Engine antifreezing solution

A technology of antifreeze and engine, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as poor stability, cooling system failure, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Add 400kg of ethylene glycol into the reaction kettle, start stirring, add 1.5kg of benzotriazole under stirring, and fully stir to dissolve. Then 500kg of deionized water was slowly added into the reaction kettle under stirring, and then 1.2kg of sodium molybdate, 12kg of sodium benzoate, 0.4kg of hydrolyzed polymaleic anhydride, and 1.8kg of sodium 2-mercaptobenzothiazole were added in sequence, and stirred to dissolve. Then 14kg of sodium hydroxide, 8kg of isooctanoic acid, and 16.8kg of sebacic acid were simultaneously charged into the reaction kettle, stirred and dissolved transparently. Finally, use the remaining sodium hydroxide to adjust the pH to 8.5-10, mix the defoamer and dye with the remaining amount of deionized water, and add it to the reaction kettle.

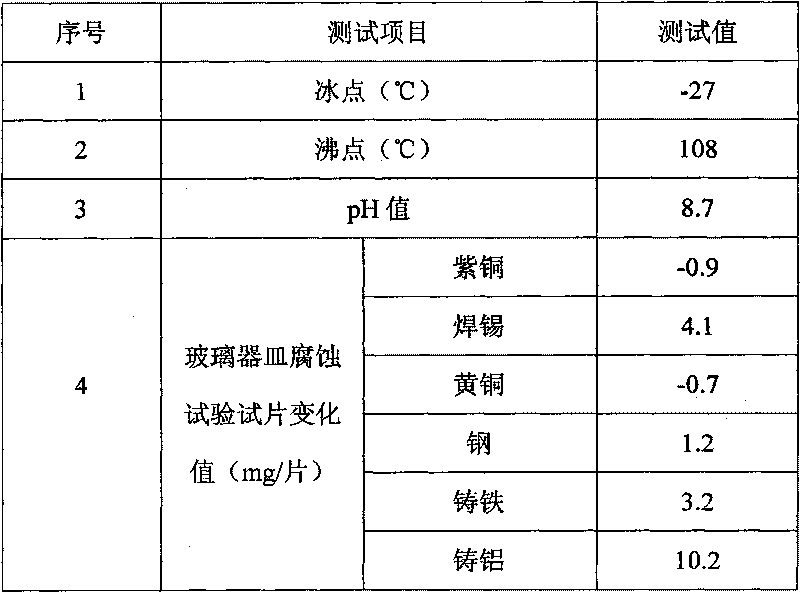

[0057] The main indicators in this example are as follows:

[0058]

Embodiment 2

[0060] Add 600kg of ethylene glycol into the reaction kettle, start stirring, add 2.8kg of benzotriazole under stirring, and fully stir to dissolve. Then 300kg of deionized water was slowly added into the reactor under stirring, and then 2kg of sodium molybdate, 24kg of sodium benzoate, 1.6kg of hydrolyzed polymaleic anhydride, and 3kg of sodium 2-mercaptobenzothiazole were added in sequence, and stirred to dissolve. Then 20kg of sodium hydroxide, 11kg of isooctanoic acid, and 28.5kg of sebacic acid were simultaneously charged into the reaction kettle, stirred and dissolved transparently. Finally, use the remaining sodium hydroxide to adjust the pH to 8.5-10, mix the defoamer and dye with the remaining amount of deionized water, and add it to the reaction kettle.

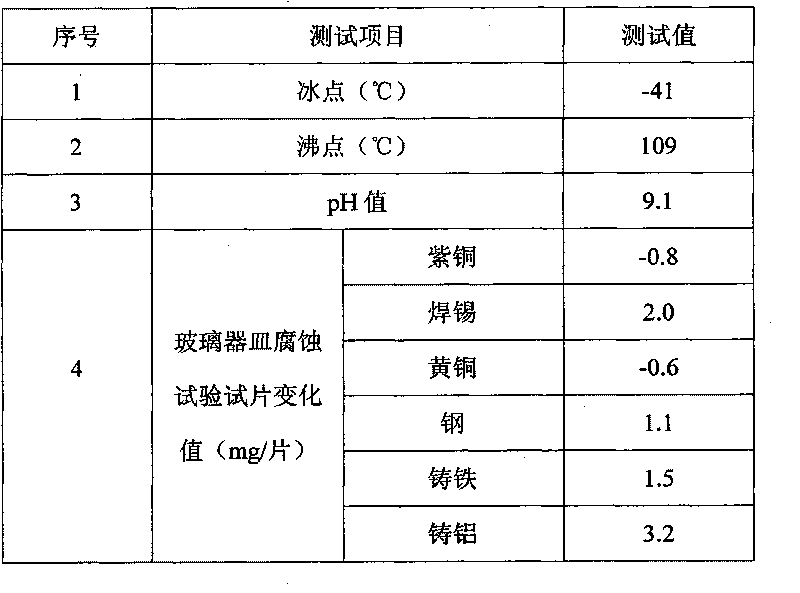

[0061] The main indicators in this example are as follows:

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com