Flatting agent for epoxy-polyester powder paint and preparation method thereof

A technology of polyester powder and manufacturing method, which is applied in the field of compounds, can solve problems such as poor mechanical properties and easy yellowing, and achieve the effect of solving poor mechanical properties, good mechanical properties, and good extinction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

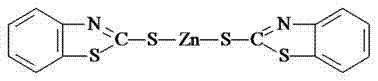

[0033]100 grams of 0.703mol of glycidyl methacrylate, 20 grams of 0.156mol of butyl acrylate, 30 grams of 0.300mol of methyl methacrylate, 50 grams of 0.384mol of hydroxypropyl acrylate, 4 grams of 0.0243mol of azo Diisobutyronitrile was prepared as a dropwise mixed solution. 200g of toluene was added into a 1000ml three-neck flask, while the temperature was raised and stirred. When the temperature reaches 105°C to 110°C, start to add the mixed solution dropwise, and finish the dropwise addition after 80 minutes, and keep warm at 105°C to 110°C for 2.5 hours. The solvent was distilled off under reduced pressure, and the temperature did not exceed 170°C. Synthetic resin is pulverized and sieved through 120 meshes, then mixed with 2-mercaptobenzothiazole zinc salt 75:25 to make matting agent 1.

Embodiment 2

[0035] The synthetic resin in Example 1 was pulverized and sieved through a 120-mesh sieve and mixed with 2-mercaptobenzothiazole zinc salt 85:15 to make matting agent 2.

Embodiment 3

[0037] 80 grams of 0.563mol of glycidyl methacrylate, 30 grams of 0.234mol of butyl acrylate, 30 grams of 0.300mol of methyl methacrylate, 50 grams of 0.384mol of hydroxypropyl acrylate, 10 grams of 0.096mol of styrene , 4 grams of 0.0243mol of azobisisobutyronitrile was made into a dropwise mixed solution. Dissolve 1 gram of 0.0041 mol of benzoyl peroxide in 40 g of toluene to prepare an additional initiator solution. 200g of toluene was added into a 1000ml three-neck flask, while the temperature was raised and stirred. When the temperature reaches 105°C-110°C, start to add the mixed solution dropwise, and finish the dropwise addition after 80 minutes, and keep the temperature at 105°C-110°C for 1 hour. Start adding initiator solution. Keep warm for 2 hours after the addition is completed. The solvent was distilled off under reduced pressure, and the temperature did not exceed 170°C. Synthetic resin is pulverized and sieved through 120 meshes, and mixed with 2-mercaptoben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com