Room temperature/low temperature vulcanized chloroprene rubber sizing material

A technology for vulcanizing chloroprene rubber and rubber compound, applied in the rubber field, can solve problems such as slow vulcanization speed and easy scorch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

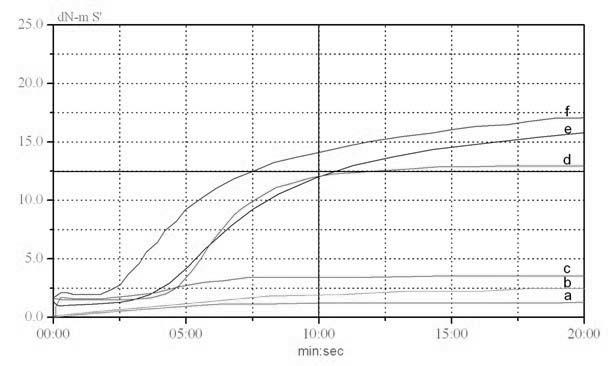

Image

Examples

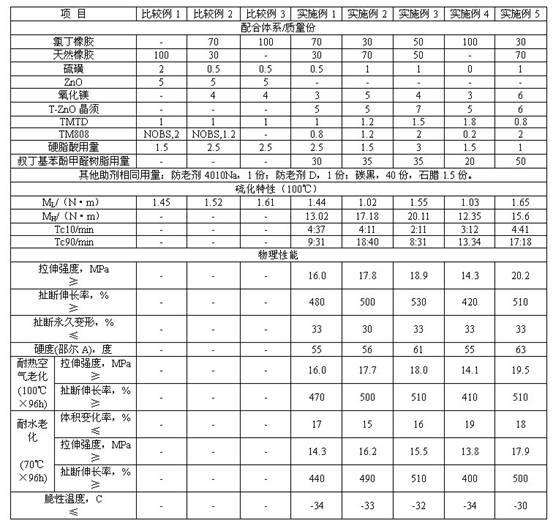

Embodiment 1

[0035] Compared with Example 4, the physical and mechanical properties of chloroprene rubber and natural rubber are significantly improved; and the increase in the amount of accelerator TM808 and tert-butylphenol formaldehyde resin is beneficial to the improvement of physical and mechanical properties.

Embodiment 2

[0036] Embodiment 2 is compared with embodiment 5, and the increase positive sulfur time of T-ZnO whisker delays; But the reduction of the consumption of TM808 and tert-butylphenol formaldehyde resin makes its physical and mechanical properties reduce to some extent, and its rule is as implementing The comparison of example 1 and embodiment 4.

Embodiment 3

[0037] Embodiment 3 compares with embodiment 1, embodiment 2, embodiment 4 and embodiment 5, and the consumption of TM808 is bigger for the physical and mechanical properties of sizing material, followed by the influence of T-ZnO whisker; Comparative embodiment 3 It can be seen from Example 5 that the larger the dosage of T-ZnO whiskers is not the better, it has a suitable dosage.

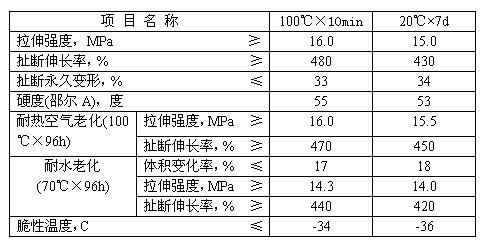

[0038] The vulcanization and performance indicators of the rubber compound in Example 1 at 100°C×10 minutes and 20°C×7 days (room temperature) are shown in Table 2, which shows that the rubber compound in the embodiment can fully meet the requirements of large-scale products at room temperature for more than 7 days. performance requirements.

[0039]It can be seen from Table 1 and Table 2 that the rubber compound of the present invention exhibits better room temperature / low temperature vulcanization characteristics, and has good scorch performance, that is, Tc10 / min is appropriate, and the normal v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com