Phase-change fire resistant conveyer belt

A conveyor belt, high temperature resistant technology, applied in the field of phase change and high temperature resistant conveyor belts, can solve the problems of shortened conveyor belt life, complex production process, poor temperature and heat insulation performance of the rubber surface, and achieve high continuous service life and production technology. Simple, heat-resistant temperature-adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

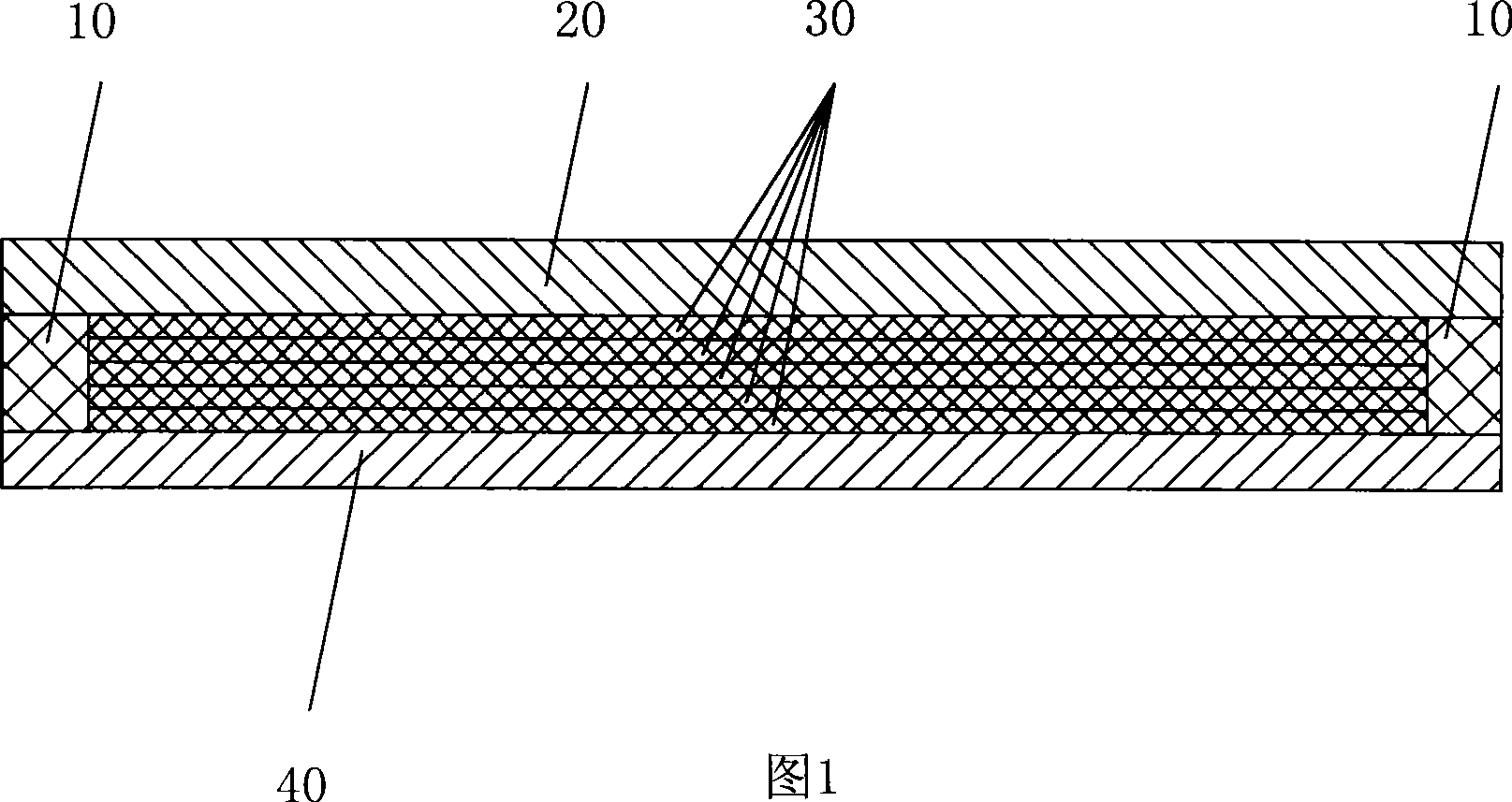

[0022] Referring to Fig. 1 : a phase-change high-temperature-resistant conveyor belt, the cross section of which is: an edge glue 10 is arranged at both ends of the fabric core layer 30, and a non-working surface glue 40 is arranged at the lower end of the edge glue 10 and the fabric core layer 30. The upper end of the side glue 10 and the fabric core layer 30 is provided with a working surface glue 20;

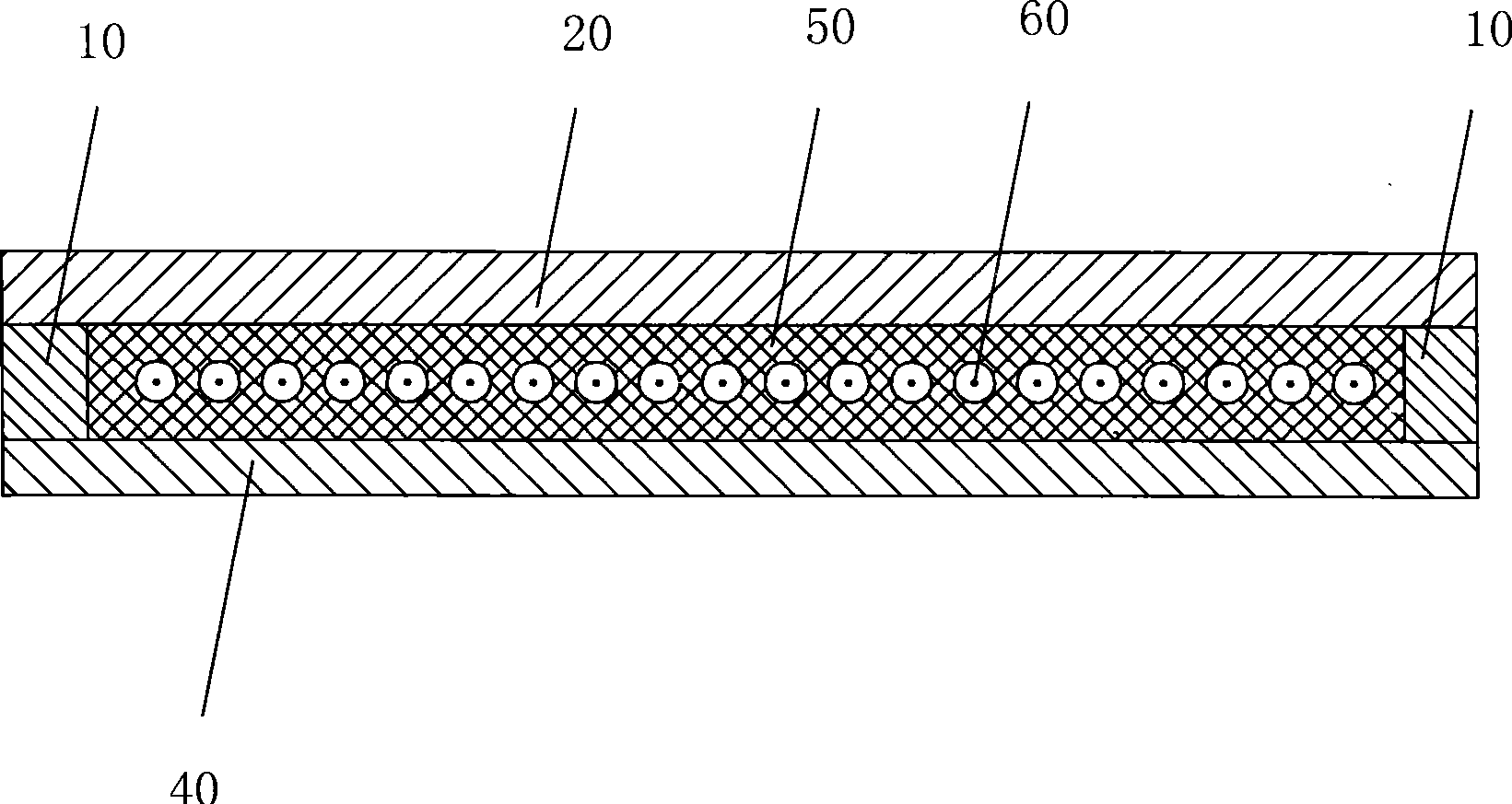

[0023] see figure 2 : a phase-change high-temperature-resistant conveyor belt, the cross section of which is: edge rubber 10 is arranged at both ends of the steel wire rope layer, and the steel wire rope layer is wrapped with a core rubber 50 in a space other than the steel wire rope 60, and the edge glue 10 and the steel wire rope The lower end of the layer is provided with a non-working surface glue 40, and the upper end of the side glue 10 and the wire rope layer is provided with a working surface glue 20;

[0024] Among them, non-working surface rubber, edge rubber, core...

Embodiment 2

[0032] Structure of the present invention is identical with embodiment 1, and its difference is:

[0033] A phase-change high-temperature-resistant conveyor belt, whose non-working surface rubber, edge rubber, core rubber and working surface rubber are mixed by the following ingredients and parts by weight: rubber material: 100 parts; DCP vulcanizing agent: 8 parts ;DM accelerator: 1 part; TT accelerator: 1 part; Zinc oxide: 7 parts; Stearic acid: 2 parts; RD antioxidant: 2 parts; BLE antioxidant: 1 part; TCP flame retardant: 8 parts; Chlorinated paraffin: 3 parts; Terpene resin: 6 parts; Coomalon: 5 parts; Carbon black: 80 parts; No. 300 paraffin oil: 4 parts; Sulfur: 1 part; Nano silicon / alcohol phase change substance: 20 parts.

[0034] The nano-silicon / alcohol phase change material is nano-silicon dioxide / polyethylene glycol / epoxy resin. The specific production process is to dissolve polyethylene glycol in ethanol, add tetraethyl orthosilicate, and Mix evenly, add hydroch...

Embodiment 3

[0041] Structure of the present invention is identical with embodiment 1, and its difference is:

[0042] A phase-change high-temperature-resistant conveyor belt, whose non-working surface rubber, edge rubber, core rubber and working surface rubber are mixed by the following ingredients and parts by weight: rubber material: 100 parts; DCP vulcanizing agent: 8 parts ;DM accelerator: 1 part; TT accelerator: 1 part; Zinc oxide: 7 parts; Stearic acid: 2 parts; RD antioxidant: 2 parts; BLE antioxidant: 1 part; TCP flame retardant: 8 parts; Chlorinated paraffin: 3 parts; Terpene resin: 6 parts; Coomalon: 5 parts; Carbon black: 80 parts; No. 300 paraffin oil: 4 parts; Sulfur: 1 part; Nano silicon / alcohol phase change substance: 15 parts.

[0043] The nano-silicon / alcohol phase change material is nano-silicon dioxide / polyethylene glycol / epoxy resin. The specific production process is to dissolve polyethylene glycol in ethanol, add tetraethyl orthosilicate, and Mix evenly, add hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com