Nitrile rubber for extra-high voltage large-scale oil-immersed type transformer

A technology for nitrile rubber and transformers, applied in the rubber field, can solve the problems of normal operation of transformers, unsafe transformers, transformer breakdowns, etc., to solve the problems of gas production and insulation performance decline, maintenance and operation safety, and oil aging performance improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

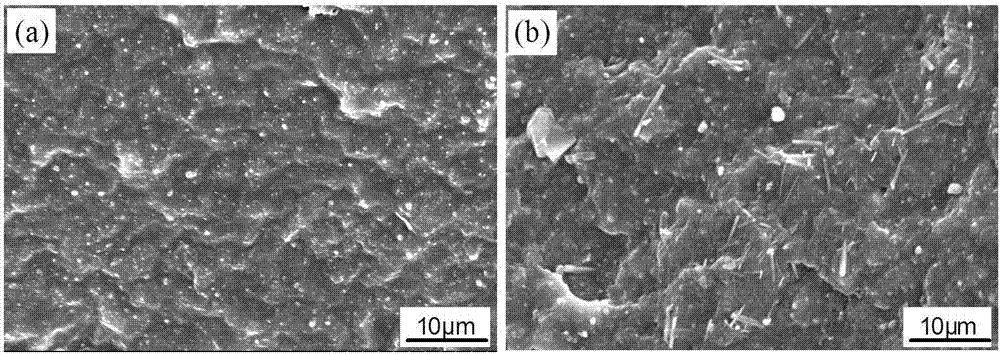

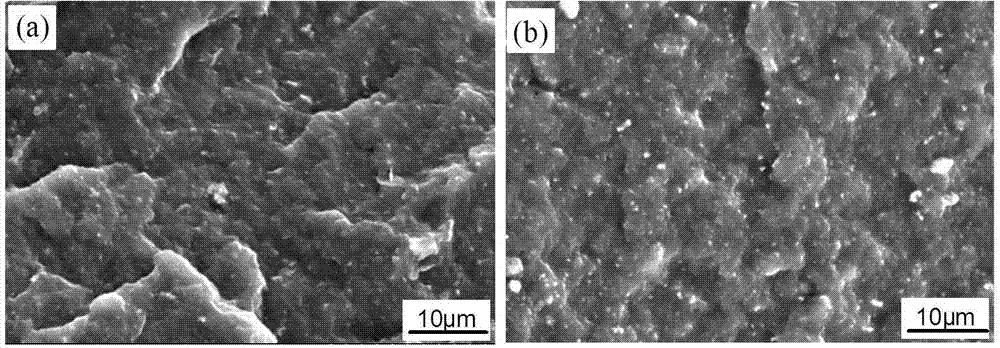

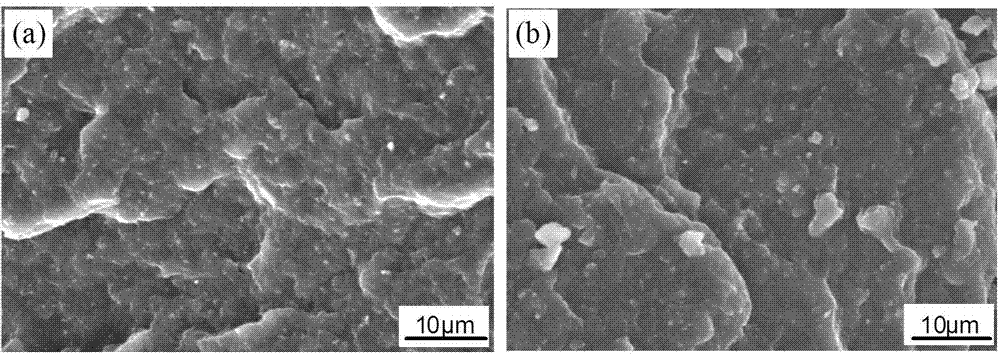

Image

Examples

Embodiment 1

[0036] In terms of mass fraction: 100 parts of nitrile rubber NBR, 0.1 part of stearic acid, 10 parts of carbon black, 10 parts of spray carbon black, 1 part of zinc oxide, 0.1 part of vulcanizing agent DTDM, and 0.1 part of vulcanizing agent TETD 0.1 part, 0.1 part of vulcanizing agent TMTD, 0.1 part of accelerator CZ, 0 part of anti-aging agent RD, 0.1 part of anti-aging agent MB, 0.1 part of anti-aging agent 4010, 1 part of paraffin wax, 1 part of Coumaron The dosage of octyl ester is 5 parts.

Embodiment 2

[0038] In terms of mass fraction: 100 parts of nitrile rubber NBR, 20 parts of stearic acid, 80 parts of carbon black, 80 parts of spray carbon black, 30 parts of zinc oxide, 20 parts of vulcanizing agent DTDM, and 20 parts of vulcanizing agent TETD 20. The amount of vulcanizing agent TMTD is 20 parts, the amount of accelerator CZ is 20 parts, the amount of anti-aging agent RD is 20 parts, the amount of anti-aging agent MB is 20 parts, the amount of anti-aging agent 4010 is 20 parts, the amount of paraffin is 20 parts, the amount of coumarone is 30 parts, sebacin The amount of ester is 50 parts.

Embodiment 3

[0040] In terms of mass fraction: 100 parts of nitrile rubber NBR, 1 part of stearic acid, 35 parts of carbon black, 20 parts of spray carbon black, 5 parts of zinc oxide, 2 parts of vulcanizing agent DTDM, and 2 parts of vulcanizing agent TETD 0.87, vulcanizing agent TMTD dosage 0.87, accelerator CZ dosage 1.45 parts, antioxidant RD dosage 1.5 parts, antioxidant MB dosage 1 part, antioxidant 4010 dosage 1 part, paraffin dosage 1 part, coumarone dosage 5 parts, sebacin The amount of ester is 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com