Electric cylinder used for magnetic transmission

A technology of magnetic transmission and electric cylinder, which is applied in the direction of electric components, transmission devices, permanent magnet clutches/brakes, etc., can solve problems such as screw instability, avoid instability, improve service life and protection level, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

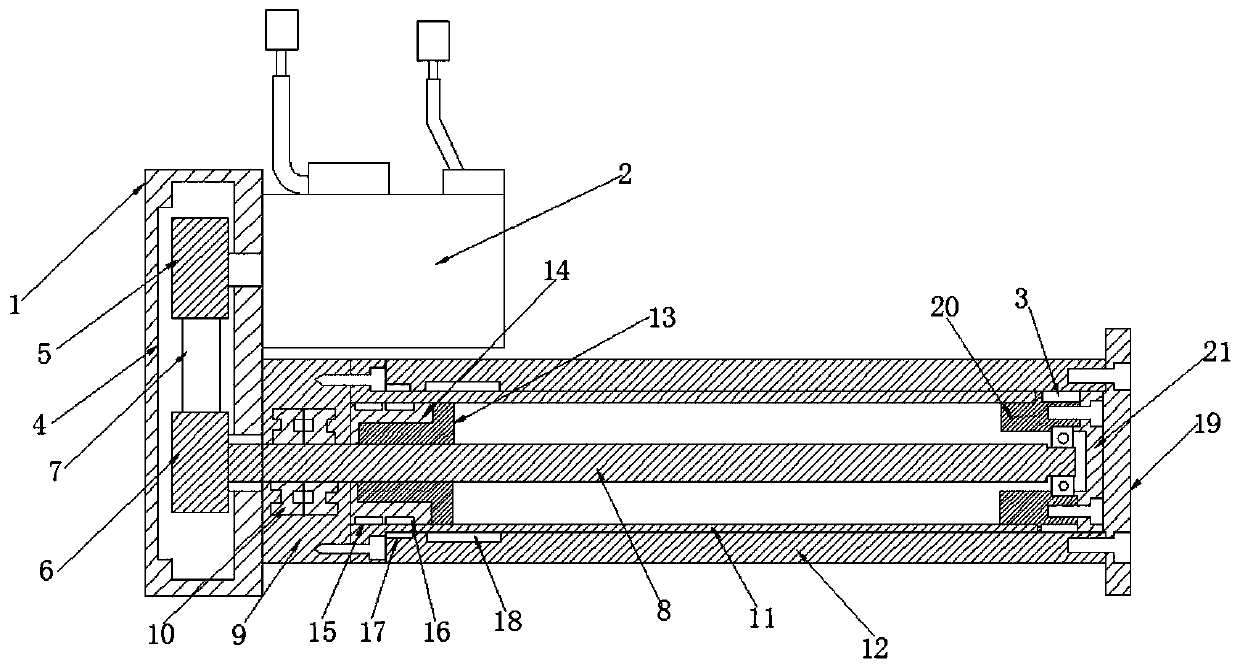

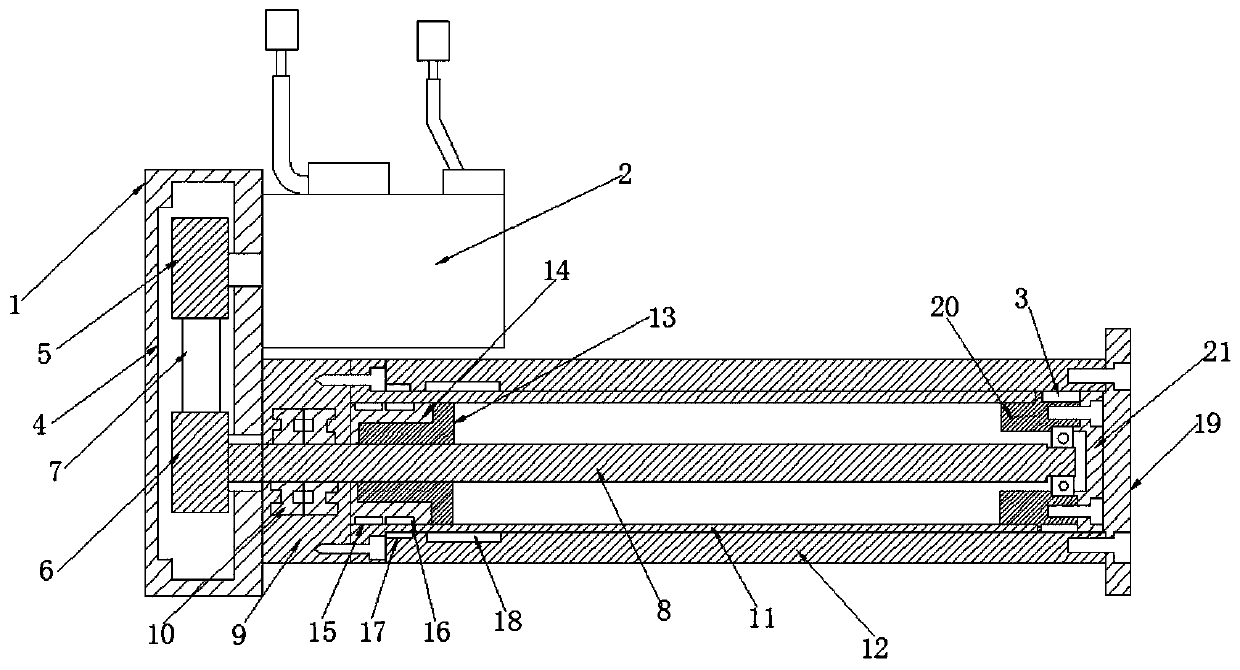

[0018] Embodiment one, such as figure 1 As shown, an electric cylinder for magnetic transmission according to an embodiment of the present invention includes a base 1, a motor 2 is provided on one side of the base 1, and a cavity 4 is provided on the inner side of the base 1. The output shaft of the motor 2 is provided with a belt pulley 5 at the inner upper end of the cavity 4, and the inner lower end of the cavity 4 is provided with a belt pulley 2 6, between the belt pulley 5 and the belt pulley 2 6 A synchronous belt 7 is provided between them, a ball screw 8 is interspersed in the pulley 2, a bearing seat 9 is provided at the lower end of one side of the base 1, and a cylinder body 11 is provided at one side of the bearing seat 9, The outer side of the cylinder 11 is covered with a piston rod 12 , the ball screw 8 and inside the cylinder 11 are covered with a ball nut 13 , and the outer side of the ball nut 13 is covered with a nut sleeve 14 , the nut sleeve 14 is equipp...

Embodiment 2

[0019] Embodiment two, such as figure 1 As shown, the motor 2 is connected in parallel with the cylinder body 11 and the piston rod 12 in parallel.

Embodiment 3

[0020] Embodiment three, such as figure 1 As shown, the strong magnetic steel one 16 and the strong magnetic steel two 17 are permanent magnetic steels, and the magnetism between the two is opposite, so that the strong magnetic steel one 16 drives the strong magnetic steel two 17 sports.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com