Treatment method of coarse tin decoppered slag

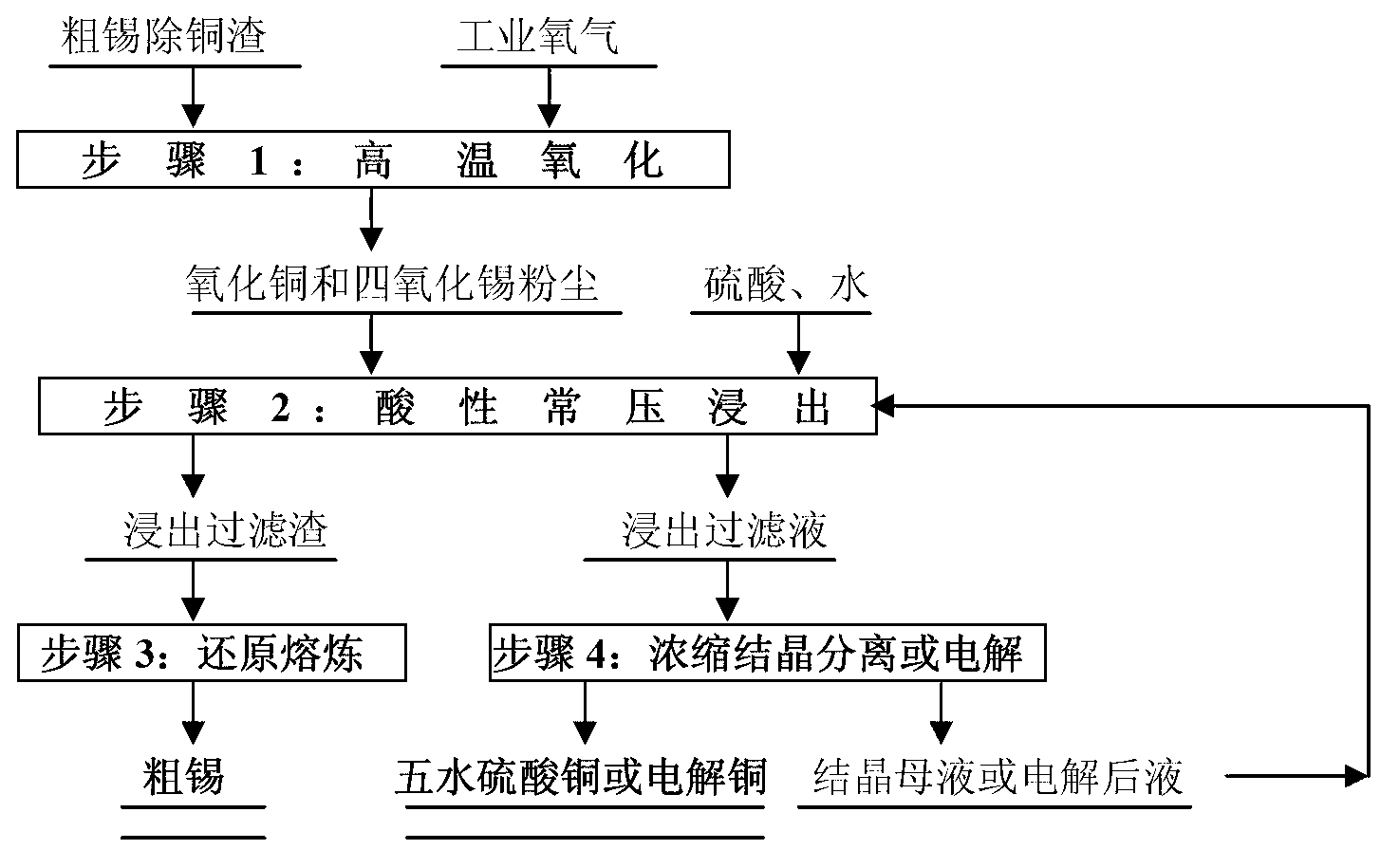

A treatment method and technology of crude tin, which is applied in the field of copper slag removal from crude tin, can solve the problems of long process flow, large power consumption, high production cost, etc., and achieve short process flow, low energy consumption and high direct recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0022] Present embodiment is the first example of the processing method of thick tin copper slag of the present invention, comprises the steps:

[0023] (1) High-temperature oxidation: put 3 tons of coarse tin decopper slag containing 50.5% tin and 19.5% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. 93% oxygen, at a flow rate of 10 cubic meters per hour, is sprayed onto the surface of the coarse tin copper removal slag, and the coarse tin copper removal slag is completely oxidized into dust. The oxidation process lasts for 120 minutes and consumes 1200 cubic meters of industrial oxygen. A total of oxidized 3.3 tons of copper and tin tetroxide dust, the dust contains an average of 45.7% tin and 17.8% copper.

[0024] (2) Acidic leaching at normal temperature and pressure: Put 3.3 tons of dust containing 45.7% tin and 17.8% copper into a leaching tank of 20 cubic meters, and add 15 cubic meters of leach solution with an...

no. 2 example

[0028] Present embodiment is the second example of the processing method of thick tin copper slag of the present invention, comprises the steps:

[0029] (1) High temperature oxidation: put 3 tons of crude tin decopper slag containing 65% tin and 13% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. 97% industrial oxygen is sprayed onto the surface of the coarse tin copper removal slag at a flow rate of 10 cubic meters per hour, and all the coarse tin copper removal slag is oxidized into dust. The oxidation process lasts for 120 minutes and consumes 1200 cubic meters of industrial oxygen, which is collected in total 3.4 tons of copper oxide and tin tetroxide dust, the dust contains an average of 57.3% tin and 11.5% copper.

[0030] (2) Normal temperature and pressure leaching: put 3.4 tons of dust containing 57.3% tin and 11.5% copper into a leaching tank of 20 cubic meters, add 15 cubic meters of leaching solution with a...

no. 3 example

[0034] Present embodiment is the 3rd example of the processing method of thick tin copper slag removal described in the present invention, comprises the steps:

[0035](1) High-temperature oxidation: put 4 tons of crude tin decopper slag containing 75% tin and 8% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. 98.5% industrial oxygen is sprayed onto the surface of the coarse tin copper removal slag at a flow rate of 10 cubic meters per hour, and the coarse tin copper removal slag is completely oxidized into dust. The oxidation process lasts for 160 minutes and consumes 1600 cubic meters of industrial oxygen. 4.7 tons of copper oxide and tin tetroxide dust, the dust contains an average of 63.8% tin and 6.81% copper.

[0036] (2) Normal temperature and pressure leaching: 4.7 tons of dust containing 63.8% tin and 6.81% copper, add 20 cubic meters of leaching tank, add 16 cubic meters of leaching solution with an initial ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com