2-mercaptobenzothiazole refining method

A technology of mercaptobenzothiazole and purification method, applied in the direction of organic chemistry and the like, can solve the problems of low purity of 2-mercaptobenzothiazole, large amount of organic solvent, large amount of waste water, etc., and achieves easy industrial production, low environmental pollution, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

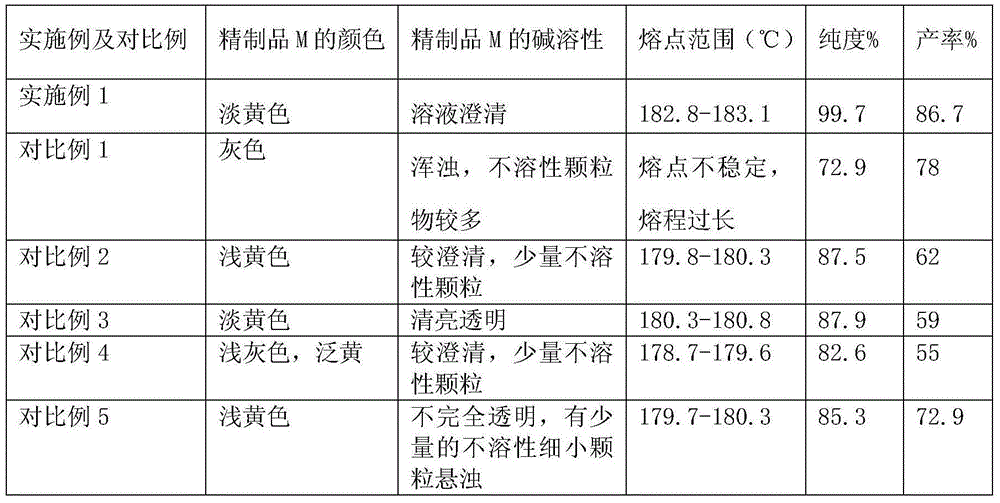

Examples

Embodiment 1

[0029] Weigh 9g of crude 2-mercaptobenzothiazole, crush it, and put it into a 250ml three-neck flask. Put the three-necked flask into a 70°C constant temperature oil bath, and install a reflux device. Weigh 42g of toluene and 21g of acetone, pour them into a three-necked flask, start stirring, the stirring rate is 120r / min, and the stirring time is 10min. The crude 2-mercaptobenzothiazole is completely dissolved in the mixed solvent of toluene and acetone, and is filtered by hot suction. Suction filtered solution and ash. Dry the ash, transfer the filtered solution to a small beaker, and then transfer it to a three-neck flask, install a distillation device, raise the temperature to 85°C, and continue stirring at a stirring rate of 120r / min. When the distillate volume reaches 1 / 6 of the composite solvent volume , the distilled solution is turbid, stop the distillation, pour out the distilled solution, stir and cool the solution to room temperature, 2-mercaptobenzothiazole is p...

Embodiment 2

[0031]Weigh 9g of crude 2-mercaptobenzothiazole, crush it, and put it into a 250ml three-neck flask. Put the three-necked flask into a 50°C constant temperature oil bath, and install a reflux device. Take by weighing 54g toluene, 27g isopropanol, pour into a three-necked flask, start heating and reflux, the stirring rate is 80r / min, and the stirring time is 10min, the thick 2-mercaptobenzothiazole is completely dissolved in the mixed solvent of toluene and acetone, heat Suction filtration to obtain suction filtration solution and ash. Dry the ash, transfer the filtered solution to a small beaker, and then transfer it to a three-necked flask, install a distillation device, raise the temperature to 60°C, and continue stirring at a stirring rate of 170r / min. When the distillate volume reaches 1 / 6 of the composite solvent volume , the distilled solution is turbid, stop the distillation, pour out the distilled solution, stir and cool the solution to room temperature, 2-mercaptoben...

Embodiment 3

[0033] Weigh 90g of crude M, crush it, and put it into a 1000ml three-neck flask. Put the three-necked flask into a 90°C constant temperature oil bath, and install a reflux device. Weigh 270g of toluene and 90g of isopropanol, pour them into a three-necked flask, start heating and reflux, the stirring rate is 170r / min, and the stirring time is 100min. Filter solution and ash. Dry the ash, transfer the filtered solution to a small beaker, and then transfer it to a three-necked flask, install a distillation device, raise the temperature to 100°C, and continue stirring at a stirring rate of 80r / min. When the distillate volume reaches 1 / 6 of the composite solvent volume , the distilled solution is turbid, stop the distillation, pour out the distilled solution, stir and cool the solution to room temperature, 2-mercaptobenzothiazole is precipitated, and the filter cake and filtrate are obtained by suction filtration, and the color of the filter cake is yellow. Move the filter cake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com