Mineralized collagen/bioceramic composite and manufacturing method thereof

A technology of collagen and bioceramics, applied in drug combination, dental preparations, tissue regeneration, etc., can solve the problems of undisclosed application of mineralized collagen, and achieve the effect of reasonable mechanical strength, good mechanical strength and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

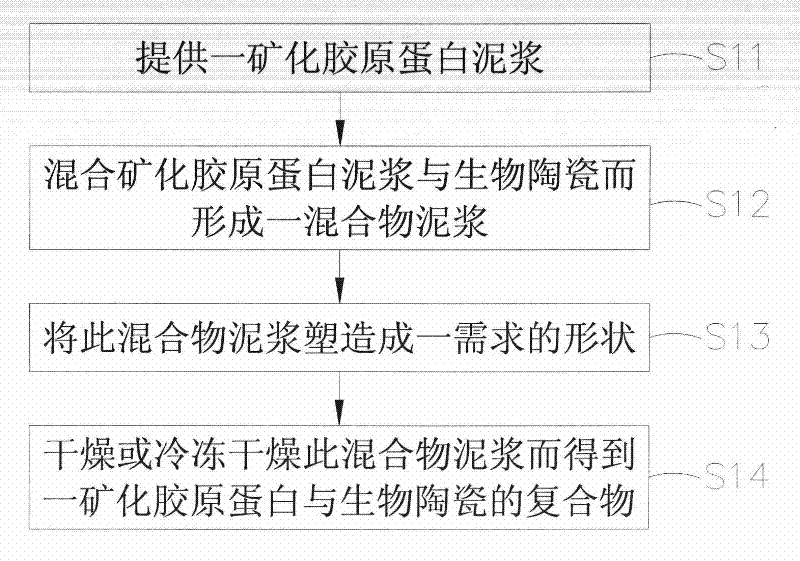

Method used

Image

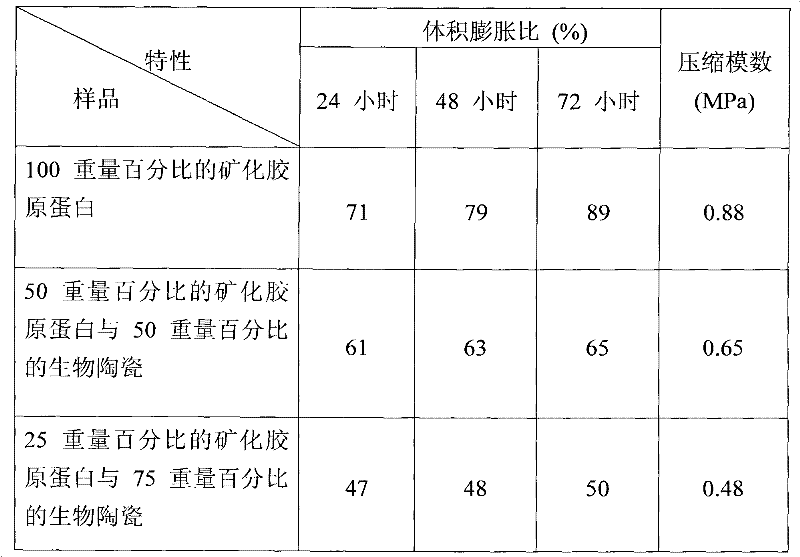

Examples

Embodiment 1

[0041] Preparation of Mineralized Collagen Slurry: Add 1 gram of solid fibrous collagen (Type I collagen) to a container containing 250 ml of purified water. Add 5.3 grams of trisodium phosphate (Na 3 PO 4 12H 2 O). Stir (mix) the aqueous mixture in a blender until the collagen is a homogeneous colloidal slurry. The pH of this collagen is greater than 10.

[0042] Dissolve 3.54 grams of calcium nitrate (Ca(NO 3 ) 2 4H 2 O) in 50 ml of pure water to form an aqueous solution of calcium nitrate. When pouring this calcium nitrate (Ca(NO 3 ) 2) solution in the collagen slurry, keep the collagen slurry in a blender and stir vigorously. Stirring was continued for several minutes, followed by standing still for one hour. After the reaction, the final pH of the collagen slurry remains close to 10 or higher. The slurry was then filtered with a separating funnel and washed several times with pure water until it was free of soluble impurities. If Hydroxyapatite (HA) is calciu...

Embodiment 1-1

[0045] One-half of the above-mentioned purified mineralized collagen slurry was mixed with 5 g of Hydroxyapatite (HA) particles with a particle size ranging from 0.5 mm to 2 mm. The mixed mineralized collagen is then shaped into rectangles and air-dried at room temperature. The weight of the composite of mineralized collagen and HA ceramics after air-drying is 6.25 grams (1.25 g of mineralized collagen and 5 grams of HA particles, i.e. 20% mineralized collagen protein with 80% HA). The composite material remained strong and showed no signs of disintegration after aging in water for several weeks.

Embodiment 2

[0047] Preparation of Mineralized Collagen Slurry: Add 0.5 g of solid fibrous collagen (Type I collagen) to a container containing 100 ml of purified water. Add 5.0 g of trisodium phosphate (Na 3 PO 4 12H 2 O). Stir (mix) the aqueous mixture in a blender until the collagen is a homogeneous colloidal slurry. The pH of this collagen is greater than 10.

[0048] Dissolve 2.53 grams of calcium nitrate (Ca(NO 3 ) 2 4H 2 O) in 50 ml of pure water to form an aqueous solution of calcium nitrate. When pouring this calcium nitrate (Ca(NO 3 ) 2 ) solution in the collagen slurry, keep the collagen slurry in a blender and stir vigorously. Stirring was continued for several minutes, followed by standing still for one hour. After the reaction, the final pH of the collagen slurry remains close to 10 or higher. The slurry was then filtered with a separating funnel and washed several times with pure water until it was free of soluble impurities. If HA is calcium phosphate deposited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com