High-temperature-resistant halogen-free flame-retarding thermoplastic elastomer and preparation method of high-temperature-resistant halogen-free flame-retarding thermoplastic elastomer

A thermoplastic elastomer and high temperature resistant technology, applied in the field of thermoplastic elastomer materials, can solve problems such as affecting the high temperature resistance of products, affecting the physical and mechanical properties of products, and reducing thermal aging of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

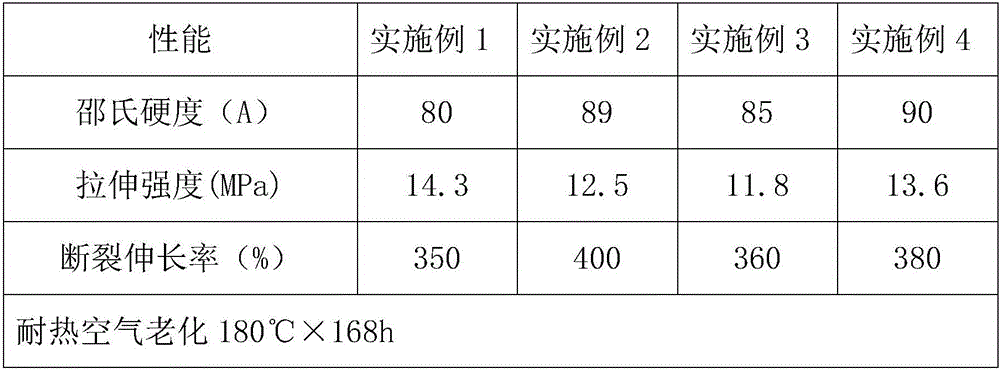

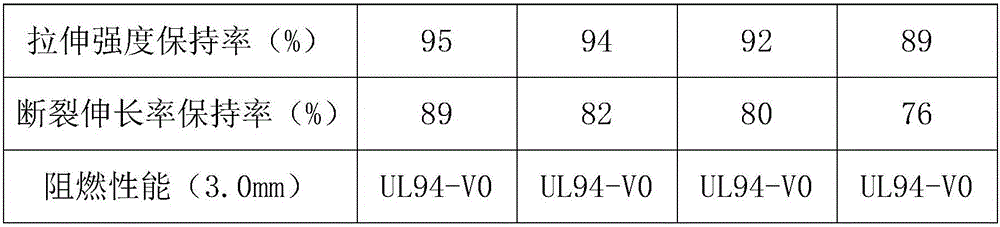

Examples

Embodiment 1

[0023] A high-temperature-resistant halogen-free flame-retardant thermoplastic elastomer, the raw materials of which include by weight: 60 parts of EVA, 45 parts of EPDM, 15 parts of ethylene-octene copolymer, 15 parts of high-density polyethylene, and 5 parts of organomodified siloxane , 30 parts of ammonium polyphosphate, 2 parts of aluminum hydroxide, 3 parts of zinc borate, 1 part of sulfur, 1.5 parts of accelerator TMTD, 0.5 parts of accelerator CZ, 2 parts of zinc oxide, 1 part of anti-aging agent RD, 18 parts of calcium carbonate, 3 parts of quartz powder, 10 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 5 parts of naphthenic white oil, 2 parts of phenolic antioxidant, 0.2 part of lubricant, 3 parts of silicone powder;

[0024] Wherein, the method for preparing the organomodified siloxane includes: heating 10 parts of glycerin to 230° C. under the condition of nitrogen protection, adding sodium hydroxide as a catalyst for polymerization reaction, an...

Embodiment 2

[0026] A high-temperature-resistant halogen-free flame-retardant thermoplastic elastomer, the raw materials of which include by weight: 80 parts of EVA, 25 parts of EPDM, 35 parts of ethylene-octene copolymer, 1 part of high-density polyethylene, and 20 parts of organomodified siloxane , 10 parts of ammonium polyphosphate, 5 parts of aluminum hydroxide, 1 part of zinc borate, 5 parts of sulfur, 0.5 parts of accelerator TMTD, 2 parts of accelerator CZ, 0.5 parts of zinc oxide, 3 parts of anti-aging agent RD, 4 parts of calcium carbonate, 5 parts of quartz powder, 5 parts of maleic anhydride grafted ethylene-propylene copolymer, 20 parts of aromatic white oil, 0.5 parts of amine antioxidant, 2 parts of magnesium stearate, 1 part of silicone masterbatch;

[0027] Wherein, the content of vinyl acetate in the EVA is 45wt%, and its melt index is measured as 50g / 10min at 190°C and 2.16kg according to ASTM D1238; the third polymerizable monomer of the EPDM is ethylene norbornene Alken...

Embodiment 3

[0030] A high-temperature-resistant halogen-free flame-retardant thermoplastic elastomer, its raw materials include 65 parts by weight of EVA, 40 parts of EPDM, 20 parts of ethylene-octene copolymer, 10 parts of high-density polyethylene, 9 parts of organomodified siloxane, 25 parts of ammonium polyphosphate, 3 parts of aluminum hydroxide, 2 parts of zinc borate, 2 parts of sulfur, 1.2 parts of accelerator TMTD, 0.8 parts of accelerator CZ, 1.6 parts of zinc oxide, 1 part of anti-aging agent RD, 12 parts of calcium carbonate, quartz 3 parts of powder, 8 parts of maleic anhydride grafted ethylene-octene copolymer, 8 parts of paraffin-based white oil, 1.5 parts of thiobisphenol antioxidant, 0.5 part of stearic acid, and 2 parts of silicone oil;

[0031] Wherein, the content of vinyl acetate in the EVA is 35wt%, and its melt index is measured as 55g / 10min according to ASTM D1238 at 190°C and 2.16kg; the third polymerizable monomer of the EPDM is ethylene norbornene Alkenes with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com