Light high-strength brominated butyl rubber gas tightness material and preparation method and application thereof

A technology of bromobutyl rubber and air tightness, which is applied in the field of material synthesis and processing, and organic chemical synthesis, can solve the problems of reducing the service life of rubber, high cost of graphene preparation, and destroying the air tightness of rubber, so as to achieve enhanced air tightness. Tightness, reduce dust pollution, reduce the effect of density and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The ratio of raw materials is: including 100 parts of bromobutyl rubber, 1.5 parts of modified graphene oxide, 6 parts of zinc oxide, 1.5 parts of stearic acid, 0.4 parts of accelerator TMTD and 0.3 parts of accelerator DM;

[0032] The preparation method is:

[0033] The first step: preparation of modified graphene oxide

[0034] Weigh graphene oxide and octadecylamine of equal mass, then place graphene oxide in a beaker, add water and disperse with 100W power ultrasonic vibration for 3 hours to obtain a uniform dispersion; fully dissolve octadecylamine in dimethylformamide ( Generally, 1g of octadecylamine needs 100ml of dimethylformamide; transfer the two liquids obtained above to a three-neck flask and react at reflux for 22h at 100°C, vacuum filter the product, and wash it with ethanol Filter 5 times, place in a vacuum drying oven at 60°C and dry to constant weight to obtain modified graphene oxide;

[0035] The second step: disperse the modified graphene oxide i...

Embodiment 5

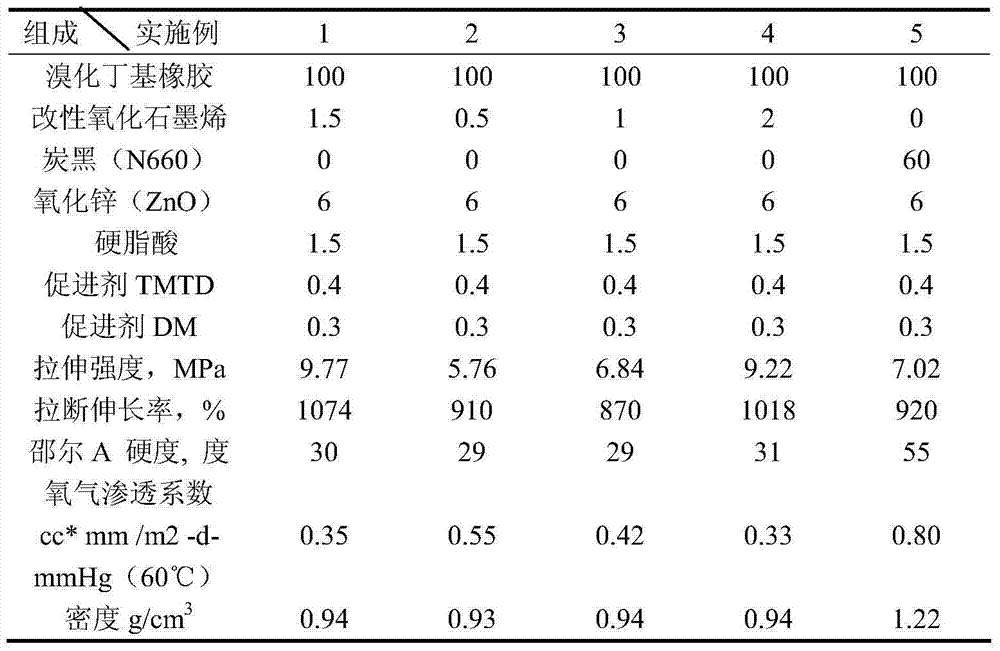

[0050] It can be seen from the table that compared with traditional reinforcing agents, the use of modified graphene oxide to reinforce bromobutyl rubber can effectively reduce the density and hardness of rubber, improve the air tightness of rubber and reduce dust pollution. . Under the same air tightness requirements, the amount of rubber used can be greatly reduced, thereby reducing product weight and cost.

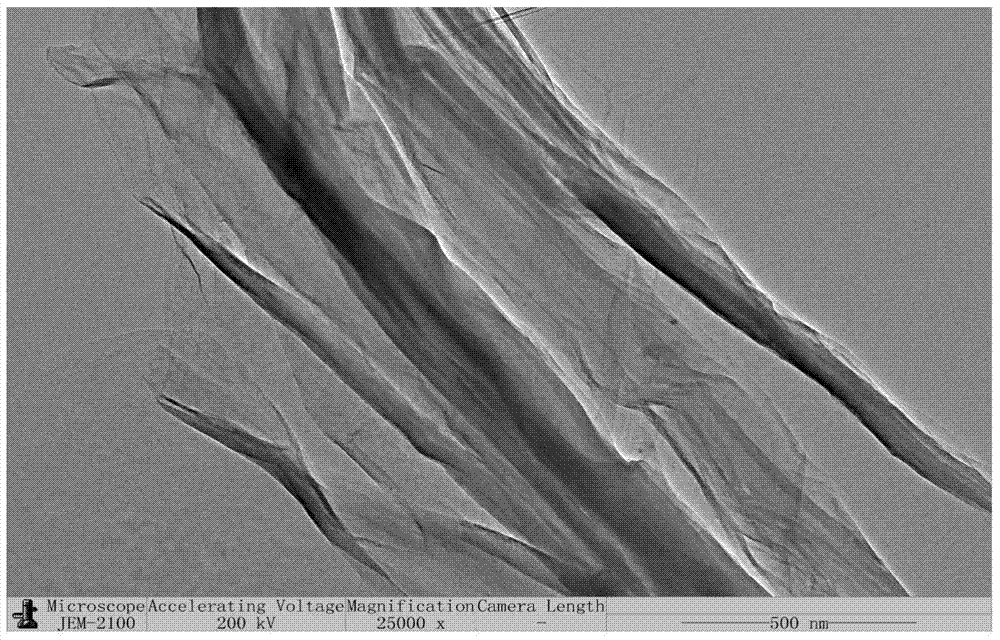

[0051] figure 1 It is the monolithic structure diagram of graphene oxide dispersed in N,N-dimethylformamide under the transmission electron microscope; from figure 1 The physical form of exfoliated graphene oxide can be seen in the figure, and graphene oxide dispersed in N,N-dimethylformamide (DMF for short) can be observed to present stacked sheets with curled edges. It can also be observed that certain sites exhibit a wrinkled morphology, or folds, which lowers the surface energy and stabilizes it.

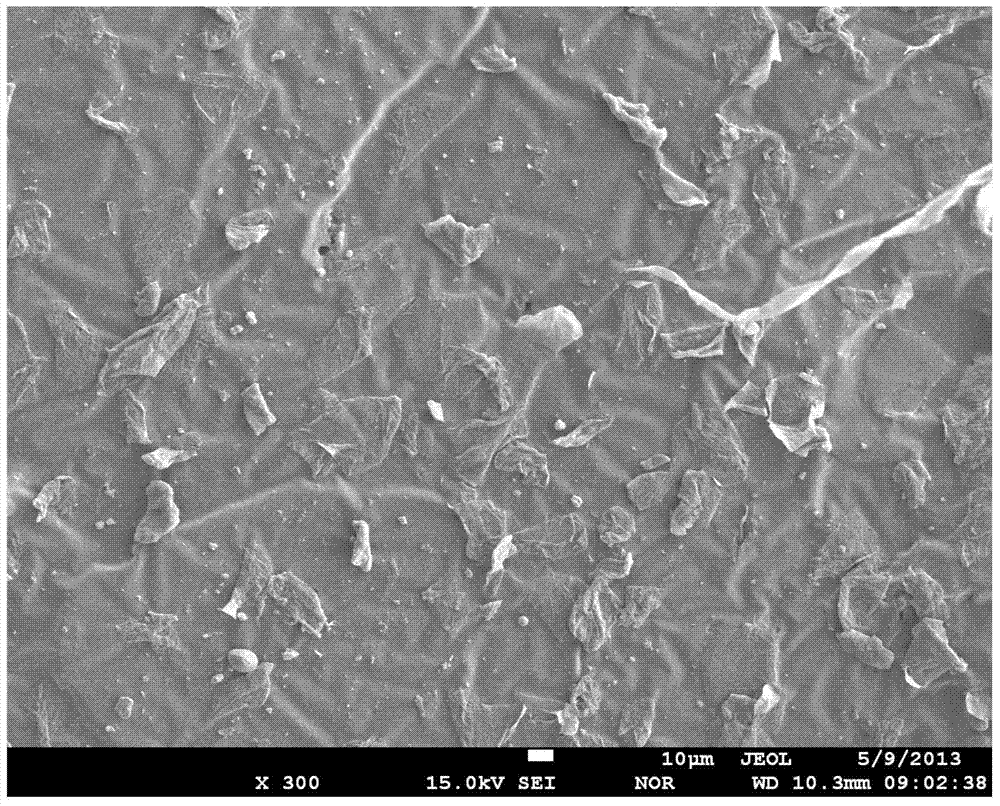

[0052] figure 2 It is the distribution figure of 1.5 parts of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com