Surface nano-scale modified calcium phosphate bioactive ceramic as well as preparation method and application thereof

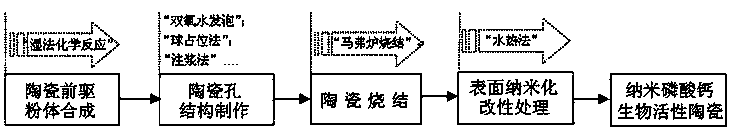

A calcium phosphate biological and active ceramic technology, applied in the field of biomedical materials, can solve problems such as sintering process constraints and bottlenecks, and achieve the effects of enhancing mechanical strength, improving bone-inducing ability, and inhibiting the growth of bone tumor cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

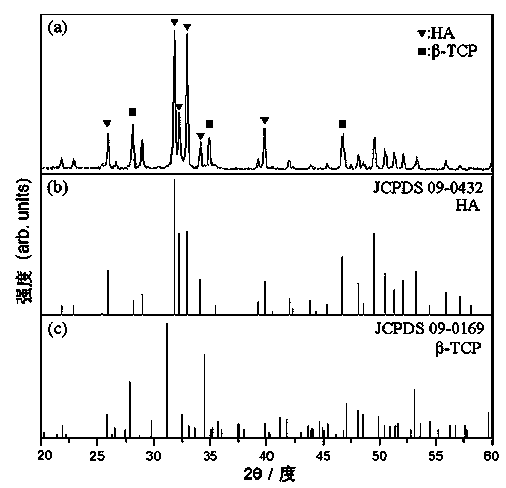

[0068] 1) Synthesize β-phase tricalcium phosphate (β-TCP) powder through "wet chemical reaction" (refer to Biomaterials 2004;25:659-67 for specific steps), dry and air-flow pulverize, and screen with a diameter of 80-160 The dry powder of μm is used as the precursor powder for the preparation of the porous ceramic body;

[0069] 2) Use the "hydrogen peroxide foaming method" to prepare the microporous structure of the matrix calcium phosphate ceramics. Use 5 wt% polyvinyl alcohol and hydrogen peroxide to prepare the ceramic slurry to a slimy state. After stirring evenly, heat and decompose the hydrogen peroxide in a microwave oven to generate gas. Foam ceramic slurry, place the ceramic slurry rich in foam in a mold of 80 × 30 × 30 mm (length × width × height) and dry to prepare a porous ceramic body;

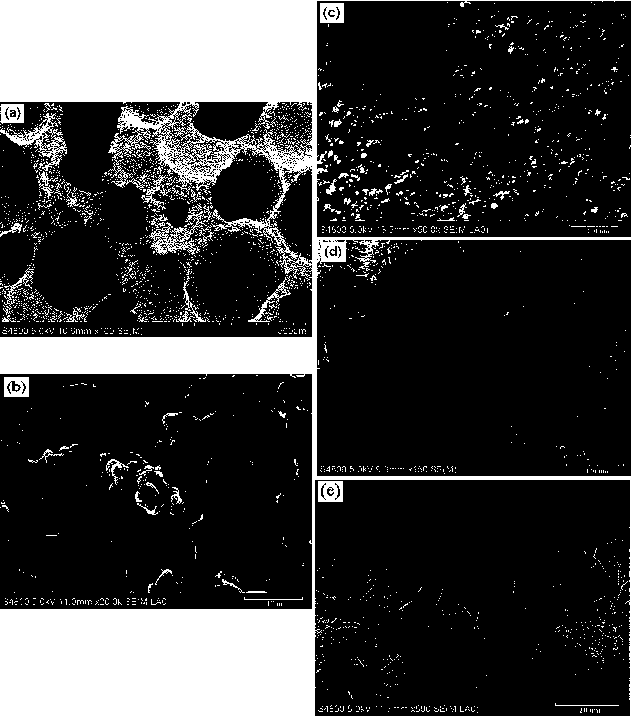

[0070] 3) Put the porous ceramic body into a muffle furnace for sintering, heat up from room temperature to 1100 °C at a rate of 5 °C / min for 2 h for sintering, and then cool wit...

Embodiment 2

[0075] Using biphasic calcium phosphate ceramics (BCP) as the substrate for surface nano-modification treatment, the product preparation process and steps are the same as in Example 1, except that the ceramic powder synthesized by "wet chemical reaction" in step 1) The body is a biphasic calcium phosphate powder. On this basis, the porous ceramic body is made and sintered into porcelain, and then the surface of this biphasic calcium phosphate ceramic is modified by nanometerization. The obtained calcium phosphate active bioceramic material The pore structure is: porosity 75%, macropore diameter 150-300 μm, interpenetrating micro-pore diameter ~10 μm, microscopic grains: 2-10 μm; the ceramic surface is micro-nano whisker-like, the micro-nano The whiskers are 10-20 μm long and about 150 nm in diameter. The whisker density obtained is denser than that in Example 1, but the shape is thinner. This shows that the nano-processing of the surface of calcium phosphate ceramics is contro...

Embodiment 3

[0078] Using pure β-phase tricalcium phosphate ceramics as the substrate to carry out surface nano-modification treatment, the product preparation steps and process are the same as in Example 1, the difference is that the configuration of the surface treatment modification solution in step 4) is selected as phosphoric acid modulation pH = 5.0, immerse the β-TCP ceramic material with a ratio of 1:30 g / ml in the dilute phosphoric acid solution, and raise the temperature to 150 °C at a rate of 5 °C / min in a polytetrafluoroethylene substrate hydrothermal reactor, After reacting for 2 h, the surface was naturally cooled to room temperature to obtain surface nanosized calcium phosphate bioactive ceramics. The pore structure of the obtained calcium phosphate active bioceramic material is: porosity 75%, macropore diameter 150-300 μm, interpenetrating micropore diameter ~10 μm, micro-grains: 2-10 μm; ceramic surface is Micro-nano whisker shape, the micro-nano whisker is 8-15 μm long an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com