White carbon black rubber composition capable of prolonging scorching time, mixing method of white carbon black rubber composition and tire

A technology for rubber composition and scorch time, which is applied to the white carbon black rubber composition and its mixing method and the field of tires, can solve the problems of shortened scorch time and poor processing performance of the rubber composition, and achieves inhibition of mercapto reaction. The effect of reactivity, viscosity reduction, and improvement of rubber scorch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

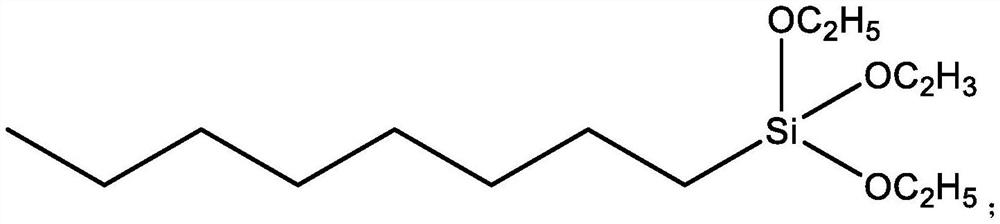

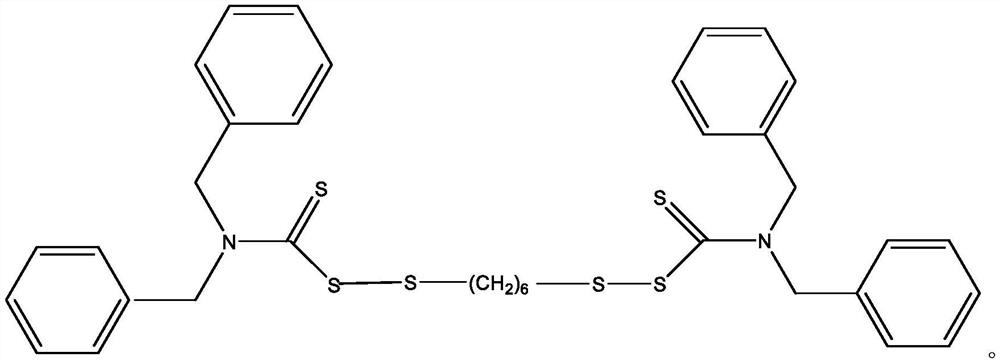

Method used

Image

Examples

Embodiment 1-3

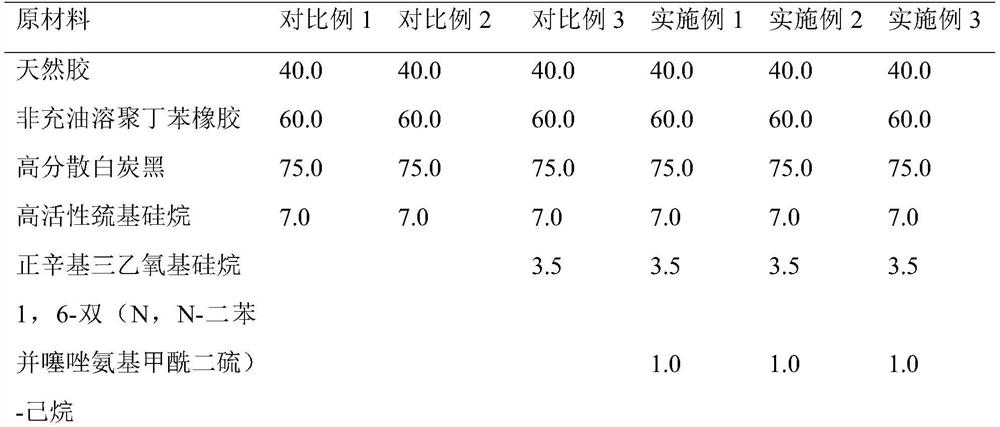

[0033] The processes of Examples 1-3, Comparative Example 2, and Comparative Example 3 are as follows: a two-stage mixing process and a three-stage final refining process are adopted.

[0034] Examples 1-3, Comparative Example 2, and Comparative Example 3 were mixed in one stage: a German Krupp GK320-E550 series internal mixer was used for mixing. The specific process steps of the mixing process are shown in Table 3.

[0035] Table 3 Embodiment 1-3, comparative example 2, comparative example 3 one stage mixing process

[0036]

[0037]

Embodiment 1

[0038] Example 1, Comparative Example 2, and Comparative Example 3 Two-stage mixing: German Krupp GK320-E550 series internal mixer was used for mixing. The specific process steps of the mixing process are shown in Table 4.

Embodiment 1-3、 comparative example 2

[0039] Embodiment 1-3, comparative example 2, comparative example 3 two-stage mixing process

[0040]

[0041] Embodiment 1, Comparative Example 2, Comparative Example 3 final refining section process: consistent with the comparative example final refining section process, the difference is the addition of 1,6-bis(N,N-dibenzothiazolecarbamoyl disulfide) - hexane;

[0042] The comparative examples and the examples are compared with the rheological properties, physical and mechanical properties, dynamic properties, and processing properties respectively, and obtain two different final refining processes and the impact on the performance of the rubber composition after adding auxiliary agents:

[0043] Table 5 Embodiment 1-3 and comparative example 1, comparative example 2, comparative example 3 rheological and processing characteristics contrast

[0044]

[0045] It can be seen from Table 5 that only through the adjustment of the mixing process in Comparative Example 2, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com