A modified silicon carbon negative electrode material and its preparation method and application

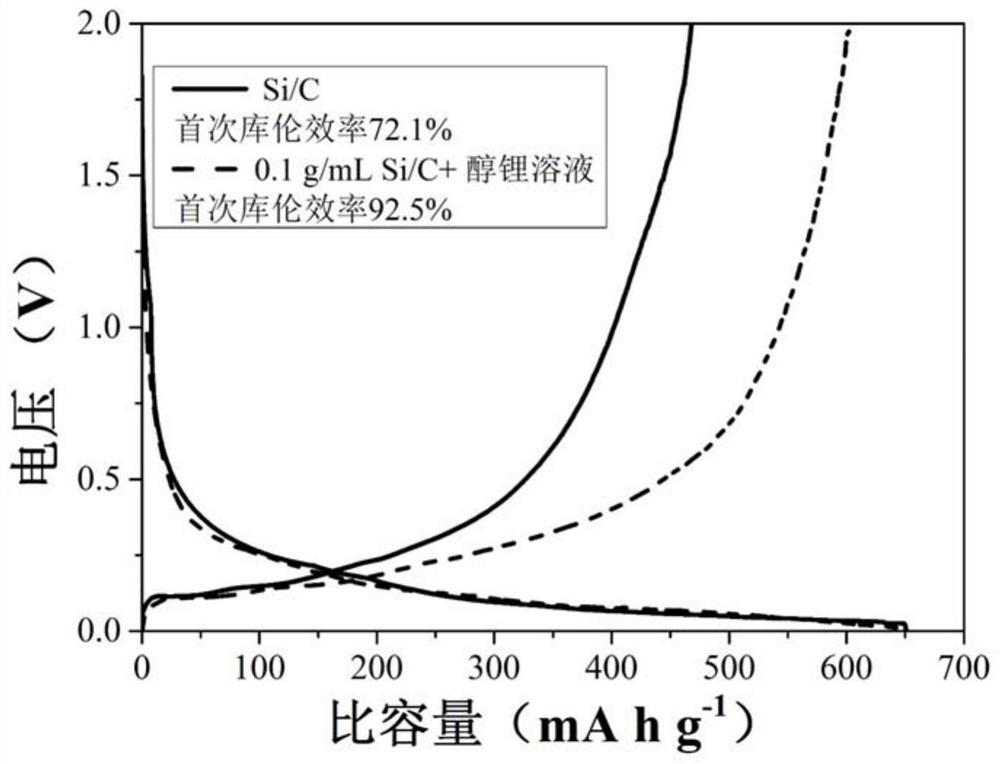

A carbon negative electrode material and negative electrode material technology, applied in the direction of negative electrode, active material electrode, silicon, etc., can solve the problems of complex process and high cost, achieve low cost and improve the effect of initial coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

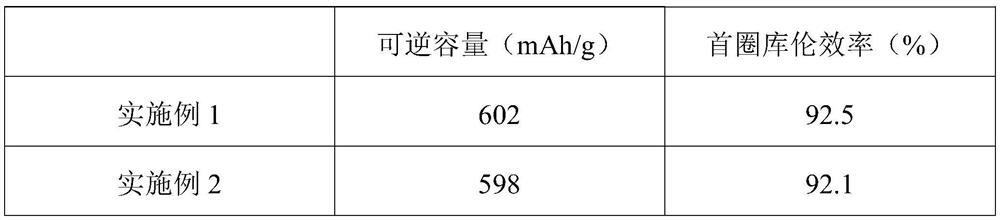

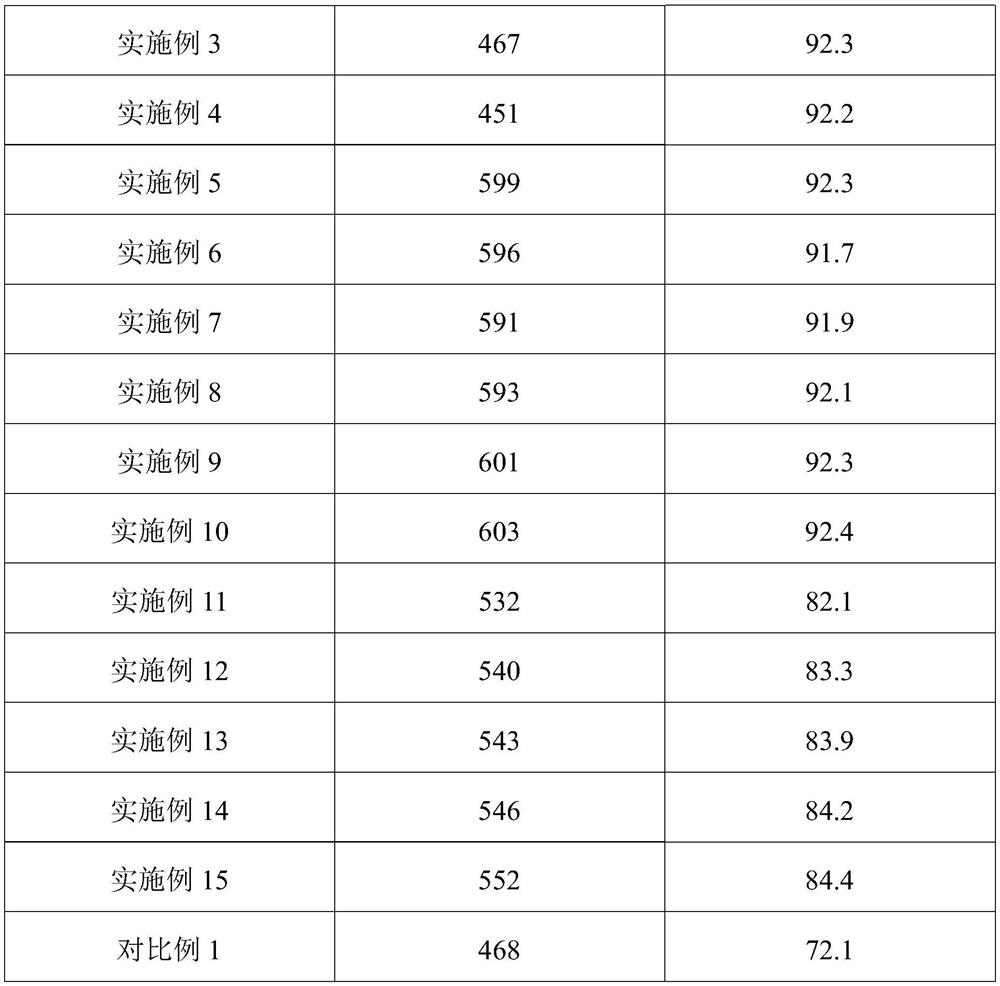

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing a modified silicon-carbon negative electrode material, the preparation method comprising the following steps:

[0044] (1) Mix silicon-carbon negative electrode material and lithium alkoxide solution at a solid-to-liquid ratio of 0.2:1, and perform a solvothermal reaction at 180° C. for 12 hours, and the unit of the solid-to-liquid ratio is g / mL;

[0045] (2) Alcohol washing step (1) The solid powder obtained after the solvothermal reaction was vacuum-dried at 60° C. for 24 hours to obtain a modified silicon-carbon negative electrode material;

[0046] The lithium alkoxide solution is mixed by metal lithium and alcohol solvent, the solid-liquid ratio of metal lithium and alcohol solvent is 1:1, and the unit of the solid-liquid ratio is mg / mL; the alcohol solvent is 2,2, 2-Trifluoroethanol.

[0047] The alcohol solvent used for the alcohol washing described in step (2) is the same as that used for configuring the lithium a...

Embodiment 2

[0050] This embodiment provides a method for preparing a modified silicon-carbon negative electrode material, the preparation method comprising the following steps:

[0051] (1) Mix silicon-carbon negative electrode material and lithium alkoxide solution at a solid-to-liquid ratio of 0.01:1, and perform a solvothermal reaction at 120° C. for 48 hours, and the unit of the solid-to-liquid ratio is g / mL;

[0052] (2) Alcohol washing step (1) The solid powder obtained after the solvothermal reaction was vacuum-dried at 70° C. for 20 hours to obtain a modified silicon-carbon negative electrode material;

[0053] The lithium alkoxide solution is mixed by metal lithium and alcohol solvent, the solid-liquid ratio of metal lithium and alcohol solvent is 0.1:1, and the unit of the solid-liquid ratio is mg / mL; the alcohol solvent is 2,2, 2-Trifluoroethanol.

[0054] The alcohol solvent used for the alcohol washing described in step (2) is the same as that used for configuring the lithiu...

Embodiment 3

[0057] This embodiment provides a method for preparing a modified silicon-carbon negative electrode material, the preparation method comprising the following steps:

[0058] (1) Mix silicon-carbon negative electrode material and lithium alkoxide solution at a solid-to-liquid ratio of 0.5:1, and perform a solvothermal reaction at 260° C. for 0.5 h, and the unit of the solid-to-liquid ratio is g / mL;

[0059] (2) Alcohol washing step (1) The solid powder obtained after the solvothermal reaction was vacuum-dried at 100° C. for 10 hours to obtain a modified silicon-carbon negative electrode material;

[0060] The lithium alkoxide solution is mixed by metal lithium and alcohol solvent, the solid-liquid ratio of metal lithium and alcohol solvent is 2:1, and the unit of the solid-liquid ratio is mg / mL; the alcohol solvent is 2,2, 2-Trifluoroethanol.

[0061] The alcohol solvent used for the alcohol washing described in step (2) is the same as that used for configuring the lithium alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com