Preparation method of low-salt sauce

A low-salt, soy sauce technology, applied in food preparation, food science, application, etc., can solve the problems of soy sauce gas production, insufficient sauce flavor, high cost, etc., to extend the shelf life and solve the effect of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

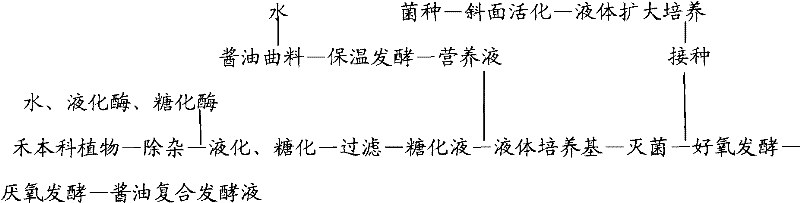

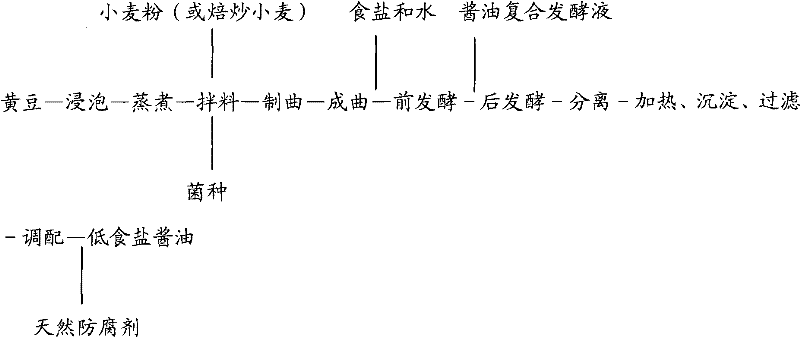

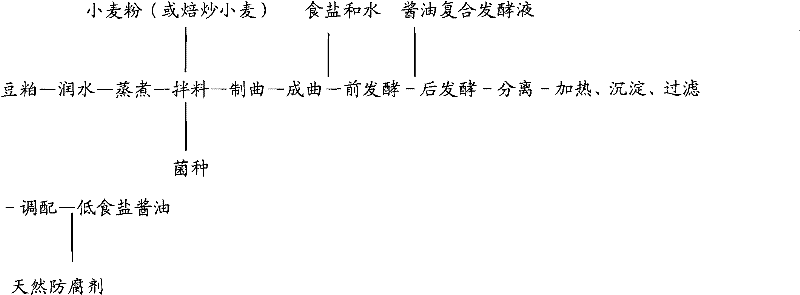

Method used

Image

Examples

preparation Embodiment 1

[0039] (1) The raw material accounts for 20% (rice:wheat = 1:1), add 80% (in total) of water, mix and undergo enzymatic liquefaction and saccharification, and obtain a saccharification solution after filtration, the sugar concentration of which is 20% ; Among them, the liquefaction enzyme is selected from high temperature resistant α-amylase (Novozymes China), and the glucoamylase is Suhong brand GAII (Novozymes China);

[0040] (2) Use soybean meal and wheat flour as raw materials to make koji according to the conventional soy sauce koji making method, then mix the koji and water at a weight ratio of 1:0.8, heat and ferment at 40°C for 7 hours, and then add warm water (50°C) to mix Finally, extract the amino acid polypeptide nutrient solution equivalent to the koji material;

[0041] (3) Mix 99 parts of the saccharification solution and 1 part of the amino acid polypeptide nutrient solution by volume to obtain a liquid medium, the pH value of which is 5.0, place it in a ferme...

preparation Embodiment 2

[0046] (1) Raw materials account for 20% (sorghum: rice = 6:4), add 80% (in total) of water, mix and undergo enzymatic liquefaction and saccharification, and obtain a saccharification solution after filtration, with a sugar concentration of 18% ; Among them, the liquefaction enzyme is selected from high temperature resistant α-amylase (Novozymes China), and the glucoamylase is Suhong brand GAII (Novozymes China);

[0047](2) using soybeans and wheat flour as raw materials to prepare koji according to the conventional soy sauce koji making method, then mixing koji and water in a weight ratio of 1:1.5, and fermenting at 50° C. for 10 hours to obtain amino acid polypeptide nutrient solution;

[0048] (3) Mix 98 parts of the saccharification solution and 2 parts of the amino acid polypeptide nutrient solution by volume to obtain a liquid medium, the pH value of which is 5.0, place it in a fermenter, sterilize it, and cool it to 30°C;

[0049] (4) Alcoholic yeast (CICC 1208) and ar...

preparation Embodiment 3

[0053] (1) Raw materials account for 20% (sorghum: rice = 6:4), add 80% (in total) of water, mix and undergo enzymatic liquefaction and saccharification, and obtain a saccharification solution after filtration, with a sugar concentration of 18% ; Among them, the liquefaction enzyme is selected from high temperature resistant α-amylase (Novozymes China), and the glucoamylase is Suhong brand GAII (Novozymes China);

[0054] (2) using soybeans and wheat flour as raw materials to prepare koji according to the conventional soy sauce koji making method, then mixing koji and water in a weight ratio of 1:1.5, and fermenting at 50° C. for 10 hours to obtain amino acid polypeptide nutrient solution;

[0055] (3) Mix 98.5 parts of saccharification solution and 1.5 parts of amino acid polypeptide nutrient solution by volume to obtain a liquid culture medium, the pH value of which is 4.85, place in a fermenter, sterilize, and cool to 30°C;

[0056] (4) Alcoholic yeast (CICC 1208) and aroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com