Rubber speed bump and preparation method thereof

A speed bump and rubber technology, which is applied in the field of rubber speed bumps and its preparation, can solve the problems of fast aging process of speed bumps and short service life of speed bumps, and achieve the effects of increasing strength, preventing thermal oxygen aging, and preventing copper damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

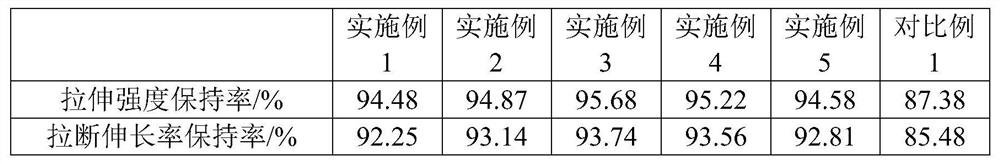

Examples

preparation example Construction

[0044] A method for preparing a rubber speed bump, comprising the steps of:

[0045] Step 1: According to parts by weight, weigh styrene-butadiene rubber, sulfur, vulcanization accelerator, zinc oxide, stearic acid, calcium carbonate, white carbon black, modified 2,2'-thiobis(4-methyl-6 -tert-butylphenol), 2-mercaptobenzimidazole, microcrystalline wax, UV absorber, softener, dispersant, plasticizer;

[0046] Step 2: Put all the raw materials in a mixer and stir them evenly, then pour them into the mold, then put them in the extruder, and extrude them at an extrusion temperature of 170°C and an extrusion pressure of 20MPa to obtain the green body of the speed bump material , and finally put it into a calender, press out the concave-convex pattern at an extrusion temperature of 70°C, cool naturally to room temperature, and then discharge.

[0047] The preparation method of the modified 2,2'-thiobis(4-methyl-6-tert-butylphenol) is described in detail below.

[0048] A preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com