Ion liquid high-temperature-resistant conveying belt rubber material and preparation method and application thereof

An ionic liquid, rubber material technology, applied in conveyors, transportation and packaging, etc., can solve the problems of poor temperature resistance and heat insulation performance of rubber surface, reduced conveyor belt life, decreased tear resistance, etc. Adjustment, high continuous service life and strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

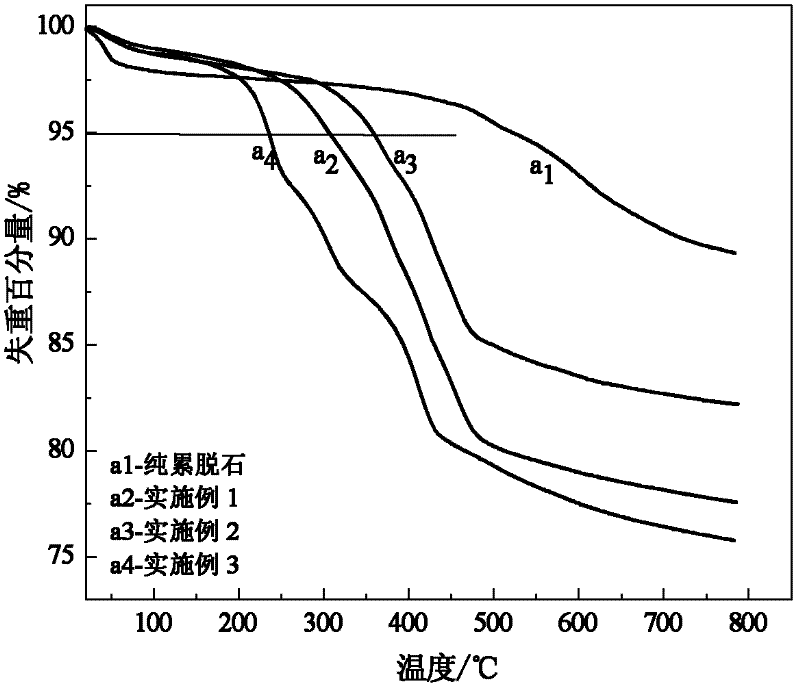

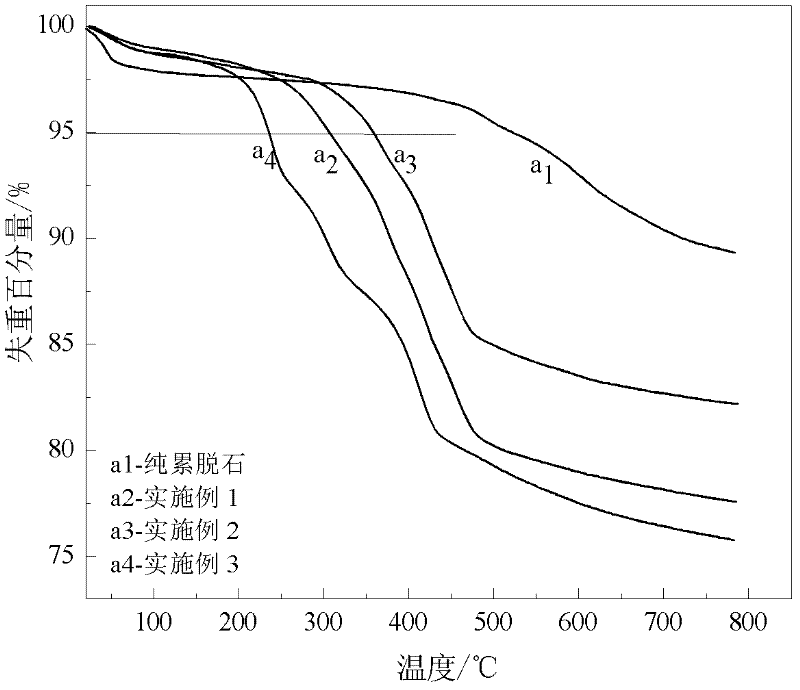

Examples

Embodiment 1

[0034] An ionic liquid type high temperature resistant conveyor belt rubber material, the components and parts by weight of each raw material are:

[0035] Rubber material: 80 parts;

[0036] DCP curing agent: 6 parts;

[0037] DM accelerator: 0.5 parts;

[0038] TT Accelerator: 1 part;

[0040] Stearic acid: 1 part;

[0041] RD antioxidant: 1 part;

[0042] BLE anti-aging agent: 0.5 parts;

[0043] TCP flame retardant: 6 parts;

[0044] Chlorinated paraffin: 2 parts;

[0045] Terpene resin: 3 parts;

[0046] Ancient Marron: 5 servings;

[0047] Carbon black: 50 parts;

[0048] No. 300 paraffin oil: 3 parts;

[0049] Sulfur: 0.5 parts;

[0050] Ionic liquid type phyllosilicate: 1 part.

[0051] The rubber material is a mixture of natural rubber, EPDM rubber and styrene-butadiene rubber, and its mass ratio is natural rubber: EPDM rubber: styrene-butadiene rubber = 4:2:1.

[0052] The ionic liquid is 1-tetradecyl-3-methylimidazolium br...

Embodiment 2

[0062] An ionic liquid type high temperature resistant conveyor belt rubber material, the components and parts by weight of each raw material are:

[0063] Rubber material: 100 parts;

[0064] DCP curing agent: 10 parts;

[0065] DM Accelerator: 2 parts;

[0066] TT Accelerator: 5 parts;

[0068] Stearic acid: 3 parts;

[0069] RD antioxidant: 3 parts;

[0070] BLE anti-aging agent: 1.5 parts;

[0071] TCP flame retardant: 12 parts;

[0072] Chlorinated paraffin: 5 parts;

[0073] Terpene resin: 8 parts;

[0074] Ancient Marron: 8 servings;

[0075] Carbon black: 90 parts;

[0076] No. 300 paraffin oil: 8 parts;

[0077] Sulfur: 1 part;

[0078] Ionic liquid type phyllosilicate: 10 parts.

[0079] The rubber material is a mixture of natural rubber, EPDM rubber and styrene-butadiene rubber, and its mass ratio is natural rubber: EPDM rubber: styrene-butadiene rubber = 8: 4: 1.

[0080] The ionic liquid is 1-octadecyl-3 methylimidazoli...

Embodiment 3

[0087] An ionic liquid type high temperature resistant conveyor belt rubber material is characterized in that the components and parts by weight of each raw material are:

[0088] Rubber material: 90 parts;

[0089] DCP curing agent: 8 parts;

[0090] DM Accelerator: 1 part;

[0091] TT Accelerator: 2 parts;

[0092] Zinc oxide: 8 parts;

[0093] Stearic acid: 2 parts;

[0094] RD antioxidant: 2 parts;

[0095] BLE anti-aging agent: 1 part;

[0096] TCP flame retardant: 10 parts;

[0097] Chlorinated paraffin: 3 parts;

[0098] Terpene resin: 5 parts;

[0099] Ancient Marron: 6 servings;

[0100] Carbon black: 70 parts;

[0101] No. 300 paraffin oil: 5 parts;

[0102] Sulfur: 0.75 parts;

[0103] Ionic liquid type phyllosilicate: 5 parts.

[0104] The rubber material is a mixture of natural rubber, EPDM rubber and styrene-butadiene rubber, and its mass ratio is natural rubber: EPDM rubber: styrene-butadiene rubber = 6:3:1. the

[0105] The ionic liquid is 1-tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com