Degradable medical biological MgCa and preparation

An alloy and biological technology, applied in the field of medical metal biological implant materials, can solve problems such as degradation and disappearance, and achieve the effects of low production cost, reduced stress shielding effect, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 315 grams of pure magnesium and 16.4 grams of MgCa30 master alloy, and melt them into Mg-0.7Ca alloy according to the above method. The obtained Mg-0.7Ca alloy is cut into 10×10×5mm 3 Cubic sample, heated to 480 °C in a tube furnace, with N 2 As a protective atmosphere, after 1.5 hours of heat preservation, it was taken out of the furnace and cooled to room temperature to obtain a biodegradable MgCa alloy.

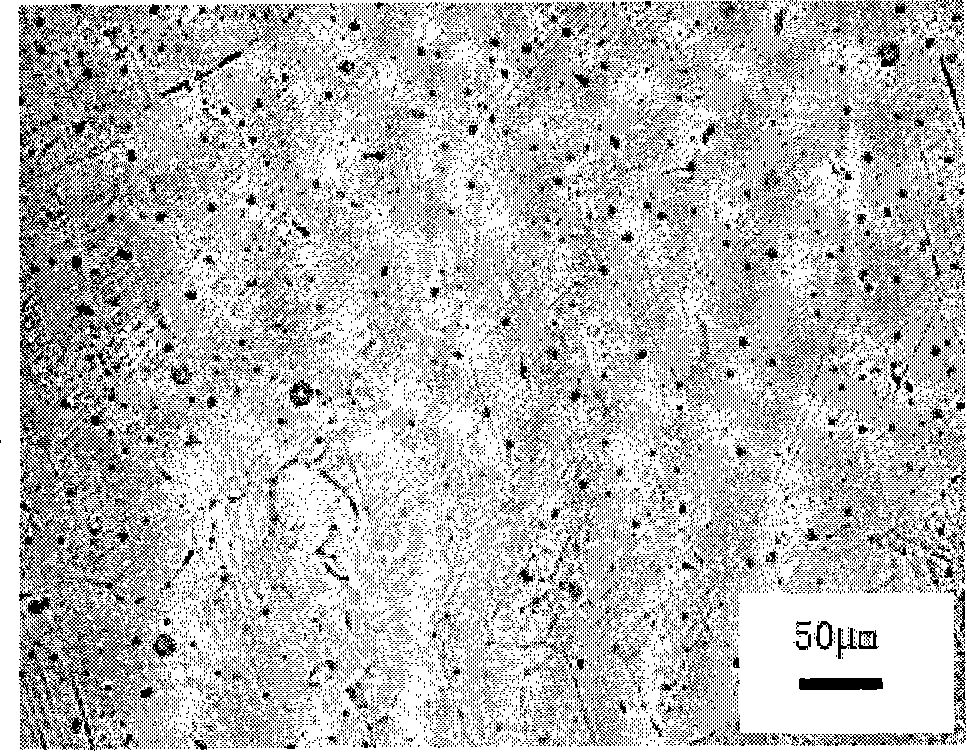

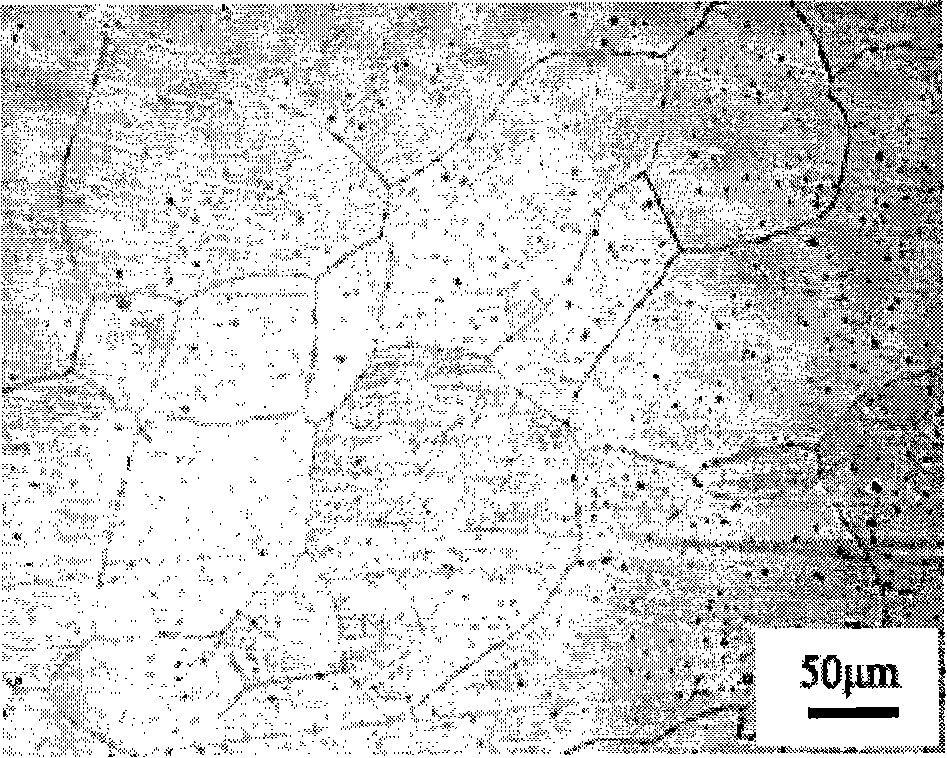

[0032] As-cast metallographic structure of Mg-0.7Ca alloy see figure 1 , the structure of MgCa alloy after heat treatment can be seen figure 2 . The hardness of MgCa alloy after heat treatment is HV75, which is higher than that of pure magnesium HV25.

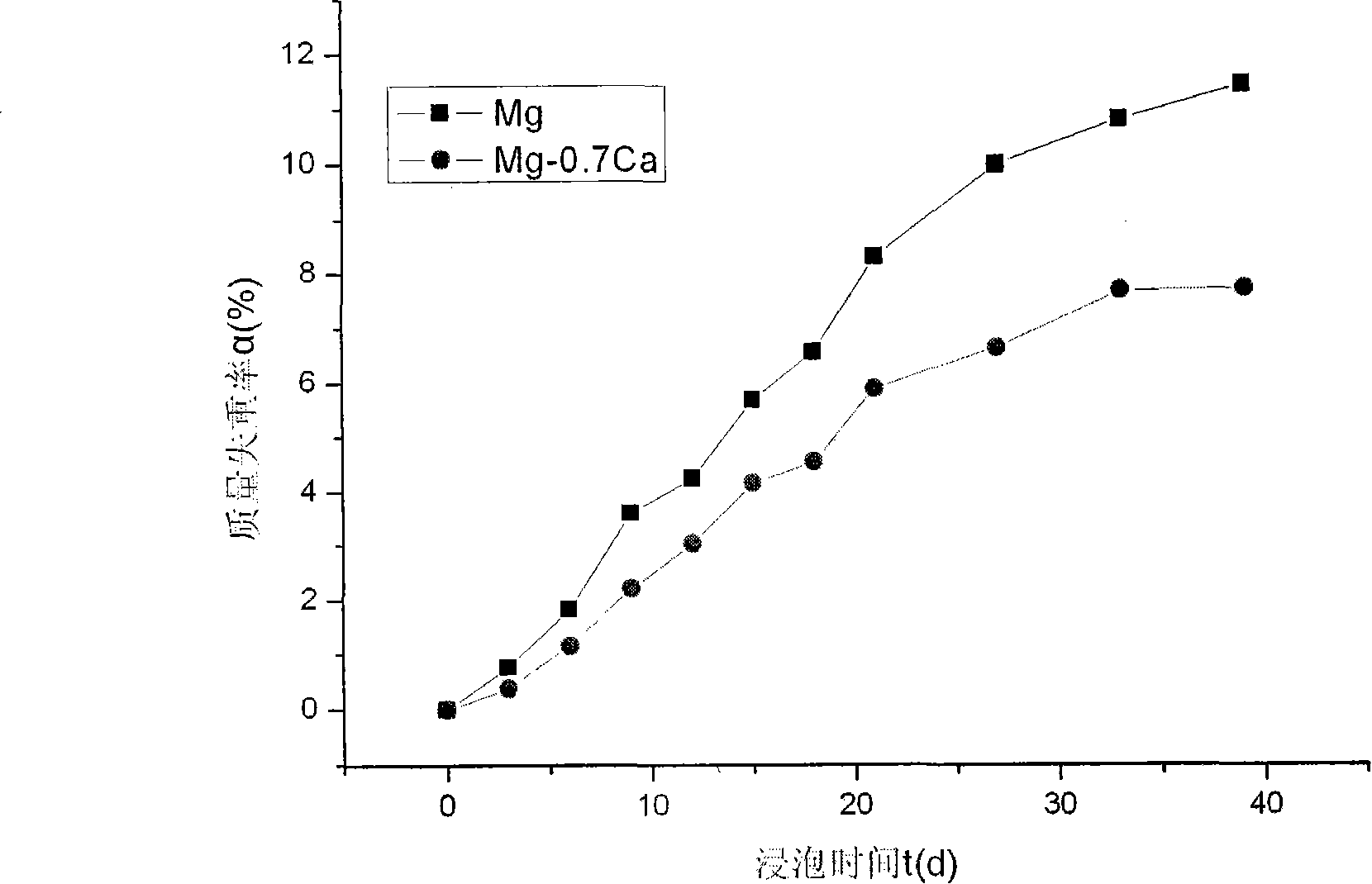

[0033] Grind the heat-treated sample with 800#, 1000#, 1400# sandpaper until the mirror surface is smooth. Then it was ultrasonically cleaned in acetone for 10 minutes, immersed in simulated body fluid (SBF), and its corrosion rate was measured by weight loss method, and compared with pure magnesium that h...

Embodiment 2

[0040] The difference from Example 1 is that during smelting, the pure magnesium is 302 grams, and the MgCa 30 master alloy is 32.8 grams, and the Mg-2.0Ca alloy is made, and the obtained Mg-2.0Ca alloy is heated to 500 ° C, and the holding time is 2 hours. Step is identical with embodiment 1.

[0041] Figure 5For: Mg-2.0Ca alloy cast state, Figure 6 It is the metallographic structure of MgCa alloy after heat treatment. The hardness of MgCa alloy after heat treatment is HV86.

[0042] Figure 7 It is the weight loss curve of Mg-2.0Ca alloy and pure magnesium, it can be seen that the weight loss rate of the alloy is higher than that of pure magnesium. It can be used as a replacement material for human hard tissue that requires rapid degradation, or as a temporary fixation material for hard tissue damage.

[0043] in conclusion:

[0044] The order of the degradation rate of MgCa alloys with different components in SBF from fast to slow is: Mg-2.0Ca>Mg-0.7Ca. After the M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com