A kind of surface modified nickel base electrode material

An electrode material and surface modification technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of improving cycle performance and rate performance, excellent lithium ion conductivity, and improving Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A surface-modified nickel-based electrode material includes a nickel-based material precursor, lithium acetate and yttria-stabilized bismuth oxide.

[0048] Further, the mass of the yttria-stabilized bismuth oxide accounts for 1% of the total electrode material.

[0049] Further, in the nickel-based material precursor, the material ratio of nickel, cobalt, and manganese is 85: 5:10, and in the surface-modified nickel-based electrode material, the ratio of lithium element, nickel element, cobalt element and manganese element is The molar ratio was 1.02:0.85:0.05:0.1.

[0050] The above materials were prepared into electrode materials for coating, and then made into button batteries for electrochemical performance testing. The obtained material has a specific capacity of 208mAh / g at 0.1C, and a capacity retention rate of 94% after 100 cycles at a rate of 1C. It is a positive electrode material for lithium batteries with excellent electrochemical performance.

[0051] Sp...

Embodiment 2

[0053] A surface-modified nickel-based electrode material includes a nickel-based material precursor, lithium acetate and dysprosium oxide-stabilized zirconia.

[0054] Further, the mass of the dysprosium oxide-stabilized zirconia accounts for 2% of the total electrode material.

[0055] Further, the mass ratio of nickel, cobalt and manganese in the nickel-based material precursor is 80:10:10, and the molar ratio of lithium element, nickel element, cobalt element and manganese element in the surface-modified nickel-based electrode material is 1.08:0.8:0.1:0.1.

[0056] The above materials were prepared into electrode materials for coating, and then made into button batteries for electrochemical performance testing. The obtained material has a specific capacity of 200mAh / g at 0.1C, and a capacity retention rate of 90% after 100 cycles at a rate of 1C, which is a positive electrode material for lithium batteries with excellent electrochemical performance.

[0057] Specifically...

Embodiment 3

[0059] A surface-modified nickel-based electrode material includes a nickel-based material precursor, lithium acetate and samarium oxide-stabilized tin oxide.

[0060] Further, the mass of the samarium oxide-stabilized tin oxide accounts for 1% of the total electrode material.

[0061] Further, the mass ratio of nickel, cobalt, and manganese in the nickel-based material precursor is 90:5:5, and the molar ratio of lithium, nickel, cobalt, and manganese in the surface-modified nickel-based electrode material is is 1.06:0.9:0.05:0.05.

[0062] The above materials were prepared into electrode materials for coating, and then made into button batteries for electrochemical performance testing. The obtained material has a specific capacity of 218mAh / g at 0.1C, and a capacity retention rate of 92% after 100 cycles at a rate of 1C. It is a positive electrode material for lithium batteries with excellent electrochemical performance.

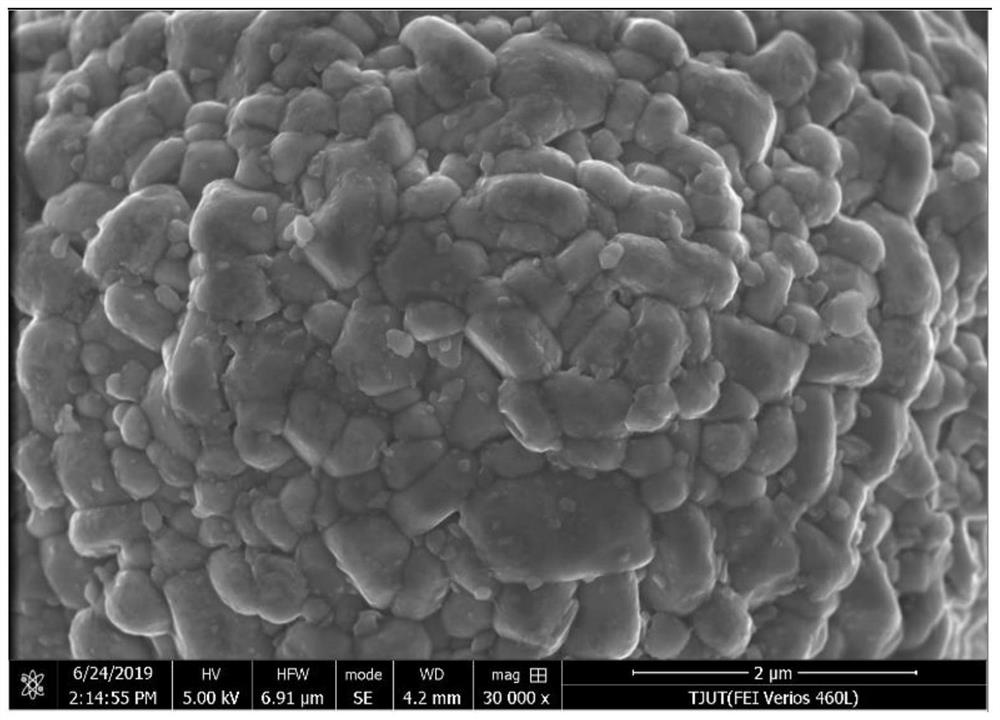

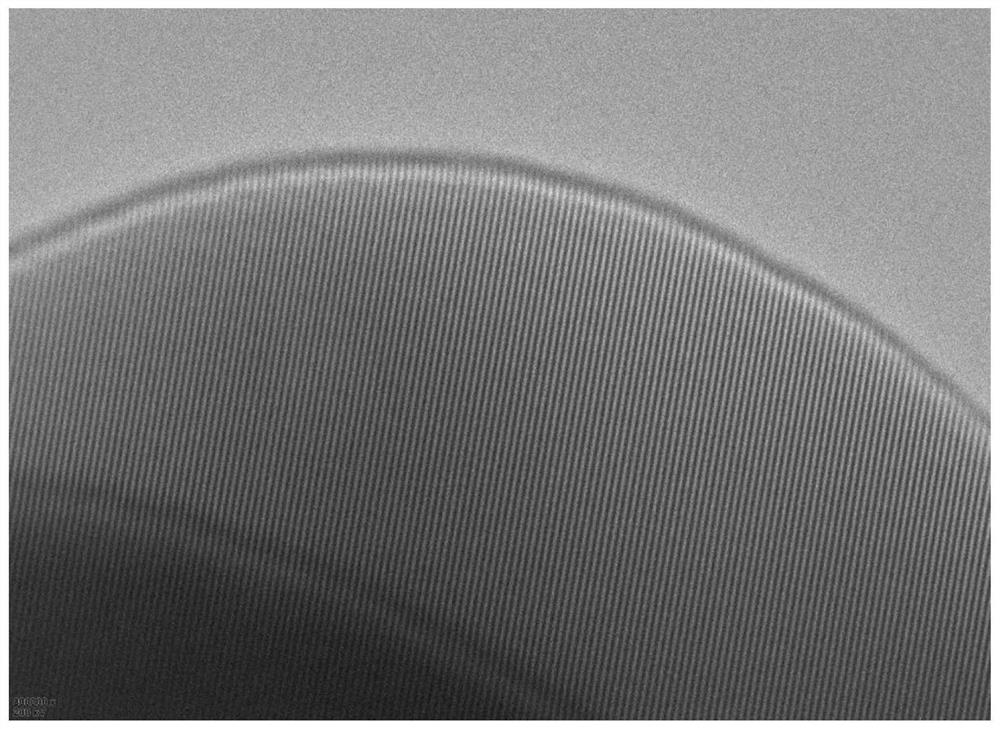

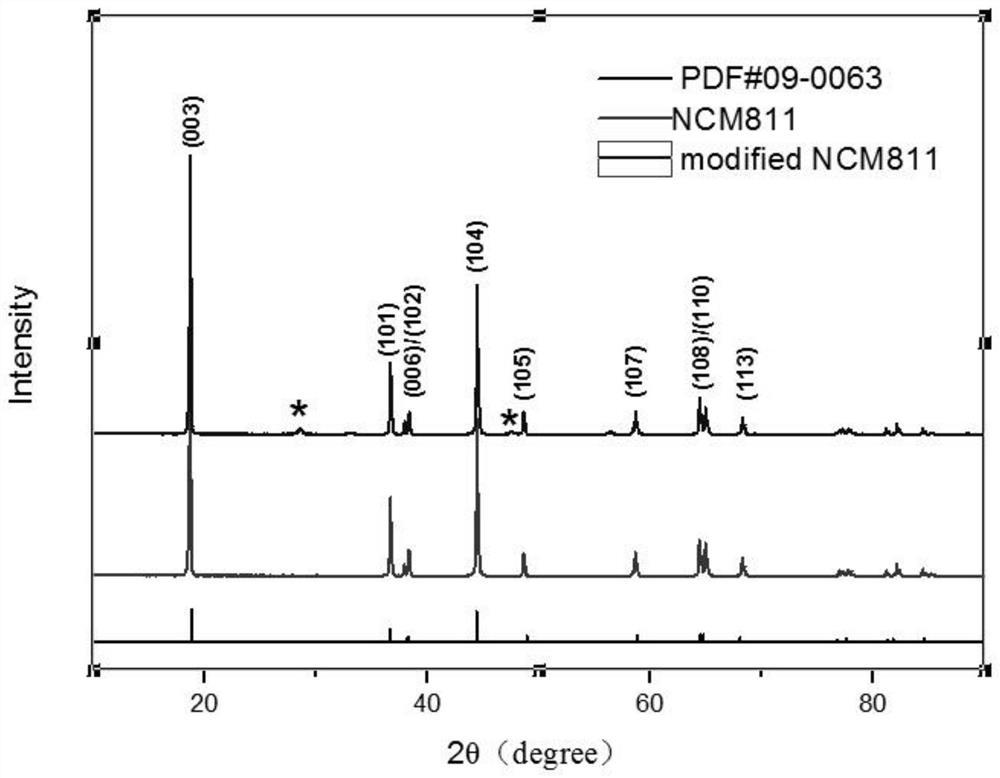

[0063] Specifically, with Figure 13 This is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com