On-line repair method for bellows

A repair method and technology for corrugated pipes are applied in the field of online repair of corrugated pipes and online repair of corrugated pipes, which can solve problems such as affecting the shrinkage function of corrugated pipes, affecting the service life of pipe networks, and increasing additional loads of pipelines, so as to protect the safety of life and property. , to ensure stability and continuity, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: On-line repair of the leakage points on several corrugated pipes on a certain blast furnace gas pipeline.

[0030] (1) Quick plugging

[0031] Carry out on-site inspection, analysis and testing of bellows leakage status and propose treatment measures. It can be dealt with according to points, lines, surfaces, etc. If necessary, anti-expansion treatment should be carried out first to prevent further expansion of the leak. If the leak is large, it should be plugged with fiber fabric first; Use a flexible composite adhesive to stick one or several layers of glass fiber cloth to plug the leak, and then cover a reinforced metal sheet on the glass fiber cloth; there should be a sealing surface of 10-15mm around the leak. Carry out 24-hour inspection on the quick plugging site to ensure that the leak will not leak again in a short period of time.

[0032] (2) Pretreatment of the repaired surface

[0033] Pollution, oxidation, rust, etc. on the metal surface will ...

Embodiment 2-4

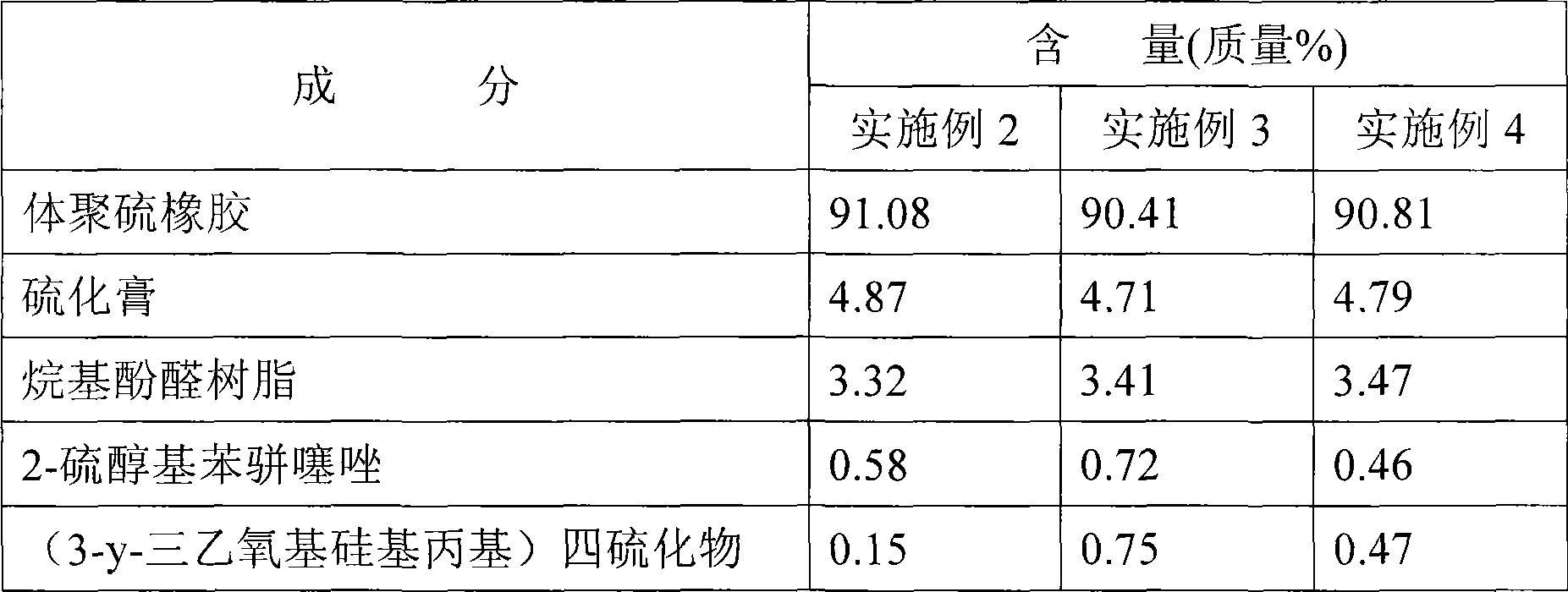

[0044] Examples of the preparation of flexible composite adhesives are shown in Table 1:

[0045]

[0046] The corrugated pipe repaired by the flexible composite adhesive of the invention can work normally for 3 to 5 years in outdoor natural environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com