Preparation method of bionic carbon negative electrode material used as potassium ion battery negative electrode, and product

A negative electrode material and battery negative electrode technology, applied in the field of biomimetic carbon and its preparation, can solve the problems of insufficient rate performance and fast charge/discharge characteristics, and achieve excellent electrochemical performance, high reversible capacity, and excellent rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

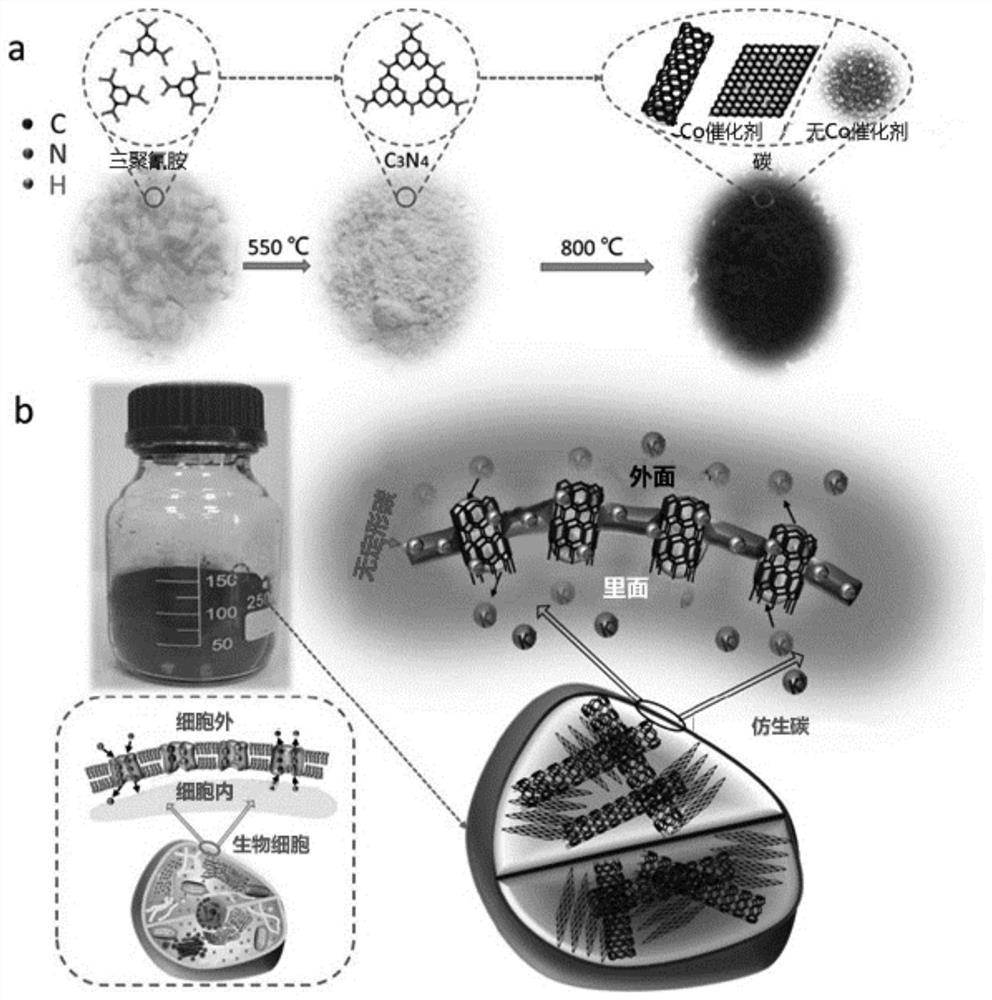

[0042] Such as figure 1 As shown, first, the preparation of nitrogen carbon compound (C 3 N 4 ) intermediate: 15 mg of melamine precursor was placed in a porcelain boat, and heated in a muffle tube furnace at 2 °C min -1 The heating rate is heated to 550°C, and kept at a constant temperature for 5h, and then naturally cooled to room temperature to obtain C 3 N 4 ;

[0043] Secondly, cobalt (Co) catalyst catalyzes high-temperature carbonization treatment: the C 3 N 4 Grind into fine powder, then mix with metal Co at a mass ratio of 1:1, and then fully mix in an agate mortar; after mixing evenly, put it into a porcelain boat, and heat it in a tube furnace with an argon atmosphere at 2°C min -1 Raise the temperature to 800°C at a certain rate, and heat it at this temperature for 2 hours, and then cool it naturally to room temperature;

[0044] Finally, acid treatment to remove the metal catalyst; repeated washing with 2mol / L hydrochloric acid (HCl) solution to remove Co, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com