Self-lubricating material for filter sealing piece and preparation method thereof

A technology of self-lubricating materials and seals, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that the smoothness cannot meet the requirements of automatic production lines, reduce the surface friction coefficient of rubber seals, etc., and achieve improved vulcanization and demoulding. Performance, uniform appearance, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

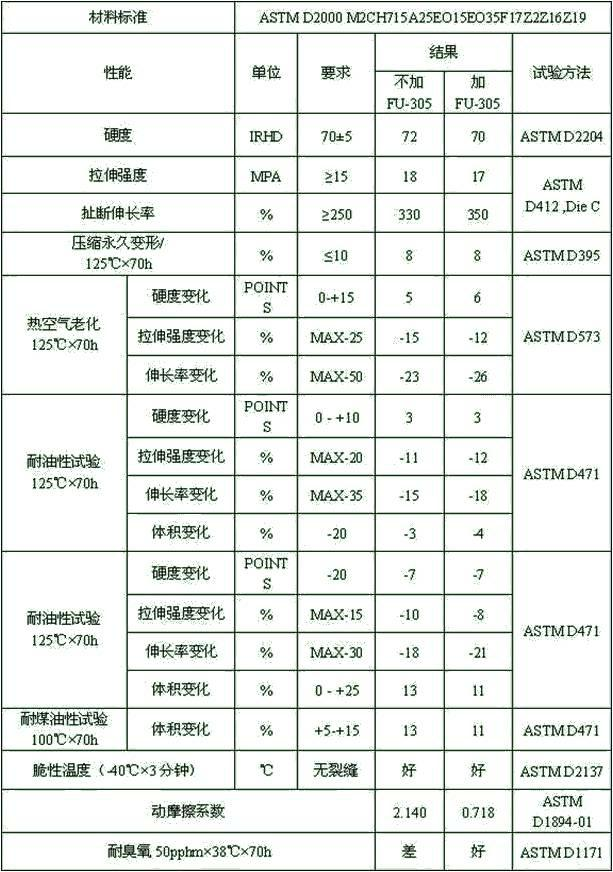

[0046] A self-lubricating material for a filter seal of the present embodiment is composed of components in weight percentage in Table 1:

[0047] Table 1 Components and percentages of self-lubricating materials for filter seals in Example 1

[0048] Raw material name Percent content / % Nitrile rubber 45 High wear-resistant carbon black 25 semi-reinforcing carbon black 13 Zinc oxide 5 stearic acid 0.8 Antiaging agent 4,4'-bis(phenylisopropyl)diphenylamine 1.3 Antiaging agent 2-mercaptomethylbenzimidazole zinc salt 0.8 sulfur 0.2 Accelerator DTDM 1.5 Accelerator TT 0.8 Accelerator CZ 0.8 Bis[2-(2-butoxyethoxy)ethyl adipate] (TP-95) 4.5 Fluorine Wax FU-305 1.3

[0049]The fluorine wax FU-305 in this implementation is produced by Shanghai Jingyi Rubber Technology Co., Ltd. The main performance parameters are: the melting point is 72~76°C; the flash point is 210°C. Bis[2-(2-butoxyethoxy)et...

Embodiment 2

[0060] A self-lubricating material for a filter seal of the present embodiment is composed of components in weight percent in Table 2:

[0061] Table 2 Components and percentages of self-lubricating materials for filter seals in Example 2

[0062] Raw material name Percent content / % Nitrile rubber 44 High wear-resistant carbon black 22.2 semi-reinforcing carbon black 15 Zinc oxide 5 stearic acid 0.5 Antiaging agent 4,4'-bis(phenylisopropyl)diphenylamine 1 Antiaging agent 2-mercaptomethylbenzimidazole zinc salt 0.5 sulfur 0.3 Accelerator DTDM 2 Accelerator TT 1 Accelerator CZ 1 Bis[2-(2-butoxyethoxy)ethyl adipate] (TP-95) 6 Fluorine Wax FU-305 1.5

[0063] The fluorine wax FU-305 in this implementation is produced by Shanghai Jingyi Rubber Technology Co., Ltd. The main performance parameters are: the melting point is 72~76°C; the flash point is 210°C. Bis[2-(2-butoxyethoxy)ethyl adipat...

Embodiment 3

[0072] A self-lubricating material for a filter seal of the present embodiment is composed of components in weight percent in Table 3:

[0073] Table 3 Components and percentages of self-lubricating materials for filter seals in Example 3

[0074] Raw material name Percent content / % Nitrile rubber 45 High wear-resistant carbon black 25 semi-reinforcing carbon black 15 Zinc oxide 5 stearic acid 0.8 Antiaging agent 4,4'-bis(phenylisopropyl)diphenylamine 1.3 Antiaging agent 2-mercaptomethylbenzimidazole zinc salt 0.8 sulfur 0.1 Accelerator DTDM 2 Accelerator TT 0.5 Accelerator CZ 0.5 Bis[2-(2-butoxyethoxy)ethyl adipate] (TP-95) 3 Fluorine Wax FU-305 1

[0075] The fluorine wax FU-305 in this implementation is produced by Shanghai Jingyi Rubber Technology Co., Ltd. The main performance parameters are: the melting point is 72~76°C; the flash point is 210°C. Bis[2-(2-butoxyethoxy)ethyl adip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com