A kind of antimony sulfide-based negative electrode material for lithium ion battery and preparation method thereof

A lithium-ion battery, antimony sulfide-based technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low capacity output, poor cycle stability, low first Coulombic efficiency, etc., to increase electronic conductivity , Relieve agglomeration and improve Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for an antimony sulfide-based negative electrode material for a lithium ion battery, comprising the following steps:

[0031] Step 1: placing antimony trioxide, expanded graphite and sulfur powder in a ball mill jar to obtain a premixed material; the mass ratio of described antimony trioxide, expanded graphite and sulfur powder is preferably (0.2-0.6):( 0.05-0.15): (0.4-0.6), more preferably 0.3:0.1:0.5, the sources of described antimony trioxide and sulfur powder are all commercially available, and expanded graphite is made of commercial expandable graphite in a room full of inert atmosphere It is obtained by treating in a tube furnace at a high temperature of 1000°C for 1 minute, and the heating rate is 10°C / min. The size of antimony trioxide is micron or below, preferably an average size of 700nm, the diameter of expandable graphite is preferably 75 microns, the sulfur powder is preferably sublimed sulfur, and the ball milling tank is preferably ...

Embodiment 1

[0038] 1) Weigh 0.3g of antimony trioxide (size 700nm) and 0.1g of expanded graphite according to the mass ratio of 3:1:5. , the heating rate is 10 degrees per minute, and the expandable graphite diameter is 75 microns) and 0.5g sublimated sulfur powder material in a low-energy planetary ball mill tank to obtain a premixed material;

[0039] 2) According to the mass ratio of ball to material of 50:1, weigh the ball milling beads made of zirconia and mix them with the premixed material in the above step 1), the ball milling time is 30h, and the speed is 400r / min to obtain antimony trioxide / expanded graphite / Sulfur powder ternary mixed material.

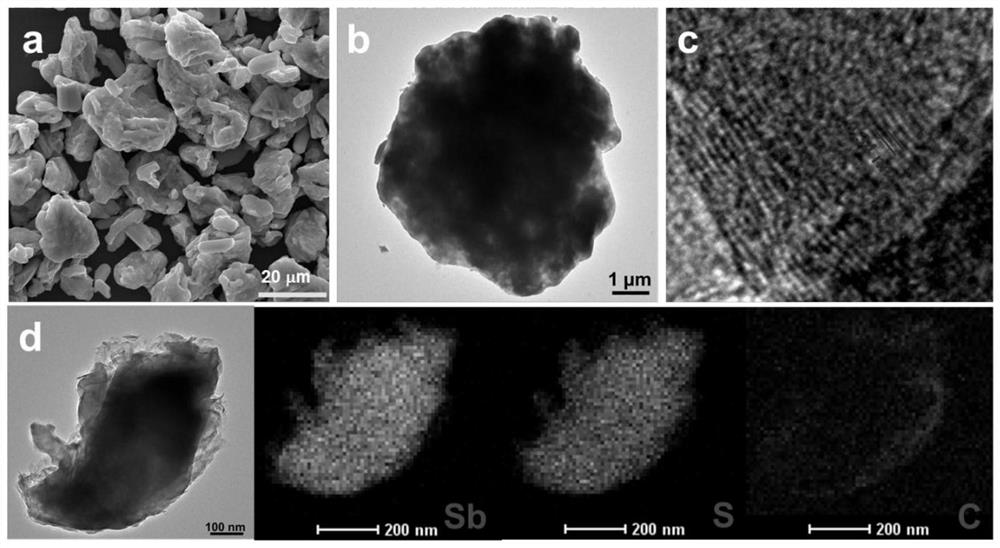

[0040] 3) The ternary mixed material obtained in the above step 2) is annealed at a temperature of 500° C. for 2 hours in an argon protective gas, and then the antimony sulfide-based negative electrode material Sb for lithium ion batteries is obtained. 2 S 3 @EG'-S.

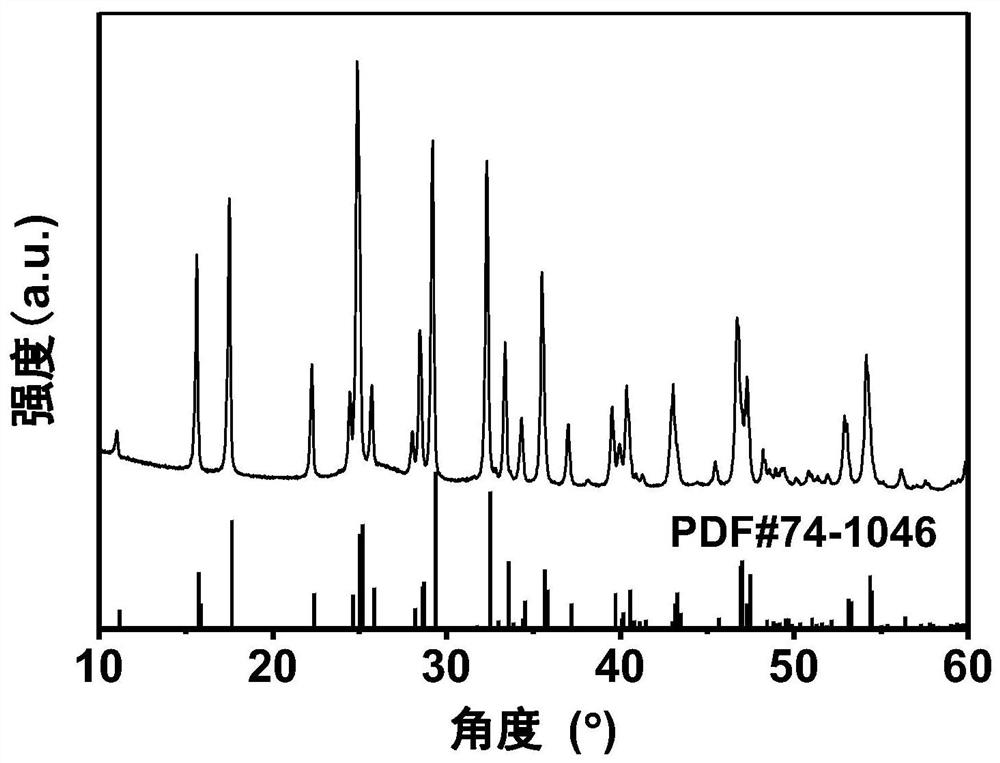

[0041] Embodiment 1 gained Sb 2 S 3 The XRD pattern of @EG’-S...

Embodiment 2

[0044] The preparation method and conditions are the same as in Example 1, except that the ball milling time is 8h and 15h.

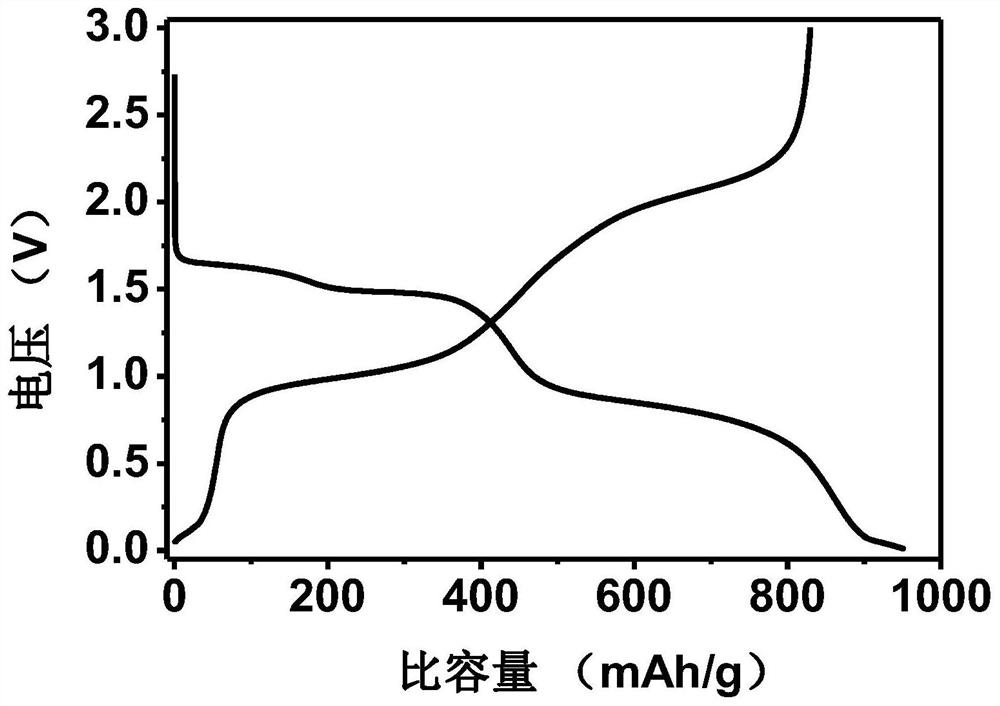

[0045] Figure 7 For the Sb obtained in Example 2 2 S 3 The first charge and discharge curves of the @EG’-S composite anode material for the lithium half-cell at a voltage range of 0.01-3.0V and a current density of 200mA / g when the ball milling time is 8h and 15h. When the ball milling time is 8 hours, the first discharge specific capacity is 890.9mAh / g, the first charge specific capacity is 730.4mAh / g, and the first Coulombic efficiency is 82%; when the ball milling time is 15 hours, the first discharge specific capacity is 930.1mAh / g, and the first charge specific capacity is 772.9mAh / g, the first Coulombic efficiency was 83.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com