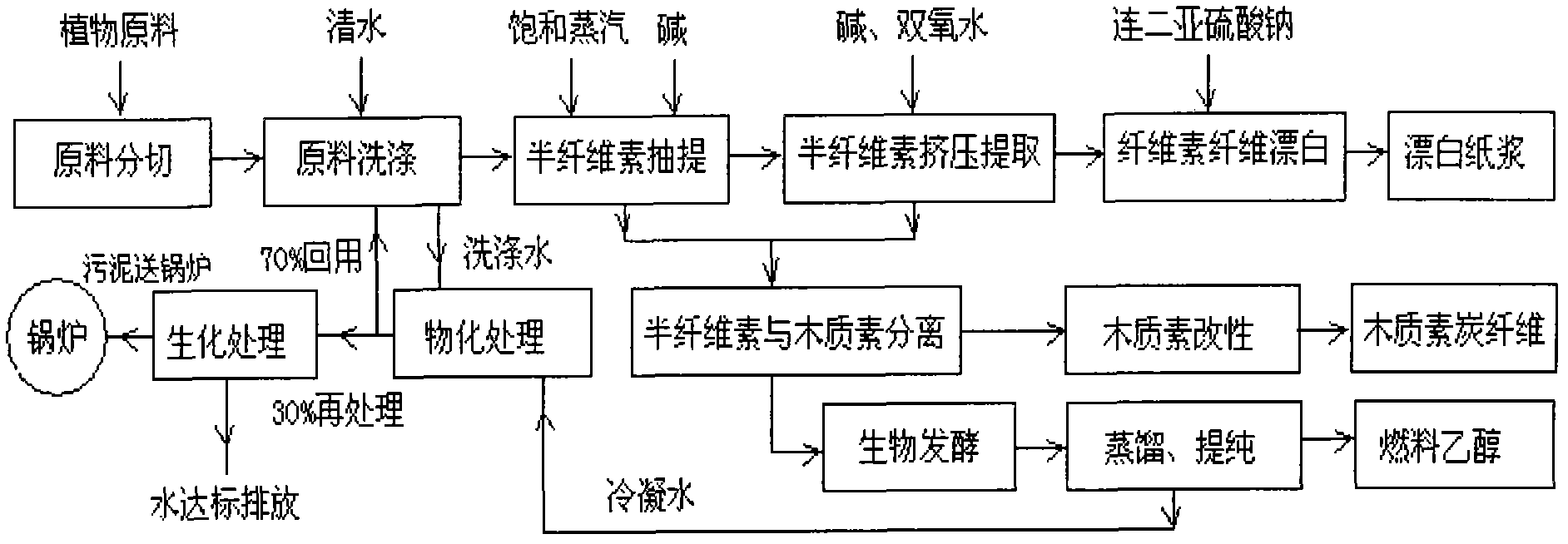

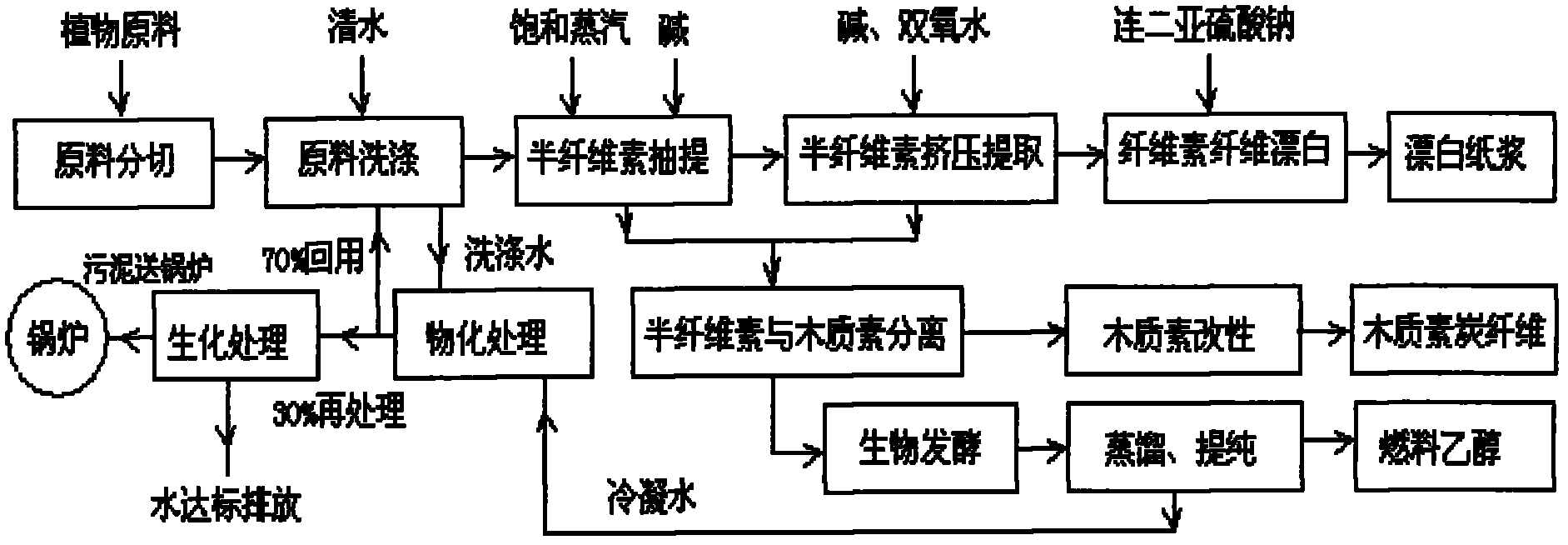

Preparation method for co-producing bleached paper pulp, lignin carbon fibers and fuel ethanol

A technology of lignin carbon and fuel ethanol, which is applied in the co-production of bleached pulp, fuel ethanol, and lignin carbon fiber, can solve the problem of increased difficulty in wastewater treatment, affecting the degradation of cellulose and hemicellulose, cellulase and Cellulase degrades carbohydrates and other problems to achieve good penetration and diffusion performance, reduce the generation of pollutants, and reduce mechanical energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The co-production preparation method of bleached pulp, lignin carbon fiber and fuel ethanol lies in the following steps:

[0027] (1) Hemicellulose extraction

[0028] After the eucalyptus wood is cut into flakes and cleaned to remove sand and gravel, hemicellulose is hydrolyzed at 155°C for 120 minutes. During the hydrolysis process, lye is added to keep the pH value of the hydrolyzate at 7 to prevent acid hydrolysis of cellulose fibers; Filter the hemicellulose-containing hydrolyzate from the sheet-shaped eucalyptus raw material under normal pressure to obtain hemicellulose and lignin hydrolyzate;

[0029] (2) Hemicellulose extrusion extraction

[0030] During the hydrolysis process of the sheet-shaped eucalyptus raw material, the cellulose fiber absorbs water and swells, and part of the hemicellulose and lignin are hydrolyzed but not dissolved. Use a parallel twin-screw extruder to apply ≥ 1Mpa to the sheet-shaped eucalyptus raw material that has filtered out the hy...

Embodiment 2

[0038] The co-production preparation method of bleached pulp, lignin carbon fiber and fuel ethanol lies in the following steps:

[0039] (1) Hemicellulose extraction

[0040]After the eucalyptus is cut into flakes and cleaned to remove sand and gravel, hemicellulose is hydrolyzed at 155°C for 180 minutes. During the hydrolysis process, lye is added to keep the pH value of the hydrolyzate at 9 to prevent acid hydrolysis of cellulose fibers; Filter the hemicellulose-containing hydrolyzate from the sheet-shaped eucalyptus raw material under normal pressure to obtain hemicellulose and lignin hydrolyzate;

[0041] (2) Hemicellulose extrusion extraction

[0042] During the hydrolysis process of the sheet-shaped eucalyptus raw material, the cellulose fiber absorbs water and swells, and part of the hemicellulose and lignin are hydrolyzed but not dissolved. Use a parallel twin-screw extruder to apply ≥ 1Mpa to the sheet-shaped eucalyptus raw material that has filtered out the hydrolyz...

Embodiment 3

[0050] The co-production preparation method of bleached pulp, lignin carbon fiber and fuel ethanol lies in the following steps:

[0051] (1) Hemicellulose extraction

[0052] Poplar raw materials are cut into flakes, cleaned and removed of sand and gravel, then hydrolyzed hemicellulose at 165°C for 150 minutes, adding lye at the right time during the hydrolysis process to keep the pH value of the hydrolyzed solution at 8, so as to prevent acid hydrolysis of cellulose fiber; filtering the hemicellulose-containing hydrolyzate from the flaky poplar raw material under normal pressure by using a sieve to obtain the hemicellulose and lignin hydrolyzate;

[0053] (2) Hemicellulose extrusion extraction

[0054] During the hydrolysis process of flaky poplar raw materials, the cellulose fiber absorbs water and swells, and part of the hemicellulose and lignin are hydrolyzed but not dissolved. A parallel twin-screw extruder is used to apply ≥ 1Mpa to the flaky poplar raw material that ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com