alcohol aqueous solution with a concentration of 50mg / ml and 0.1g of triethylene glycol and 50ml of the step (1) Prepared Fe 3 o 4 Grind and mix the magnetic fluid, then put it into a vacuum drying oven and dry it under vacuum for 24 hours at room temperature, take it out after drying and continue grinding until the agglomerated powder is completely broken to obtain a uniformly mixed composite powder;

[0040] (3) Preparation of green body

[0041] Take 6g of stearic ac...

Embodiment 2

[0059] (1) Fe 3 o 4 Preparation of ferrofluid

[0060] Hydrophobic superparamagnetic Fe with an average particle size of 8 nm coated with oleic acid prepared by pyrolysis 3 o 4 Nanoparticles dispersed in n-hexane to make Fe 3 o 4 Fe at a concentration of 10 mg / ml in nanoparticles 3 o 4 Ferrofluid;

[0061] (2) Preparation of composite powder

[0062] Take 10g of hydroxyapatite airflow powder, pre-sinter at normal pressure and 800°C for 8 hours, cool to room temperature and mix with 7ml of polyvinyl alcohol aqueous solution with a concentration of 50mg / ml and 0.1g of triethylene glycol and 20ml of step (1) Prepared Fe 3 o 4 Grind and mix the magnetic fluid, then put it into a vacuum drying oven and dry it under vacuum for 24 hours at room temperature, take it out after drying and continue grinding until the agglomerated powder is completely broken to obtain a uniformly mixed composite powder;

[0063] (3) Preparation of green body

[0064] Take 6g of stearic acid, a...

Embodiment 3

[0069] (1) Fe 3 o 4 Preparation of ferrofluid

[0070] Hydrophobic superparamagnetic Fe with an average particle size of 10 nm coated with oleic acid prepared by pyrolysis 3 o 4 Nanoparticles dispersed in n-hexane to make Fe 3 o 4 Fe at a concentration of 10 mg / ml in nanoparticles 3 o 4 Ferrofluid;

[0071] (2) Preparation of composite powder

[0072] Take 10g of hydroxyapatite airflow powder, pre-sinter at normal pressure and 800°C for 8 hours, cool to room temperature, mix with 7ml of polyvinyl alcohol aqueous solution with a concentration of 50mg / ml and 10ml of Fe prepared in step (1) 3 o 4 Grind and mix the magnetic fluid, then put it into a vacuum drying oven and dry it under vacuum for 24 hours at room temperature, take it out after drying and continue grinding until the agglomerated powder is completely broken to obtain a uniformly mixed composite powder;

[0073] (3) Preparation of green body

[0074] Take 4.5g of pore-forming agent naphthalene with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com