A flexible aqueous zinc-ion battery

A zinc-ion battery and water-based technology, applied in the field of flexible energy storage, can solve problems such as complex manufacturing process, poor cycle performance, and low energy density, and achieve the goals of avoiding potential safety hazards, good packaging effect, and reducing contact resistance and battery internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

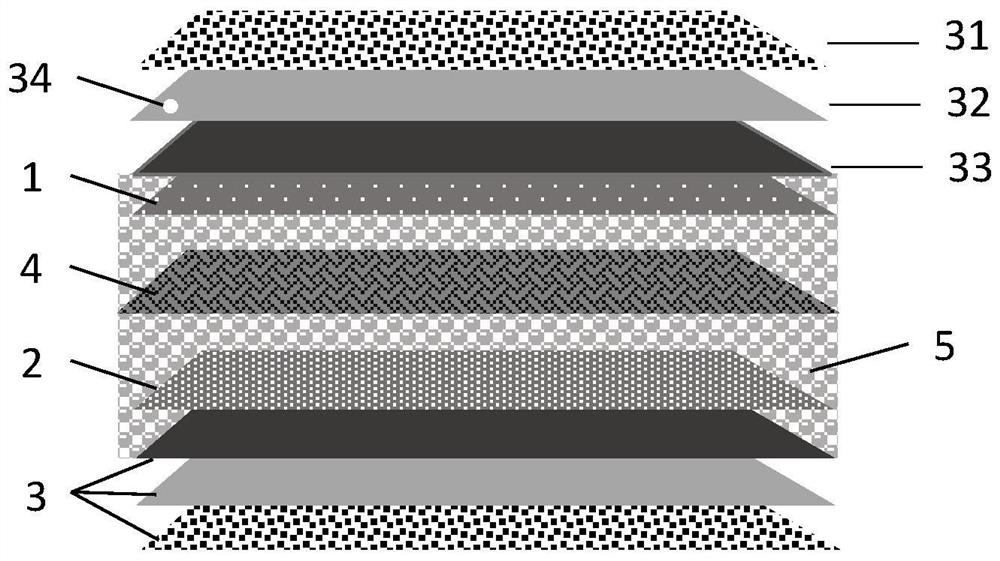

[0033] like figure 1 As shown, a flexible water-based zinc-ion battery includes a positive electrode layer 1, a negative electrode layer 2, a current-collecting layer 3, a separator 4 and an aqueous electrolyte 5, and the current-collecting layer 3 includes a gas-permeable layer 31, a matrix layer 32 and a conductive layer 33 , there is an opening 34 on the base layer.

[0034]First, the high-density polyethylene film is used as the air-permeable layer, and the polyethylene terephthalate (PET) film with a 1mm opening is used as the base layer, and one side of the base layer is combined with the air-permeable layer, and then the graphene The slurry is coated on the other side of the base layer to form a conductive layer, thereby forming a current-collecting layer structure of a breathable layer-base layer-conductive layer, and a polyethylene terephthalate (PET) film base layer and a breathable layer or a conductive layer Before lamination, the surface is cleaned by ultrasonic ...

Embodiment 2

[0039] A flexible water-based zinc-ion battery includes a positive electrode layer, a negative electrode layer, a current-collecting layer, a separator, and an aqueous electrolyte. First, the high-density polyethylene film is used as the air-permeable layer, and the polyethylene naphthalate (PEN) film with three 0.5mm openings is used as the base layer, and the carbon nanotube slurry is coated on one side of the base layer to form conductive layer, and then compound the air-permeable layer with the other side of the matrix layer to form a current-collecting layer structure of air-permeable layer-matrix layer-conductive layer, polyethylene naphthalate (PEN) film base layer and air-permeable layer or The surface of the conductive layer is cleaned by a plasma cleaning machine before compounding.

[0040] Then, use niobium-doped manganese dioxide as the positive electrode active material, mix the binder, the conductive agent Super-P and CNT to obtain the positive electrode slurry;...

Embodiment 3

[0046] A flexible water-based zinc-ion battery includes a positive electrode layer, a negative electrode layer, a current-collecting layer, a separator, and an aqueous electrolyte. First, the meta-aramid fiber film is used as the air-permeable layer, and the polyvinyl alcohol (PVA) film with five 0.12mm openings is used as the base layer, and one side of the base layer is combined with the air-permeable layer, and then the graphene slurry is coated. Cover the other side of the base layer to form a conductive layer, and then form a gas-permeable layer-base layer-conductive layer structure of the current-collecting layer. The polyvinyl alcohol (PVA) film base layer is cleaned by an ultrasonic cleaning machine before being combined with the gas-permeable layer or conductive layer. Its surface is cleaned.

[0047] Then, use carbon-coated manganese monoxide as the positive electrode active material, mix the binder, conductive agent Super-P and KS-6 to obtain the positive electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com