Wideband underwater acoustic absorption and transmission material and preparation method thereof

A sound-transmitting material and wide-band technology, applied in the field of underwater acoustic materials, can solve problems such as single function, and achieve the effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The parts by weight of the various components of the material are shown in Table 2 in the present embodiment:

[0030] Table 2 The parts by weight of the various components of the material of embodiment 1

[0031] Material

Sound-permeable layer (parts)

Sound-absorbing layer (parts)

Chlorobutyl rubber

100

100

High wear-resistant carbon black

40

20

10

10

5

5

20

20

10

10

Antiager D

1.5

1.5

Accelerator TMTD

1

1

2

2

-

2

[0032] The preparation method is as follows:

[0033] Mastication: Firstly, the chlorinated butyl rubber is thinned and masticated on an open mill for 5 minutes. After mastication, it is parked for 24 hours for mixing.

[0034] Mixing of the sound-transmitting layer: The mixing of ru...

Embodiment 2

[0044] Others are the same as embodiment 1. But the parts by weight of the various components of the material are shown in Table 3:

[0045] Table 3 The parts by weight of the various components of the material of embodiment 2

[0046] Material

[0047] iron powder

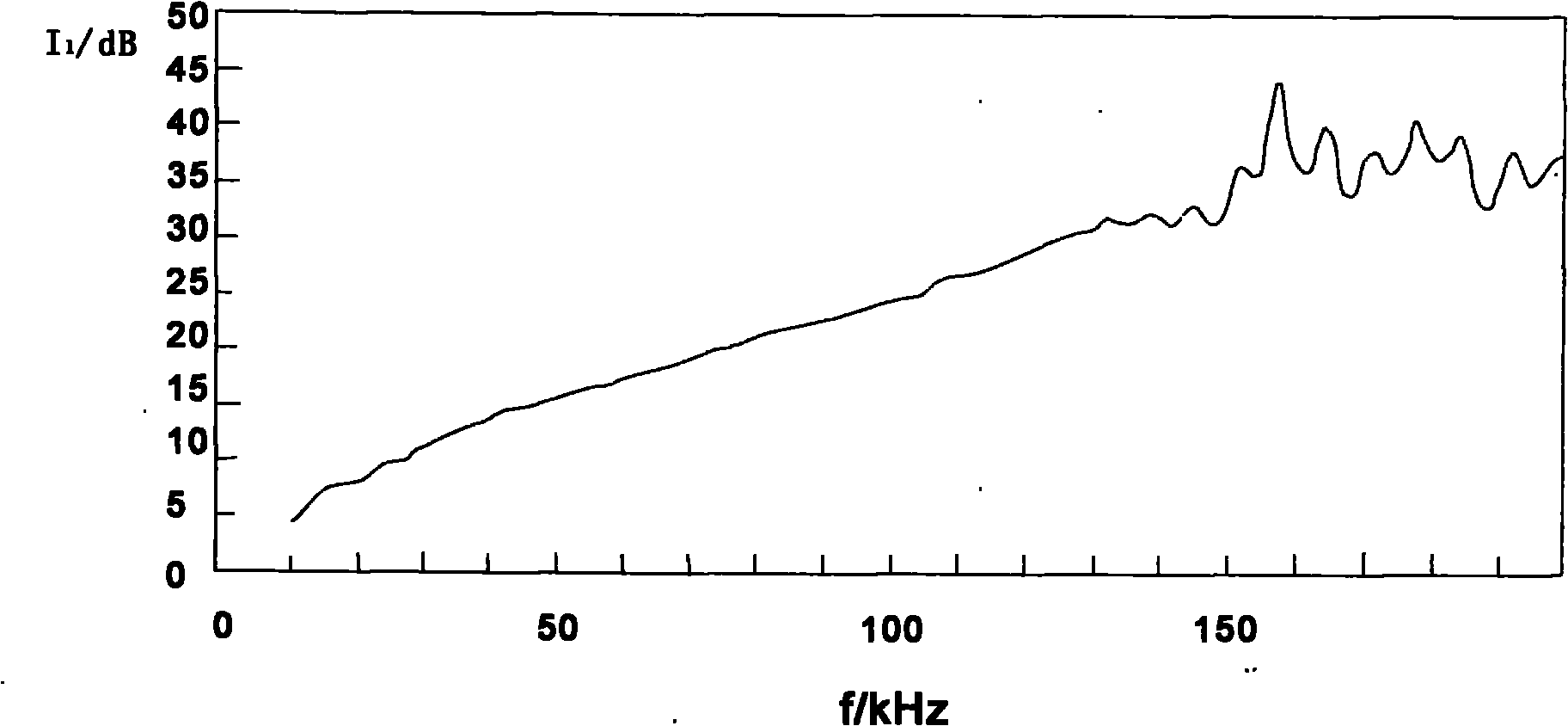

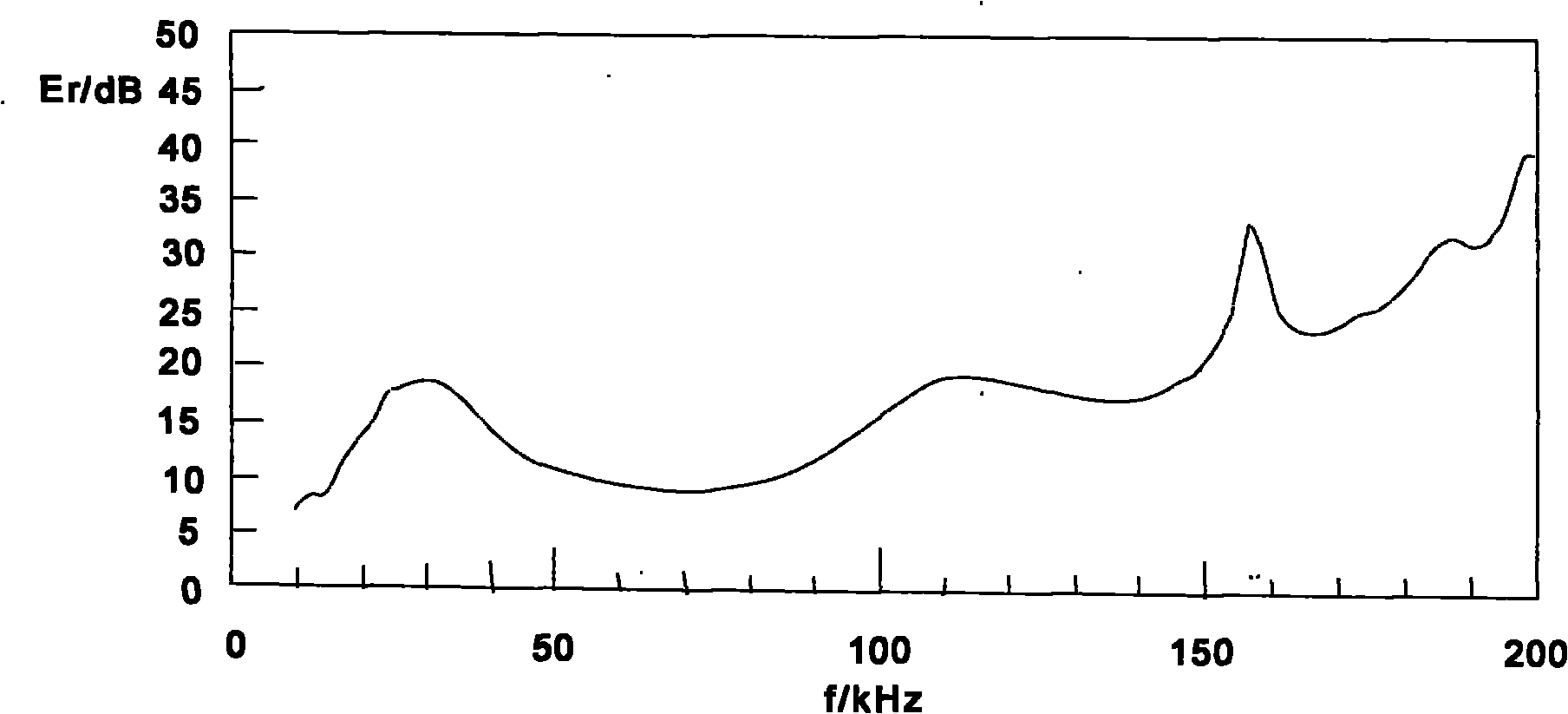

[0048] According to the test method stipulated in GB / T 14369-1993, the acoustic performance of the material is tested in the anechoic pool, and the results are shown in Figure 4 and Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com