Cable jacket rubber and preparation method

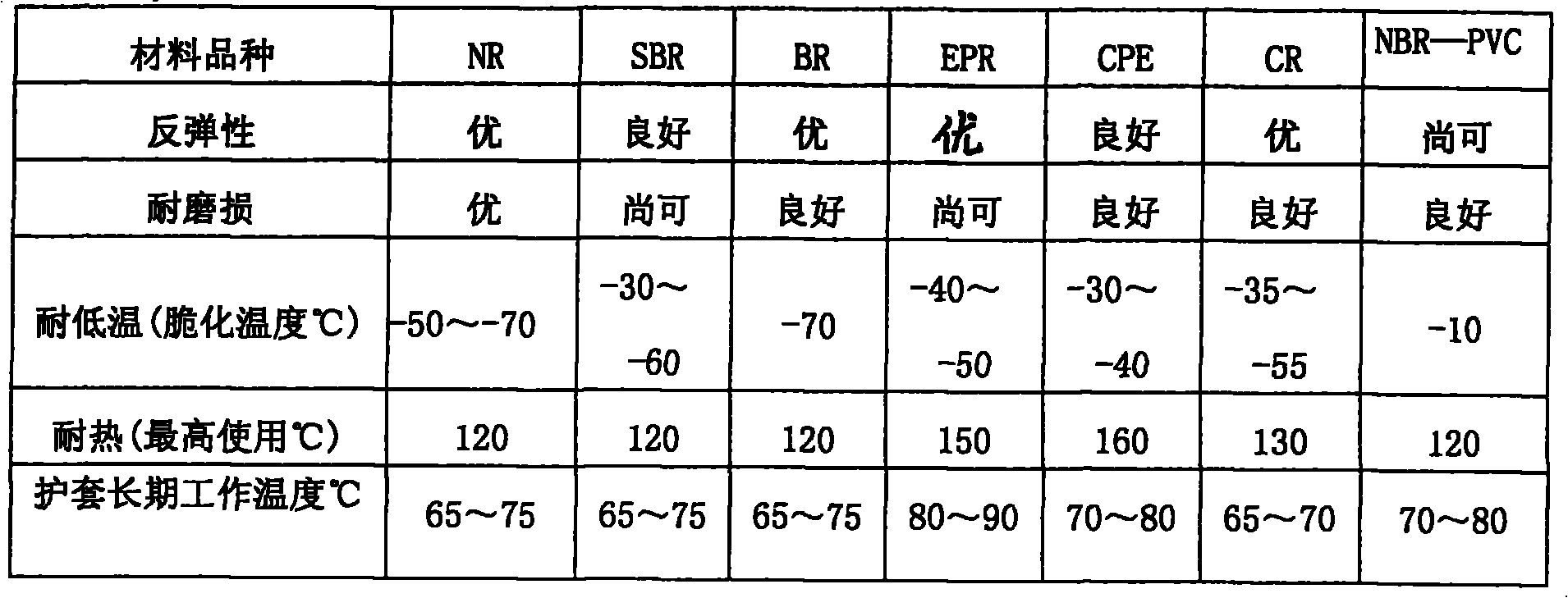

A rubber and sheath technology, applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problem that the wear resistance and low-temperature elasticity of the support rubber cannot meet the requirements of the rubber used for the cable sheath, the mechanical and physical properties are not fully considered, and the dynamic Cold-resistant products and other problems, to achieve the effects of slow scorch, good tearing, and short vulcanization bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

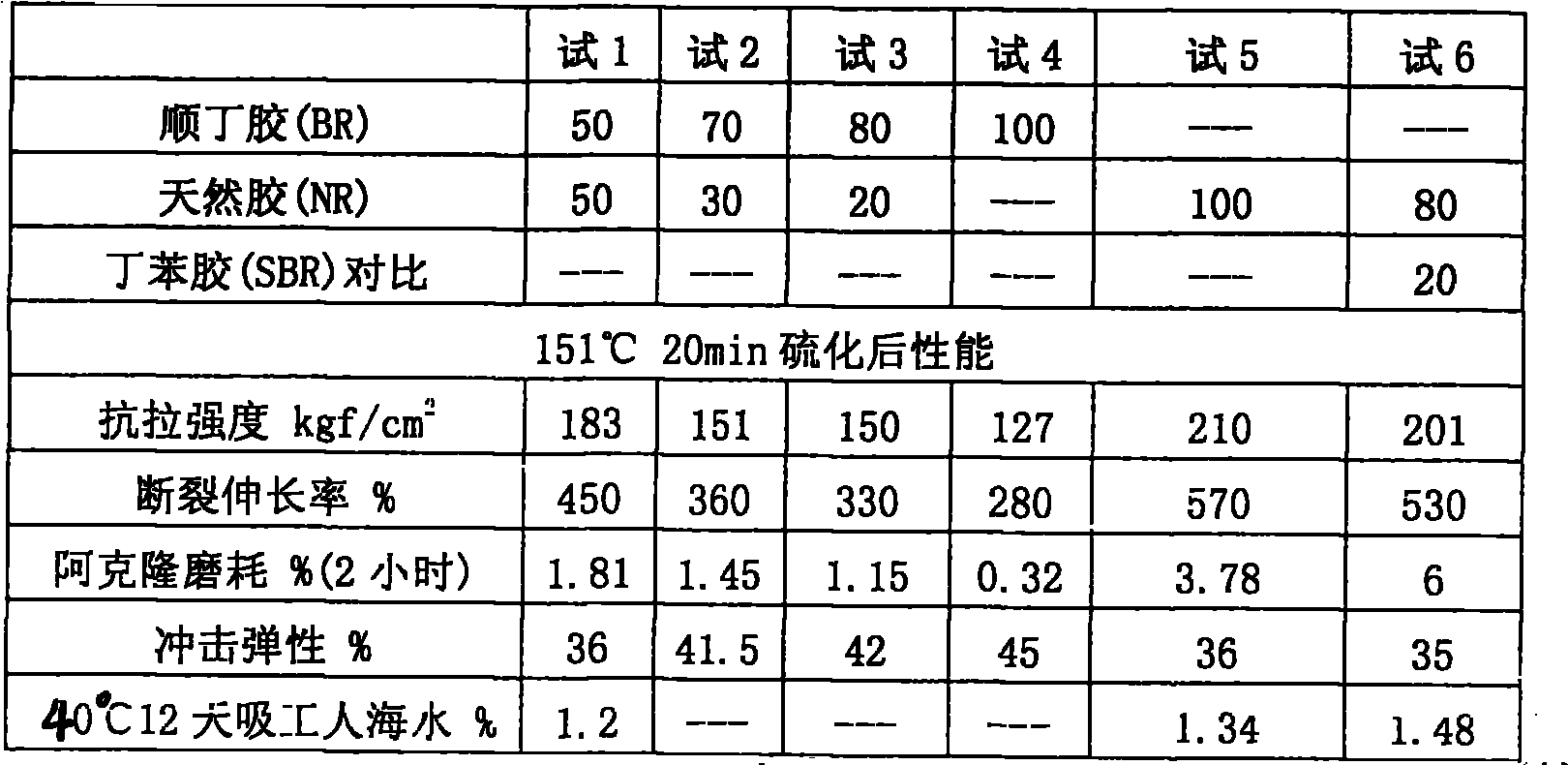

Examples

Embodiment

[0017] Embodiment: According to the ratio of the embodiment in Table 4, first place the purchased natural rubber (about 0.3 Vickers plasticity) in an open rubber mixer or internal mixer for mastication, and the temperature of the open mastication roller is below 80°C, The temperature of the machine is below 100°C, so that the Vickers plasticity of natural rubber can reach 0.60-0.75. Put masticated natural rubber and butadiene rubber into the mixer and mix until uniform. The rest is carried out according to the usual rubber mixing process (open process or compacted process), such as the compacted process: first add 1 / 2 of the reinforcing agent (such as high wear-resistant carbon black (HSCB)) and filler (such as carbonic acid Calcium, clay, talcum powder, etc.), add softener (such as stearic acid, paraffin) and knead for 1.5-2.0 minutes, the temperature is below 100 ℃, after mixing evenly, add the remaining reinforcing agent (such as gas-mixed carbon black) And filler, add ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com