Functional wound surface repairing material and preparation method thereof

A wound repair and functional technology, applied in medical science, bandages, etc., can solve the problems of difficult wound healing, easy adhesion of bacteria, and severe infection caused by growth and reproduction, so as to achieve the goal of not easy to reunite or settle, reduce scar formation, and promote wound healing. The effect of healing growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

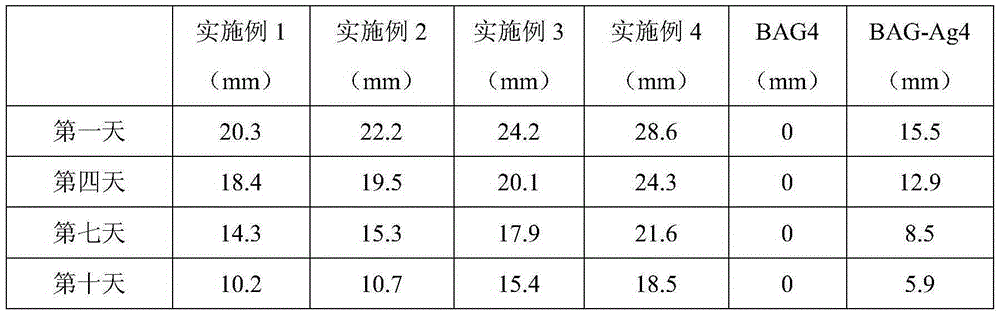

Examples

Embodiment 1

[0023] A functional wound repair material, prepared by the following method:

[0024] (1) Preparation of bioactive glass: take 5g calcium silicate, 0.5g calcium hydrogen phosphate, 0.5g disodium hydrogen phosphate and 3.5g sodium silicate, make a uniform melt at a temperature of 1250°C, cool, Crush to 20-100um to obtain bioactive glass;

[0025] (2) Preparation of silver-loaded bioactive glass powder: Weigh 7 g of bioactive glass, add to 50 g of aqueous solution containing 0.5 g of silver nitrate, stir and react at 40° C. for 4 hours, filter, wash and dry to obtain silver-loaded bioactive glass;

[0026] (3) Preparation of functional wound repair materials: Weigh 160g of deionized water, add the silver-loaded bioactive glass prepared in step (2), 0.2g of chloramphenicol, 15g of hyaluronic acid, stir evenly, and defoam Finally, functional wound repair materials were obtained.

Embodiment 2

[0028] A functional wound repair material, prepared by the following method:

[0029] (1) Preparation of bioactive glass: take 5.2g calcium silicate, 1g calcium hydrogen phosphate, 1.5g disodium hydrogen phosphate and 3.7g sodium silicate, make a uniform melt at a temperature of 1250°C, cool, Crush to 20-100um to obtain bioactive glass;

[0030] (2) Preparation of silver-loaded bioactive glass: Weigh 7 g of bioactive glass, add to 50 g of aqueous solution containing 0.6 g of silver nitrate, stir and react at 50° C. for 4 h, filter, wash and dry to obtain silver-loaded bioactive glass;

[0031] (3) Preparation of functional wound repair material: take 120g deionized water, add the silver-loaded bioactive glass prepared in step (2), 0.4g aureomycin, 20g chitosan, stir evenly, remove After soaking, a functional wound repair material was obtained.

Embodiment 3

[0033] A functional wound repair material, prepared by the following method:

[0034] (1) Preparation of bioactive glass: Weigh 5.5g of calcium silicate, 1.5g of calcium hydrogen phosphate, 1g of disodium hydrogen phosphate and 4g of sodium silicate, make a uniform melt at a temperature of 1250°C, cool and pulverize to 20-100um to obtain bioactive glass;

[0035] (2) Preparation of silver-loaded bioactive glass: Weigh 7 g of bioactive glass, add it to 50 g of aqueous solution containing 0.7 g of silver nitrate, stir and react at 60° C. for 4 hours, filter, wash and dry to obtain silver-loaded bioactive glass;

[0036] (3) Preparation of functional wound repair materials: Weigh 80 g of deionized water, add the silver-loaded bioactive glass prepared in step (2), 0.6 g of oxytetracycline, 10 g of chitosan, and 15 g of sodium alginate , stir evenly, and get a functional wound repair material after defoaming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com